Metric Bore Sprocket for ISO 24B Roller Chain (38.1mm Pitch)

Metric Bore Sprocket for ISO 606 and DIN 8187

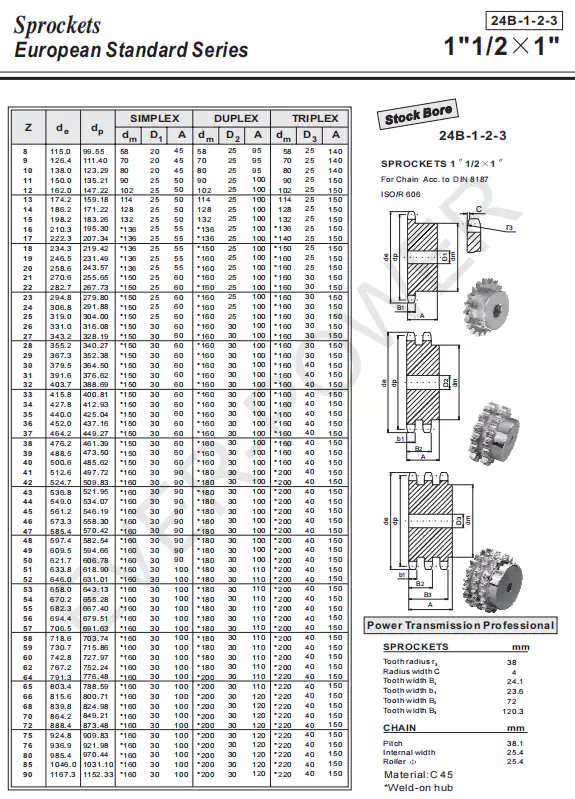

This Metric Bore Sprocket is specifically designed for 24B roller chains with a pitch of 38.1mm, ensuring reliable performance and durability. It is ideal for various industrial applications, providing optimal power transmission and efficiency.

GBC offers high-quality Metric Bore Sprockets in Australia to meet your operational needs.

Specifications for Metric Bore Sprocket for ISO 24B Roller Chain (38.1mm Pitch)

A metric bore sprocket is specifically engineered to function seamlessly within mechanical systems. It serves as a critical component in transferring torque and rotation, connecting a driving shaft to a driven element, often a chain. The bore size of these sprockets is standardized to fit a precise shaft diameter, facilitating easy installation and optimal performance. The Metric Bore Sprocket for ISO 24B Roller Chain is designed to meet these specifications while ensuring reliability and efficiency in power transmission.

Basic Structure and Customization of Sprockets

- Materials: Sprockets can be constructed from various materials such as high carbon steel, alloy steel, or stainless steel, chosen based on the specific requirements of the application.

- Tooth Profile: The design of the tooth profile is pivotal, influencing engagement dynamics and overall performance. Common profiles include standard, double pitch, and specialty configurations tailored for different operational demands.

- Number of Teeth: The quantity of teeth on a sprocket directly affects the speed ratio and torque transmission capabilities, which are vital for effective operation in mechanical systems.

- Dimensions: Sprockets come in various sizes, allowing them to accommodate different chain widths and pitch sizes, ensuring compatibility across various applications.

- Bore: The bore size of a sprocket must match the shaft diameter it is intended to fit, promoting secure and stable connections.

- Keyway: Many sprockets feature keyways, which are essential for maintaining proper alignment and preventing unwanted rotational slippage during operation.

- Surface Treatment: To enhance durability, sprockets may undergo surface treatments such as rust prevention coatings, which are crucial for extending their operational lifespan.

Materials and Manufacturing Process

Our metric bore sprockets are crafted from high carbon steel or alloy steel, selected based on application-specific needs. The manufacturing process includes several critical steps: material selection, cutting, stamping or forging, machining (which encompasses turning, milling, and drilling), heat treatment (including quenching, tempering, and surface hardening), followed by surface treatment (such as anti-rust coatings). This meticulous process ensures that every sprocket meets stringent quality standards, guaranteeing reliability and performance in demanding environments.

Applications

- Heavy Machinery and Equipment: These sprockets find extensive use in heavy-duty machinery and equipment, including construction machinery, mining equipment, and agricultural applications, where strength and reliability are paramount.

- Food Processing and Packaging: In the food industry, sprockets are integral to processing and packaging machines, ensuring smooth and efficient operations that adhere to strict hygiene standards.

- Chemical and Pharmaceutical: Our sprockets are ideal for chemical and pharmaceutical processing equipment, where precision, cleanliness, and durability are critical for maintaining operational integrity.

- Assembly Lines: Within assembly line systems, sprockets play a vital role, enabling the efficient movement and synchronization of components, which is crucial for maintaining productivity.

- Logistics and Warehousing: Sprockets are also employed in conveyor systems, facilitating effective material handling and logistics operations in warehouses and distribution centers, thus enhancing overall efficiency.

Maintenance and Troubleshooting

- Daily Inspection: It is essential to conduct regular inspections of sprockets to identify any signs of wear, damage, or misalignment, which can affect performance.

- Cleaning: Keeping the sprocket clean is vital; it should be free from dirt, debris, and excessive lubrication, which can impair its functionality.

- Lubrication: Proper lubrication is crucial to reduce friction and prolong the lifespan of the sprocket, contributing to smoother operation.

- Adjustment and Calibration: Periodic checks and adjustments of the chain’s tension and alignment are necessary to ensure optimal performance and prevent operational issues.

- Common Issues and Solutions: Frequently encountered problems with sprockets may include tooth skipping, breakage, wear, excessive noise, and chain derailment. Solutions vary based on the specific problem and may involve replacing the sprocket, repairing or replacing the chain, or realigning and adjusting tension.

Plain Bore Sprockets Supplier - GBC

GBC is the exclusive sales agent for Ever-power Group in Australia, and we are recognized as one of the best sprocket suppliers in the region. Our specialization includes the Metric Bore Sprocket for ISO 24B Roller Chain (38.1mm Pitch), which exemplifies our commitment to quality and precision engineering.

At GBC, we ensure that our sprockets meet the highest industry standards, providing durability and reliability for various applications. Our dedicated pre-sales and after-sales service teams are always ready to assist customers, ensuring a smooth purchasing experience and ongoing support. We pride ourselves on our responsiveness and customer satisfaction.

Additionally, GBC offers non-standard customization according to specific customer requirements, allowing us to cater to unique project needs efficiently.

Additional information

| Edited by | Sylvia |

|---|

Metric Bore Sprocket for ISO 606 and DIN 8187

This Metric Bore Sprocket is specifically designed for 24B roller chains with a pitch of 38.1mm, ensuring reliable performance and durability. It is ideal for various industrial applications, providing optimal power transmission and efficiency.

GBC offers high-quality Metric Bore Sprockets in Australia to meet your operational needs.