Crane Spring Cylinder

Crane spring cylinders have the function of preventing backward tilt, cushioning and stabilizing the output force, and preventing the piston rod from falling during operation. These features not only enhance the safety of the equipment, but also optimize its performance and responsiveness, which is an important part of guaranteeing the stable operation of cranes.

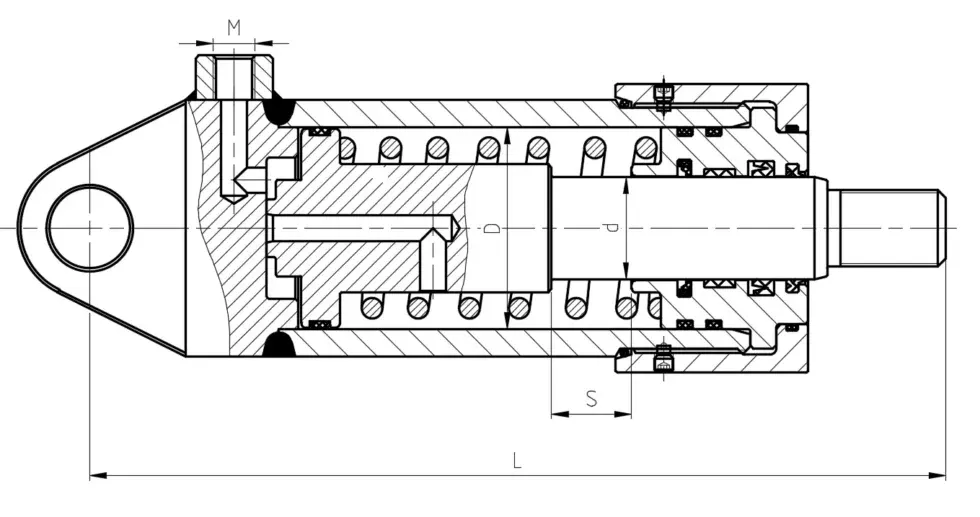

Crane Spring Cylinder Technical Specification

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Spring cylinder | ZXYG24.01-00 | Φ63 | Φ32 | 25 | 267 | 4MPa | G1/4 | 6.5kg |

Main Functions of Crane Spring Cylinders

Anti-backward tilt function

In crawler cranes, spring cylinders are commonly used in anti-backward tilt devices. For example, in the tower jib condition, in order to prevent the jib from tilting back due to the large elevation angle of the tower jib, the anti-tilting device is usually installed at the root of the tower jib front spar. Through its elastic potential energy, the oil and gas spring cylinder can provide the necessary support force when the jib is tilted back, so as to prevent the phenomenon of tilting back.

Cushioning and stabilizing output force

Adding springs to the cylinder improves the output performance of the cylinder. The spring plays the role of a buffer in the work of the cylinder, reducing the sudden change of pressure in the oil pipe and stabilizing the output force of the cylinder. In addition, springs improve the response speed of the cylinder. When hydraulic pressure is input, the spring will be stressed first and then the force will be gradually transferred to the cylinder, thus improving the response speed.

Prevent the piston rod from falling

In the tire-type hydraulic gantry crane, the jacking cylinder is fixed with a spring top bead. This design prevents the piston rod from falling by locking the cylinder when the piston rod is retracted; and when the piston rod is extended, the top bead will be disengaged, allowing the cylinder to jack up the crane. This design helps to prevent the piston rod falling accident and ensure the safe operation of the crane.

Crane Hydraulic Cylinders Manufacturer

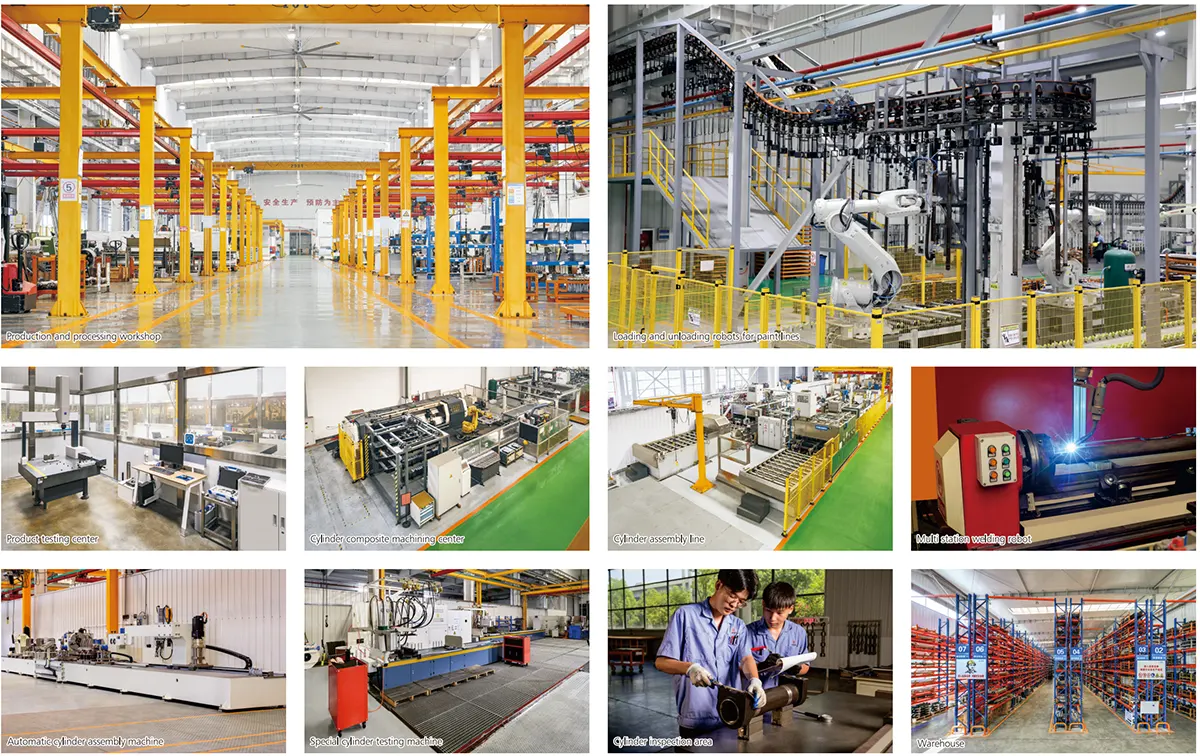

GBC is the Australian sales agent for Ever-power Group, a leading manufacturer in hydraulic technology. Our company specializes in producing high-quality crane spring cylinders that meet the rigorous demands of the industry. With a commitment to excellence, we leverage advanced manufacturing processes and stringent quality control measures to ensure that our products are reliable and efficient.

Our strength lies not only in our robust product offerings but also in our exceptional customer service. We take pride in understanding our clients' needs and delivering solutions that enhance their operations. In addition to our standard trailer cylinders, we offer customized hydraulic cylinders tailored to meet specific requirements. For cylinders with a diameter of D360MM and a stroke of L6000MM, we encourage our clients to provide their designs or samples for non-standard customization. We welcome inquiries and look forward to collaborating with you on your unique projects.

Additional information

| Edited by | Sylvia |

|---|

Crane spring cylinders have the function of preventing backward tilt, cushioning and stabilizing the output force, and preventing the piston rod from falling during operation. These features not only enhance the safety of the equipment, but also optimize its performance and responsiveness, which is an important part of guaranteeing the stable operation of cranes.

Crane Hydraulic Cylinders Reviews

Mark Johnson – Procurement Manager

e Crane Spring Cylinder we purchased has exceeded our expectations. The build quality is excellent, and the durability ensures stable performance under heavy loads. Our crane operations have become smoother, with improved shock absorption. The delivery was on time, and the customer support was very responsive. Highly recommended!