Plain Bore Sprocket NK120B/NK120C (38.1mm Pitch)

The Plain Bore Sprocket NK120B/NK120C features a 38.1mm pitch, designed for optimal performance in various machinery applications. Its robust construction ensures durability and reliability, making it an essential component for efficient power transmission. GBC proudly offers high-quality Plain Bore Sprockets in Australia to meet your industrial needs.

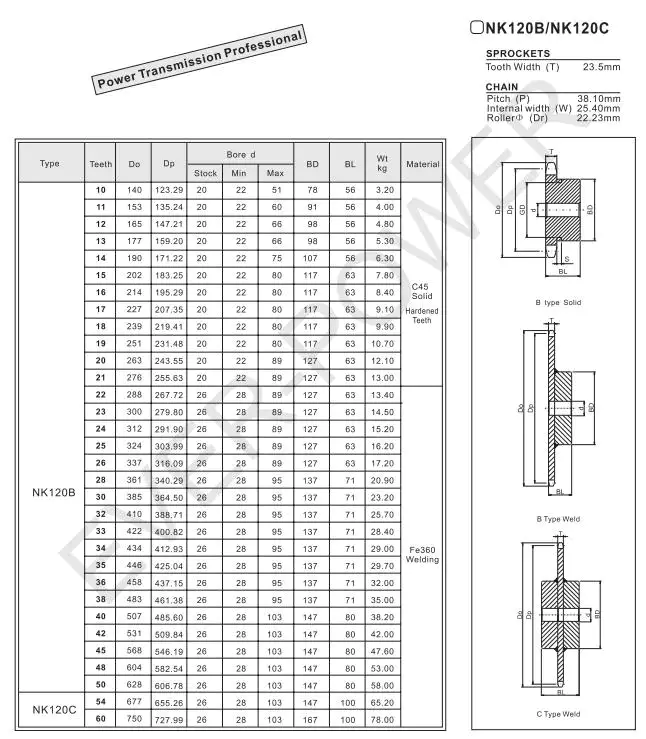

Specifications for Plain Bore Sprocket NK120B/NK120C (38.1mm Pitch)

A plain bore sprocket is a specialized type of sprocket characterized by its fixed center hole size, which is optimized for use in power transmission systems. These sprockets play a crucial role in transferring power between rotating shafts and chains efficiently. The design of the plain bore sprocket allows for a seamless fit onto specific shaft sizes, eliminating the need for any additional modifications or adaptations that could complicate installation.

Basic Structure of a Sprocket

A sprocket comprises several essential components that contribute to its overall functionality:

- Material: The choice of material for the sprocket is critical as it influences the component's strength, durability, and resistance to wear.

- Tooth Profile: The design of the teeth on the sprocket affects how the chain engages with the sprocket, impacting the efficiency of power transfer.

- Number of Teeth: The number of teeth influences both the speed ratio and torque transmission between the driving and driven shafts, making it an important design aspect.

- Size: The dimensions of the sprocket, including diameter and width, are key to ensuring a proper fit within the system.

- Center Bore: The center bore is the central hole that allows the sprocket to be mounted onto the shaft securely.

- Keyway: The keyway is a vital groove that helps prevent the sprocket from rotating independently of the shaft during operation.

- Surface Treatment: Treatments applied to the surface can enhance resistance to rust, corrosion, and wear, extending the lifespan of the sprocket.

Materials and Manufacturing Process

We manufacture our sprockets using high-quality materials such as high-carbon steel, alloy steel, or stainless steel. The selection of material is based on specific application requirements and desired properties, ensuring optimal performance.

The manufacturing process includes several steps to ensure the final product meets high standards:

- Material Selection: Carefully choosing the right material according to the desired specifications and characteristics is essential.

- Cutting and Stamping: The material is cut and stamped into the initial shape of the sprocket, which lays the foundation for subsequent processes.

- Machining: The sprocket undergoes machining techniques such as turning and milling, which refine the dimensions and shape of the teeth.

- Heat Treatment: This step enhances the sprocket's hardness and durability, making it suitable for demanding applications.

- Surface Hardening: The surface hardening process helps in resisting wear, ensuring the sprocket maintains its integrity over time.

- Surface Treatment: Treatments are applied to prevent rust and corrosion, protecting the sprocket in various environments.

- Quality Inspection: Each sprocket is subjected to rigorous testing to confirm that it meets predefined standards and specifications.

Applications

The NK120B/NK120C plain bore sprocket is versatile and finds applications across various industries, including:

- Heavy Machinery and Equipment: Used in construction and industrial machinery for reliable power transmission.

- Food Processing and Packaging: Essential in conveying systems to maintain hygiene and efficiency.

- Chemical and Pharmaceutical Industries: Employed in precision applications that require strict adherence to safety standards.

- Assembly Lines: Integral in automated assembly processes to ensure smooth operations.

- Logistics and Warehousing: Helps in material handling systems, enhancing productivity and efficiency.

Maintenance and Care

Regular maintenance and care are crucial for the optimal performance and longevity of the sprocket. The following maintenance steps should be routinely performed:

- Daily Inspection: Regularly check the sprocket for any signs of wear or damage to ensure it remains functional.

- Cleaning: Keep the sprocket free from dirt, debris, and lubricant residues to maintain its operational efficiency.

- Lubrication: Ensure appropriate lubrication is applied to minimize friction and prevent wear between the chain and sprocket.

- Adjustment and Calibration: Regularly verify that the sprocket is aligned correctly and adjusted for proper tension with the chain.

Common issues that may arise with sprockets include tooth skipping, breakage, and excessive noise. To address these problems effectively, consider the following solutions:

- Tooth Skipping: Adjust chain tension and alignment, replace worn components, and ensure proper lubrication is maintained.

- Breakage: Conduct inspections to identify cracks or damage, replacing any affected sprockets while addressing root causes of failures.

- Wear: Monitor the wear on teeth regularly and replace sprockets as needed to ensure continued reliability.

- Excessive Noise: Check for proper lubrication and alignment, making adjustments to mitigate noise.

- Chain Disengagement: Regularly inspect for tension and alignment issues, replacing any damaged or worn components.

In addition to the NK120B/NK120C plain bore sprocket, we provide a range of other sprocket varieties including platewheel sprockets, idler sprockets, QD sprockets, and taper lock sprockets. These alternatives cater to diverse power transmission needs, and we also offer complementary chains to ensure an efficient system.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are recognized as one of the best sprocket suppliers in Australia. Our commitment to quality is evident in our Plain Bore Sprocket NK120B/NK120C, which features a 38.1mm pitch, ensuring optimal performance and durability in various applications.

At GBC, we pride ourselves on providing exceptional pre-sales and after-sales service. Our knowledgeable team is ready to assist you in selecting the right sprocket for your needs and is dedicated to offering support long after the purchase. Customer satisfaction is our priority.

Moreover, we understand that every client has unique requirements. That’s why we offer non-standard customization options to meet specific demands, ensuring you receive the exact product that fits your application perfectly.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK120B/NK120C features a 38.1mm pitch, designed for optimal performance in various machinery applications. Its robust construction ensures durability and reliability, making it an essential component for efficient power transmission. GBC proudly offers high-quality Plain Bore Sprockets in Australia to meet your industrial needs.