Plain Bore Sprocket NK11SB (3.7465mm Pitch)

The Plain Bore Sprocket NK11SB features a precise pitch of 3.7465mm, designed for optimal performance in various applications. Its durable construction ensures longevity and reliability, making it a preferred choice for engineers. GBC is proud to offer high-quality Plain Bore Sprockets in Australia, ensuring superior performance and customer satisfaction.

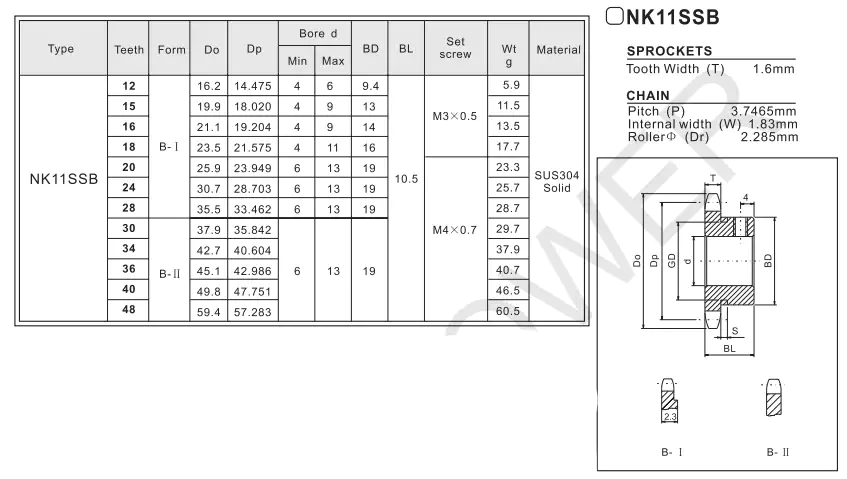

Specifications for Plain Bore Sprocket NK11SB (3.7465mm Pitch)

A plain bore sprocket is a specific type of sprocket widely utilized in various industrial applications. It serves as a crucial element in power transmission systems, particularly in machinery and equipment that depend on the transfer of rotational motion. This transfer is typically facilitated through the use of a chain drive, which effectively communicates the power generated by a motor or engine to different components within a machine.

Basic Structure of a Sprocket

The structure of a sprocket comprises several fundamental elements that are critical when customizing it for particular applications. These elements include:

- Material: The choice of material for the sprocket significantly influences its strength, durability, and wear resistance. Commonly used materials include high-carbon steel, alloy steel, and stainless steel, each offering unique properties suitable for different environments and loads.

- Tooth Profile: The configuration of the teeth on the sprocket plays a vital role in how effectively the chain engages with it. Variations in tooth profiles are designed to accommodate different chain types, ensuring optimal performance in various applications.

- Number of Teeth: The total number of teeth on the sprocket has a direct impact on the speed ratio and torque transfer between the driving and driven shafts, making it a crucial factor in design considerations.

- Dimensions: The overall dimensions, such as outer diameter and width, must be accurately defined to meet the specific requirements of the application, ensuring compatibility with other components.

- Bore Size: The bore size, representing the diameter of the center hole in the sprocket, must align with the shaft diameter to ensure proper installation and functionality.

- Keyway: A keyway is a slot present in the bore, allowing for the insertion of a key that prevents rotational slippage, ensuring a secure connection between the sprocket and the shaft.

- Surface Treatment: To enhance corrosion resistance, the sprocket's surface may undergo various treatments, such as rust prevention coatings or plating, which contribute to its longevity and reliability.

Materials and Manufacturing Process

Our plain bore sprockets are constructed from high-carbon steel, alloy steel, or stainless steel, selected based on the specific demands of the application. The manufacturing process includes several key steps:

- Material Selection and Cutting: The appropriate material is carefully selected and cut into the desired shape for subsequent processing.

- Stamping and Forging: The material is subjected to stamping or forging processes to create the initial shape of the sprocket.

- Machining: Various machining techniques, including turning, milling, drilling, and tapping, are employed to achieve precise dimensions and tooth profiles.

- Heat Treatment: Heat treatment processes, such as quenching and tempering, are utilized to enhance the sprocket's hardness and overall strength.

- Surface Treatment: The final surface treatment is performed to prevent rust and to improve the durability of the sprocket.

- Quality Inspection: Each sprocket undergoes comprehensive quality inspections to ensure compliance with the required standards.

Plain Bore Sprockets Applications

Plain bore sprockets are versatile components that find applications across various industries, including:

- Heavy Machinery and Equipment: In heavy machinery, sprockets are integral to systems like conveyors, cranes, and excavators, where power transmission is crucial.

- Food Processing and Packaging: In the food industry, sprockets are essential to the operation of processing and packaging machinery, ensuring efficiency and hygienic practices.

- Chemical and Pharmaceutical: Sprockets are vital in chemical and pharmaceutical machinery, providing reliable power transmission in demanding conditions.

- Assembly Lines: They are fundamental in assembly line systems, enabling the smooth and accurate movement of components throughout the production process.

- Logistics and Warehousing: Sprockets are utilized in conveyor systems to facilitate efficient transportation and sorting of goods within logistics and warehousing operations.

Maintenance and Troubleshooting

To ensure optimal performance and longevity, regular maintenance and inspection of sprockets are crucial. Maintenance tasks should include:

- Daily Inspection: Conduct routine checks on the sprocket for signs of wear, damage, or misalignment, which can impact its functionality.

- Cleaning: Keeping the sprocket clean from dirt, debris, and contaminants is essential to maintain its performance and efficiency.

- Lubrication: Applying the correct lubricants to both the sprocket and chain reduces friction and extends their operational lifespan.

- Adjustment and Calibration: Regularly verify and adjust the chain tension and alignment to ensure smooth and effective operation.

Common issues associated with sprockets may include tooth skipping, breakage, wear, excessive noise, and chain detachment. Effective troubleshooting methods include:

- Tooth Skipping: Check for misalignment or worn teeth and make necessary adjustments or replacements.

- Breakage: Inspect the sprocket for any cracks or fractures and replace it if needed to maintain safety and performance.

- Wear: Monitor wear patterns and replace the sprocket when teeth show excessive wear to avoid further damage.

- Excessive Noise: Ensure proper lubrication is applied and check for any misalignment or damage to the components.

- Chain Detachment: Verify chain tension and ensure proper engagement with the sprocket to prevent disconnections.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, recognized as one of the best sprocket suppliers in Australia. We take pride in offering high-quality sprockets that cater to various industrial needs. Our Plain Bore Sprocket NK11SB, featuring a pitch of 3.7465mm, exemplifies our commitment to quality and precision engineering.

At GBC, we ensure that our products meet the highest standards, which is why our sprockets are manufactured using durable materials and advanced technology. We provide exceptional pre-sale and after-sale services, guiding our customers through the selection process and ensuring their satisfaction even after the purchase.

Moreover, we understand that each customer has unique requirements. Therefore, we offer non-standard customization options, allowing us to create sprockets tailored to your specific needs.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK11SB features a precise pitch of 3.7465mm, designed for optimal performance in various applications. Its durable construction ensures longevity and reliability, making it a preferred choice for engineers. GBC is proud to offer high-quality Plain Bore Sprockets in Australia, ensuring superior performance and customer satisfaction.