Plate Wheel Sprocket 05B-1-2

The Plate Wheel Sprocket 05B-1-2 is designed for durability and efficiency, making it an ideal choice for various machinery applications. With its precise engineering and robust construction, this sprocket ensures optimal performance and longevity. GBC proudly offers high-quality Plate Wheel Sprockets in Australia, catering to your industrial needs.

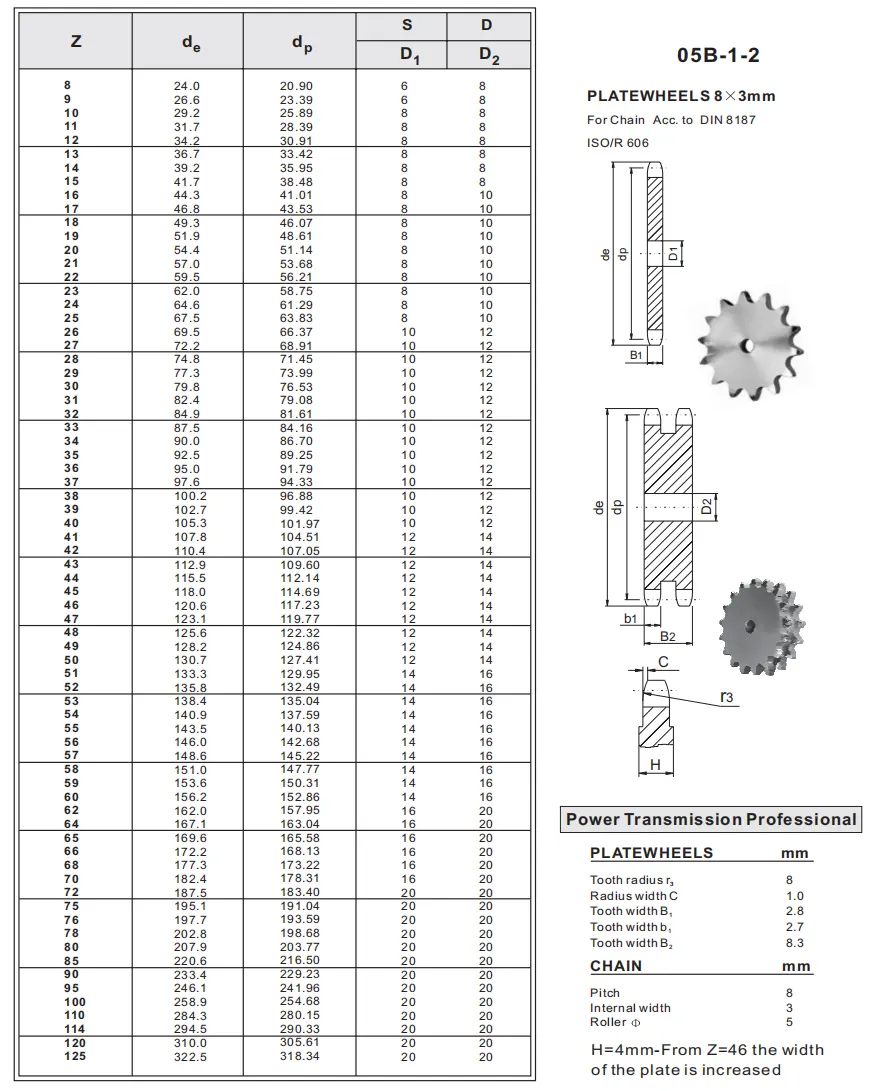

Specifications of Plate Wheel Sprocket 05B-1-2

Plate Wheel Sprocket 05B-1-2 is an essential component in various transmission systems, playing a crucial role in the transfer of power and motion between rotating shafts. This type of sprocket features a design that includes a robust hub, a precisely engineered set of teeth, and a durable plate that securely holds the teeth in place. The teeth engage seamlessly with the links of a chain, ensuring effective motion transfer while minimizing wear and tear. This design not only enhances efficiency but also guarantees long-lasting performance under various operational conditions.

Types of Plate Wheel Sprockets

Plate wheel sprockets are available in three primary types: single-row, double-row, and multi-row. Single-row sprockets consist of one set of teeth, making them ideal for applications with lower load requirements. In contrast, double-row sprockets feature two sets of teeth, allowing them to handle moderate loads and providing enhanced motion control. Multi-row sprockets, which have more than two sets of teeth, are designed for heavy-duty applications where higher load capacities and precise motion control are necessary. Each type offers unique advantages tailored to specific needs in transmission systems, ensuring that users can select the most suitable option for their applications.

Platewheel Sprocket - Product Features

Our Platewheel sprockets are crafted from premium materials that provide outstanding resistance to corrosion and wear, ensuring prolonged durability and strength. They are specifically designed to be lightweight while still maintaining the structural integrity necessary for high-performance applications. The manufacturing process focuses on precision, resulting in products that meet rigorous quality standards. Additionally, our sprockets undergo surface treatments that enhance their performance by reducing friction and protecting against environmental factors. This attention to detail in both design and material selection ensures that our sprockets perform exceptionally in various conditions.

Material Advantages

Our sprockets are produced using high-quality materials that deliver exceptional corrosion resistance, wear resistance, and strength. This selection of materials includes carbon steel, known for its toughness and durability, stainless steel, which offers superior corrosion resistance, and plastic, which is lightweight and resistant to various chemicals. Each material option is carefully chosen to meet the diverse application requirements of our customers. By providing various material choices, we ensure our clients can select the most suitable option for their specific conditions, enhancing performance and lifespan.

Design Features

Our sprockets are designed with a focus on being lightweight yet robust, promoting maximum performance and durability in all applications. The precision manufacturing process ensures that every component fits together perfectly, optimizing the engagement between the sprocket and chain. Additionally, we offer several surface treatments such as black oxide, zinc plating, and anodizing, which provide further protection against corrosion and wear. These treatments not only enhance the aesthetic appeal of the sprockets but also significantly increase their operational lifespan, making them a reliable choice for any transmission system.

Services We Offer

We provide a comprehensive range of services tailored to meet various customer needs, including custom design, material selection, surface treatment, hardening, and custom packaging. Our dedicated team is committed to delivering timely and cost-effective solutions that align with your specific requirements, ensuring satisfaction and quality in every project.

Custom Design

Our team of experienced engineers collaborates closely with clients to create custom sprockets that meet unique application specifications. Utilizing advanced design software and the latest manufacturing techniques, we ensure that our sprockets adhere to the highest quality standards, allowing for optimal performance and compatibility with existing systems.

Material Selection

We provide an extensive range of material options, including carbon steel, stainless steel, and plastic, allowing customers to choose the most suitable material for their applications. Our knowledgeable team assists clients in selecting the right material based on critical factors such as corrosion resistance, wear resistance, and the required strength for specific operational conditions, ensuring the sprockets are fit for purpose.

Surface Treatment

To enhance the performance and durability of our sprockets, we offer a variety of surface treatments. Options like black oxide, zinc plating, and anodizing are available, providing additional protection against corrosion and wear. Our experts can guide you in selecting the ideal surface treatment based on your application needs, ensuring your sprockets remain operational under challenging conditions.

Hardening

We provide several hardening options, including quenching and tempering, induction hardening, and carburizing, which enhance the strength and durability of our sprockets. Our technical team can assist in identifying the most suitable hardening method based on your specific application requirements, ensuring optimal performance and longevity of the sprockets.

Custom Packaging

We understand the importance of packaging in maintaining product integrity during transportation. Therefore, we offer custom packaging solutions that cater to your specific needs, including individual packaging, bulk packaging options, and customized labeling. Our team works with you to determine the best packaging strategy based on your shipping and handling requirements, ensuring your products arrive safely and in excellent condition.

Chain Sprocket Manufacturing Process

Our chain sprockets are produced through a meticulous manufacturing process that encompasses several stages: forging, machining, hobbing, teeth heating, quenching, surface treatment, quality inspection, packing, and shipping. This structured approach ensures each sprocket meets the high standards expected by our clientele.

Forging

The initial stage involves heating raw materials and shaping them with a forging press. This process is crucial for achieving the basic structure of the sprocket, ensuring that it possesses the necessary strength to perform effectively in its intended application.

Machining

After forging, the sprocket undergoes several machining techniques, including drilling, milling, and turning, to achieve precise dimensions and a smooth finish. This stage is vital for ensuring the sprocket fits perfectly within its operational system and operates efficiently.

Hobbing

Teeth are cut into the sprocket using advanced hobbing machines, which ensure consistent tooth profiles for optimal chain engagement. This process is essential for the sprocket's functionality, as it directly affects the transmission of power and motion.

Teeth Heating

The teeth of the sprocket are then heated to a specific temperature to enhance their strength and durability. This treatment is crucial for ensuring that the sprocket can withstand the high stresses involved in its operation.

Treated on Quenching

Following the heating process, the sprocket is quenched in either oil or water, which creates a hardened surface layer. This treatment is integral to improving the overall durability of the sprocket, making it more resistant to wear during usage.

Surface Treatment/Rust-Proof Treatment

Once hardened, the sprocket is subjected to a variety of surface treatments, such as black oxide, zinc plating, and anodizing. These treatments serve to provide additional protection against corrosion and wear, significantly extending the life of the product.

Quality Inspection

Before packing, the finished sprocket undergoes rigorous quality inspection procedures. Various quality control techniques are employed to ensure that each sprocket meets the highest quality standards, providing peace of mind to our customers regarding the reliability of our products.

Packing and Shipping

After passing quality inspection, the finished sprocket is carefully packed according to customer specifications. We prioritize secure packing to ensure the sprockets are protected during transit, guaranteeing they arrive in perfect condition, ready for installation and use.

Maintenance of Chain Sprockets

Proper maintenance of chain sprockets is vital for ensuring their optimal performance and longevity. Key maintenance tasks include regular inspection, cleaning, lubrication, and timely replacement of worn components.

Daily Inspection

Conducting daily inspections of the sprocket is essential to identify any signs of wear, damage, or misalignment. It is also important to check the tension of the chain regularly and make adjustments as necessary to maintain optimal performance. Regular inspections help in early detection of potential issues, which can prevent more significant problems down the line.

Cleaning

Keeping the sprocket clean is crucial for its longevity. Use a brush and a suitable cleaning solution to remove dirt, debris, and other contaminants that may accumulate over time. A clean sprocket can function more efficiently, as it reduces friction and wear, contributing to the overall effectiveness of the transmission system.

Lubrication

Regular lubrication is key to minimizing friction and wear on the sprocket. Employ high-quality lubricants to ensure even application on both the chain and the sprocket. Proper lubrication not only enhances the performance of the sprocket but also extends its lifespan by reducing the likelihood of premature wear.

Replacement

To maintain optimal performance and prevent further damage, it is vital to replace worn sprockets promptly. A proactive approach to replacement can significantly enhance the reliability of the entire transmission system, ensuring that all components work harmoniously together for efficient operation.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the top ten gear suppliers in Australia. Our extensive range of gear products includes the Plate Wheel Sprocket 05B-1-2, which exemplifies our commitment to quality and performance. As a supplier, we offer a diverse selection of gears that cater to various industrial applications, ensuring that our clients receive the best solutions for their needs.

At GBC, we understand the importance of tailored solutions, which is why we provide non-standard customization based on customer requirements. We are not limited to just standard plate wheel sprockets; we encourage our valued customers to reach out with their specific designs or samples for custom orders. Our dedicated team is here to assist you in finding the perfect gear solutions.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket 05B-1-2 is designed for durability and efficiency, making it an ideal choice for various machinery applications. With its precise engineering and robust construction, this sprocket ensures optimal performance and longevity. GBC proudly offers high-quality Plate Wheel Sprockets in Australia, catering to your industrial needs.