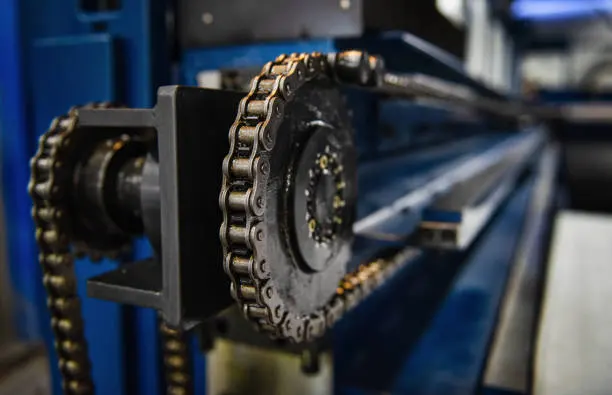

The drive chain is a common power transmission component in mechanical equipment and is widely used in bicycles, motorcycles, industrial machinery, and other fields. However, as the use time increases, the drive chain will inevitably wear out, affecting its performance and life.

Insufficient Lubrication

Lubrication is one of the key factors in keeping the drive chain running properly. If the chain lacks sufficient lubrication, the friction between the metal surfaces will increase, resulting in increased wear.

Improper Lubricant Selection

The use of unsuitable lubricants may not effectively reduce friction and may even attract dust and impurities, further accelerating wear.

Insufficient Lubrication Frequency

Long-term non-lubrication or long lubrication intervals will cause the chain surface to dry and increase the risk of wear.

Excessive Load

When the drive chain works under excessive load, it will be subjected to additional stress, resulting in accelerated wear of the chain and sprocket.

Overload Operation

When the equipment operates beyond the design load, the chain will be subjected to excessive tension and accelerated wear.

Shock Loads

Frequent shock loads or sudden load changes can also cause additional wear on the chain.

Environmental Factors

The working environment also has a significant impact on the wear of the drive chain, especially under harsh conditions.

Dust and Impurities

Impurities such as dust and sand enter the chain, which increases friction and causes wear.

Moisture and Corrosion

In a humid or corrosive environment, the chain is prone to rust, which accelerates wear.

Improper Installation and Maintenance

Improper installation and lack of maintenance can also cause wear on the drive chain.

Chain Is Too Tight or Too Loose

Installing the chain too tight will increase the friction between the chain and the sprocket, while too loose may cause the chain to jump and increase wear.

Failure to Check Regularly

Failure to check the wear of the chain regularly may cause small problems to accumulate into big problems, and eventually accelerate wear.

Material and Quality Issues

The material and quality of the chain directly affect its wear resistance and service life.

Improper Material Selection

Low-quality materials or materials that do not meet the use environment will reduce the wear resistance of the chain.

Manufacturing Defects

Defects in the manufacturing process, such as improper heat treatment or poor surface treatment, can also cause premature chain wear.

There are many reasons for transmission chain wear. By understanding the above common reasons, you can take corresponding preventive measures, such as regular lubrication, reasonable load, improved working environment, correct installation and regular inspection, so as to extend the service life of the transmission chain and improve the operating efficiency of the equipment.