Plate Wheel Sprocket K160A

Plate Wheel Sprocket K160A

The Plate Wheel Sprocket K160A is designed for durability and optimal performance in various industrial applications. Its robust construction ensures longevity, while the precise engineering guarantees smooth operation. This sprocket is an essential component for efficient power transmission in machinery.

GBC proudly offers high-quality Plate Wheel Sprocket K160A in Australia.

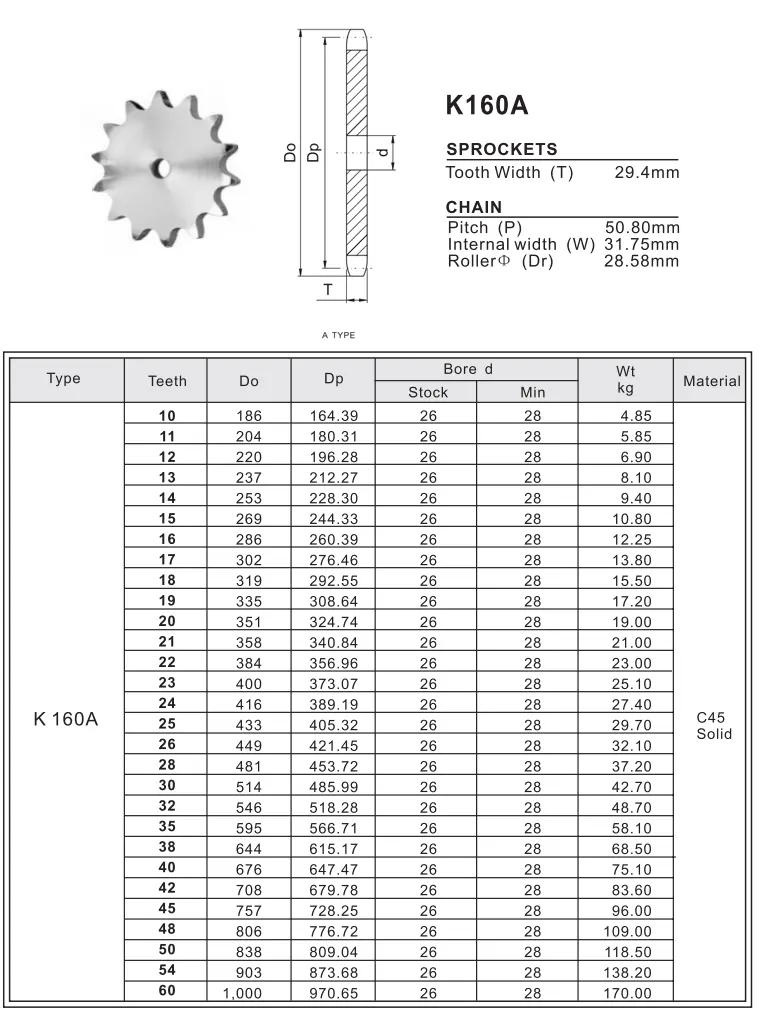

Specifications of Plate Wheel Sprocket K160A

Plate Wheel K160A is an advanced plate chain sprocket widely utilized in various power transmission systems. This vital component effectively transfers power from a driving device to a driven device, ensuring smooth operation in mechanical systems. The construction of the plate wheel involves a series of evenly spaced teeth, which engage seamlessly with the links of a chain, allowing for efficient power transmission under various load conditions.

Types of Plate Wheel Sprockets

Plate wheel sprockets are available in multiple configurations, including single-row, double-row, and multi-row designs. The choice of the plate wheel sprocket is determined by the specific application requirements, which can include factors like load capacity, speed, and the intended environment of use. Each type is engineered to cater to different operational needs, providing flexibility and efficiency in power transmission systems.

Product Features of Our Plate Wheel Sprocket

Our plate wheel sprockets are constructed from high-quality materials that ensure exceptional corrosion resistance, wear resistance, and overall strength. These features guarantee that the sprockets maintain performance even under harsh conditions. They are designed to be lightweight, which aids in reducing the overall load on the driving system. Furthermore, our sprockets undergo a specialized surface treatment that significantly enhances their durability and longevity.

Material Advantages

The materials used in our plate wheel sprockets are selected for their superior properties, including corrosion resistance and high strength. We utilize stainless steel, carbon steel, and alloy steel, each chosen for its unique benefits tailored to meet specific performance criteria. The combination of these materials ensures that the sprockets can withstand wear and extend the service life of the product.

Design Features

Our plate wheel sprockets are meticulously designed to be lightweight while maintaining structural integrity. Precise manufacturing processes are employed to guarantee optimal performance and reliability during operation. The surface treatment they undergo not only bolsters their durability but also makes them suitable for use in demanding environments, such as those with exposure to moisture or chemicals.

Our Services

At GBC - Ever-power Australia Agency, we provide a comprehensive range of services designed to meet the unique needs of our customers. Our offerings include custom design, material selection, surface treatment, hardening treatment, and customized packaging. Our team of experts is dedicated to delivering high-quality products and ensuring customer satisfaction through tailored solutions.

Custom Design

We specialize in designing plate wheel sprockets to accommodate specific customer requirements, such as size, shape, and tooth profile. Our ability to customize designs ensures that our clients receive products that perfectly fit their application needs.

Material Selection

A variety of materials are available for selection, including stainless steel, carbon steel, and alloy steel. This diversity allows us to match the plate wheel sprocket to the intended application, ensuring optimal performance and durability.

Surface Treatment

We offer several surface treatment options, including rust-proofing, which significantly enhances the durability of the plate wheel sprocket. These treatments are crucial in extending the life of the sprocket and maintaining its operational efficiency.

Hardening Treatment

To further enhance the wear resistance and strength of the plate wheel sprocket, we provide hardening treatments. This process is vital for applications involving high stress and frequent use, ensuring that the sprocket performs reliably over time.

Customized Packaging

Our packaging solutions are designed to ensure safe and secure delivery of the plate wheel sprocket to our customers. Customized packaging options are available to meet specific shipping and handling needs, providing additional assurance that products arrive in perfect condition.

Chain Wheel Processing Flow

The production of our plate wheel sprockets follows a rigorous processing flow, which includes several critical stages: forging, machining, hobbing, teeth heating, quenching treatment, surface treatment, quality inspection, and final packaging. Each step in this process is meticulously controlled to ensure the highest quality standards are met.

Forging

The initial stage involves forging the plate wheel sprocket into its basic shape. This step is essential for achieving the desired structural integrity and strength of the final product.

Machining

Following forging, the rough-forged plate wheel sprocket undergoes machining to achieve its final shape. This precision work ensures that all dimensions meet the required specifications for optimal performance.

Hobbing

The teeth of the plate wheel sprocket are carefully hobbed to achieve precise tooth profiles. This process is crucial for ensuring effective engagement with the chain and optimal power transmission.

Teeth Heating

Heating the teeth of the plate wheel sprocket improves their wear resistance significantly. This treatment is essential for ensuring that the sprocket can handle the stresses of operation without premature degradation.

Treated on Quenching

The quenching treatment further enhances the strength of the plate wheel sprocket. This step is vital for increasing its durability and resistance to wear.

Surface Treatment/Rust-Proof Treatment

A thorough surface treatment is applied to improve the durability and corrosion resistance of the plate wheel sprocket. This treatment is particularly important for performance in challenging environments.

Quality Inspection

Each plate wheel sprocket undergoes a stringent quality inspection process to ensure compliance with industry standards and specifications. This step is critical to maintaining our reputation for high-quality products.

Packing and Shipping

Finally, the plate wheel sprocket is carefully packed to ensure safe delivery. We take great care in our packing methods to prevent damage during transportation, providing peace of mind to our customers.

Chain Wheel Maintenance

Regular maintenance is essential for ensuring the optimal performance and longevity of the plate wheel sprocket. This includes daily inspections, thorough cleaning, lubrication, and timely replacements as necessary.

Daily Inspection

Conducting regular inspections of the plate wheel sprocket is vital for identifying any signs of wear or damage early. This proactive approach helps in maintaining operational efficiency and prevents unexpected failures.

Cleaning

To prevent dirt and debris accumulation, the plate wheel sprocket should be cleaned regularly. A clean sprocket operates more efficiently and contributes to the overall performance of the power transmission system.

Lubrication

Regular lubrication of the plate wheel sprocket is essential to ensure smooth and efficient operation. Proper lubrication reduces friction and wear, contributing to a longer service life.

Replacement

If signs of wear or damage are detected that cannot be repaired, immediate replacement of the plate wheel sprocket is crucial. This practice ensures that the power transmission system continues to operate safely and efficiently.

Plate Wheel Sprockets Supplier in Australia

GBC is the sales agent for Ever-power Group in Australia and is recognized as one of the top ten gear suppliers in the region. Our extensive range of gear products includes the Plate Wheel Sprocket K160A, which exemplifies our commitment to quality and performance.

As a supplier, we pride ourselves on the diversity of our gear offerings, catering to various industries and applications. Our products are designed to meet the specific needs of our customers, ensuring optimal functionality and durability. In addition to standard offerings, our team is dedicated to providing exceptional service, assisting clients in selecting the right products for their requirements.

We understand that each customer's needs may vary, which is why we also offer non-standard customization based on client requests. We are not limited to just standard plate wheel sprockets; we welcome customers to bring their designs and samples for tailored solutions. Your satisfaction is our priority.

Additional information

| Edited by | Sylvia |

|---|

Plate Wheel Sprocket K160A

The Plate Wheel Sprocket K160A is designed for durability and optimal performance in various industrial applications. Its robust construction ensures longevity, while the precise engineering guarantees smooth operation. This sprocket is an essential component for efficient power transmission in machinery.

GBC proudly offers high-quality Plate Wheel Sprocket K160A in Australia.