Metric Bore Sprocket for ISO 20B Roller Chain (31.75mm Pitch)

Metric Bore Sprocket for ISO 606 and DIN 8187 20B Roller Chain

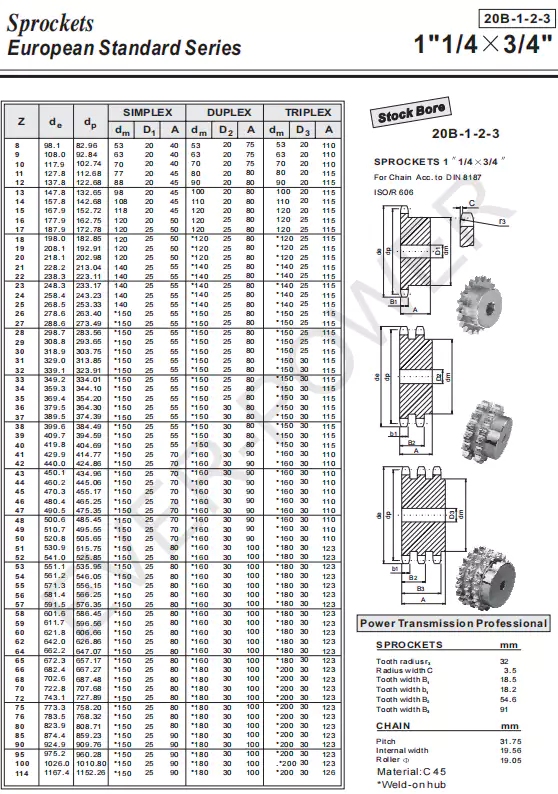

The Metric Bore Sprocket is specifically designed for ISO 606 and DIN 8187 20B roller chains, featuring a 31.75mm pitch. This durable sprocket ensures efficient power transmission and optimal performance in various applications.

GBC provides high-quality Metric Bore Sprockets in Australia, ensuring reliability and performance for all your needs.

Specifications for Metric Bore Sprocket for ISO 20B Roller Chain (31.75mm Pitch)

A metric bore sprocket is specifically designed to accommodate a metric bore size with a standard keyway slot. This type of sprocket is engineered for compatibility with ISO 20B roller chains, which have a pitch of 31.75mm. The Metric Bore Sprocket for ISO 20B Roller Chain is a notable example of a metric bore sprocket, widely utilized across various industrial applications due to its reliability and efficiency.

Customization of Sprockets

Customizing a sprocket involves several critical factors:

- Material: Sprockets can be constructed from diverse materials, including high carbon steel, alloy steel, and stainless steel. The material choice is influenced by the specific application, environmental conditions, and budget constraints.

- Tooth profile: The design of the tooth profile affects how the sprocket meshes with the chain, with common profiles being standard, double pitch, and specialized shapes.

- Number of teeth: The total number of teeth plays a significant role in determining the speed ratio and torque transmission capabilities of the sprocket.

- Size: The dimensions of a sprocket are determined by the chain pitch and the number of teeth, impacting both fit and performance.

- Center bore: The center bore is the essential opening in the sprocket that fits onto the shaft. It must be precisely sized and shaped to ensure proper alignment and secure fit.

- Keyway slot: This groove within the center bore allows a key to fit, preventing the sprocket from rotating inadvertently on the shaft, which is vital for maintaining operational integrity.

- Surface treatment: Various surface treatments are applied to enhance protection against corrosion and wear. Common methods include plating, painting, and powder coating to extend the sprocket's lifespan.

Materials and Manufacturing Process Used in Our Sprockets

At GBC - Ever-power Australia Agency, our sprockets are manufactured using high-quality materials, such as high carbon steel, alloy steel, or stainless steel. The manufacturing process comprises several key steps:

- Material selection: We prioritize selecting the most suitable material for each specific application to guarantee both strength and durability.

- Cutting: The material is shaped to the required dimensions using advanced cutting techniques, including laser cutting, plasma cutting, or waterjet cutting, ensuring precision.

- Forming: The material is then formed into its desired shape through methods like forging, casting, or extrusion, which contribute to its structural integrity.

- Machining: The sprocket undergoes machining to achieve exact dimensions and tolerances, utilizing various methods such as turning, milling, drilling, or grinding.

- Heat treatment: A heat treatment process is applied to enhance the mechanical properties such as hardness and strength. This may include techniques like quenching, tempering, and annealing.

- Surface treatment: Protective coatings, like zinc plating or black oxide, are applied to prevent corrosion and enhance wear resistance, ensuring long-term reliability.

- Quality control: Comprehensive quality control measures, including dimensional checks and hardness tests, are conducted to verify that each sprocket meets stringent specifications before shipment.

Applications of Sprockets

Our sprockets find application across a diverse range of industries, including:

- Heavy machinery and equipment: Used extensively in construction equipment, mining machinery, and agricultural machinery, where durability and strength are crucial.

- Food processing and packaging: Essential in conveyor systems utilized for food processing and packaging, ensuring efficient transport of products.

- Chemical and pharmaceutical: Integral to chemical processing equipment and pharmaceutical machinery, where precision and reliability are paramount.

- Assembly lines: Employed in various assembly line equipment and automation systems to enhance operational throughput.

- Logistics and warehousing: Applied in conveyor systems for efficient material handling and storage solutions within warehouses.

Maintenance and Troubleshooting of Sprockets

Regular maintenance and inspection are essential for ensuring optimal sprocket performance. The following maintenance tips are recommended:

- Daily inspection: Check the sprocket for signs of wear, damage, or misalignment to ensure it functions correctly.

- Cleaning: Regularly remove dirt, debris, or any buildup on the sprocket using a brush or rag to maintain its efficiency.

- Lubrication: Apply appropriate lubricant to the sprocket to reduce friction and wear, prolonging its lifespan.

- Adjustment: Regularly adjust the chain tension and alignment to ensure a proper engagement with the sprocket, which is essential for smooth operation.

Common issues with sprockets include:

- Jumping teeth: Verify that the chain tension is adequate, and check for proper alignment. Replace the sprocket if excessive wear is detected.

- Fracture: Inspect for signs of overload or inappropriate material selection for specific applications, replacing the sprocket if necessary.

- Wear: Ensure proper lubrication of the sprocket and check the condition of the chain; replace components as needed.

- Noise: Investigate the cleanliness and lubrication of the sprocket and chain; adjust tension as required to mitigate noise.

- Sprocket slipping: Ensure the key is appropriately fitted and secured; replace the key if it has become worn or damaged.

Metric Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we pride ourselves on being one of the best sprocket suppliers in Australia. Our company specializes in Metric Bore Sprockets for ISO 20B Roller Chain (31.75mm Pitch), ensuring that our products meet the highest industry standards. We focus on delivering top-quality sprockets that provide maximum performance and durability, making them ideal for various applications.

At GBC, we understand the importance of excellent customer service. Our pre-sales support ensures that you find the right sprocket for your needs, while our after-sales service is dedicated to assisting you with any concerns or questions you may have. Furthermore, we offer non-standard customizations based on our clients' specifications, providing tailored solutions that meet specific operational requirements.

Additional information

| Edited by | Sylvia |

|---|

Metric Bore Sprocket for ISO 606 and DIN 8187 20B Roller Chain

The Metric Bore Sprocket is specifically designed for ISO 606 and DIN 8187 20B roller chains, featuring a 31.75mm pitch. This durable sprocket ensures efficient power transmission and optimal performance in various applications.

GBC provides high-quality Metric Bore Sprockets in Australia, ensuring reliability and performance for all your needs.