Crane Counterweight Hydraulic Cylinder

The counterweight cylinder of the crane is an important part of the crane, which is mainly used for balancing and stabilizing the crane to ensure safe operation. The counterweight cylinder changes its own weight by adjusting the pressure of the internal oil, thus realizing the balance and stabilization of the crane. During crane operation, the counterweight cylinder can effectively offset the moment generated by the lifting object, preventing the crane from tipping over or overturning and other accidents..

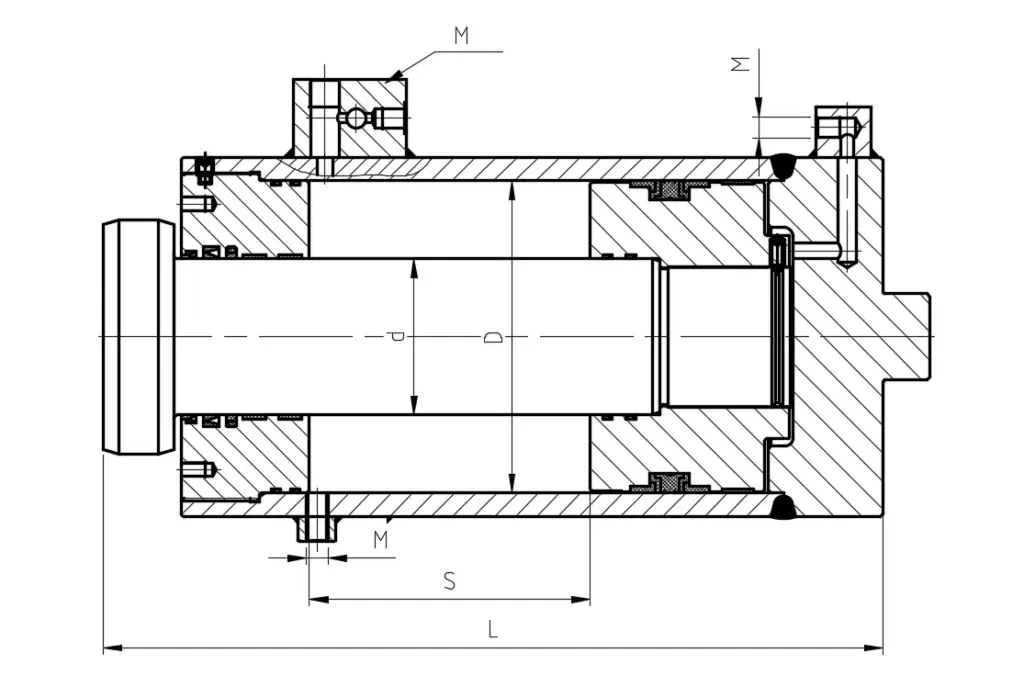

Crane Counterweight Hydraulic Cylinder Technical Specification

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Counterweight hydraulic cylinder | QAY220.12/13A-00 | Φ200 | Φ100 | 180 | 530 | 25MPa;40MPa | 3-G1/4;M20*1.5;2-M14*1.5 | 124kg |

| Item | Description |

| Product Name | Custom-made hydraulic Cylinder |

| Certificate: | ISO9001, ISO4001, ISO 45003 |

| Production Capacity: | 1200,000 pcs per year |

| Sample Time | Based actual type |

| Brand | EPT or customer's logo |

| Service | OEM & ODM |

| Seal brand | Parker,NOK, BUSAK SHAMBAN |

| Delivery Time | Based on order quantity. |

| Business Type | Manufacturer & Exporter |

Main Functions of Crane Counterweight Cylinder

Balance the center of gravity: Hydraulically control the movement of the counterweight block to prevent the crane from tipping over due to center of gravity shift.

Improve stability: In complex terrain or high load conditions, the counterweight cylinder can dynamically adjust the counterweight to enhance the stability of the equipment.

Flexibility: Allows the crane to adapt quickly to different working conditions and achieve the best performance by adjusting the counterweight.

Crane Counterweight Hydraulic Cylinder Technical Features

High Strength Material: Cylinders are usually manufactured with wear-resistant and high-strength materials to cope with high pressure and frequent use.

Precise control: Equipped with an advanced hydraulic control system that enables precise positioning of the counterweight.

Weather Resistance: Designed to withstand extreme temperatures and harsh environments to ensure long term reliable operation.

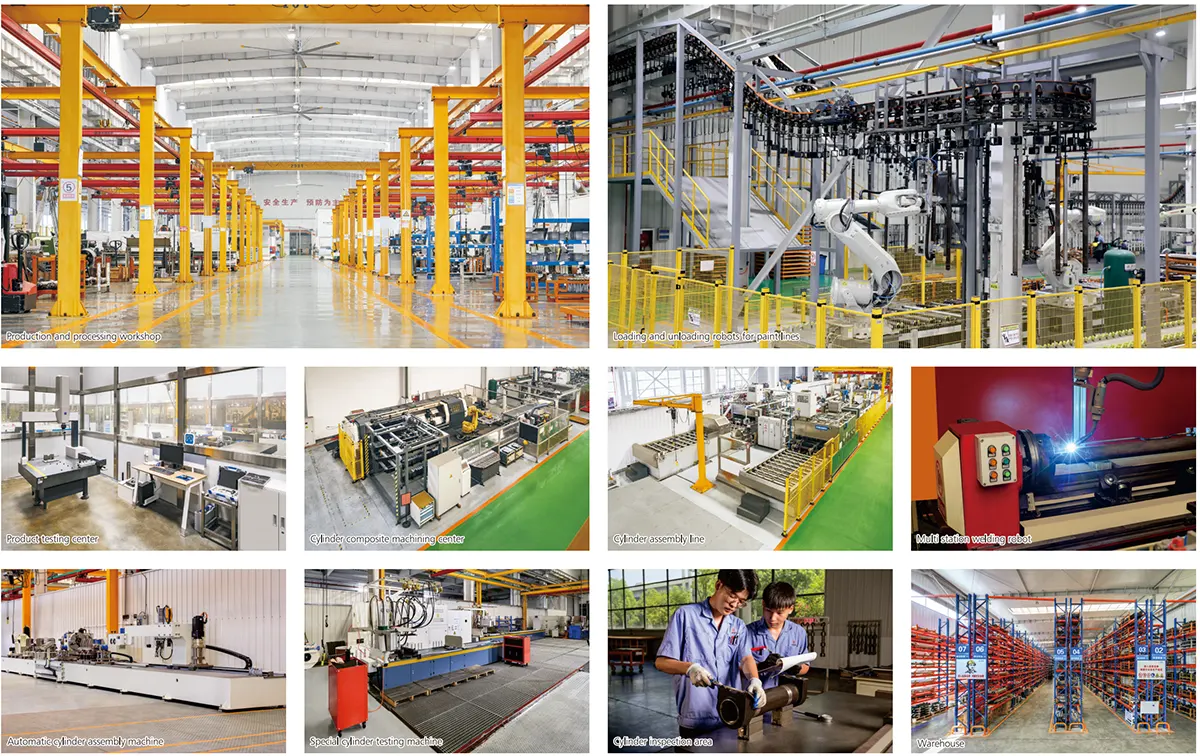

Crane Hydraulic Cylinders Manufacturer

GBC is the Australian sales agent for Ever-power Group, a leading manufacturer known for its high-quality hydraulic solutions. Our company takes pride in our expertise in producing Crane Counterweight Hydraulic Cylinders, which are designed to deliver exceptional performance even under the most demanding conditions. We understand the importance of reliability and durability in hydraulic systems, and our products reflect our commitment to excellence.

In addition to our standard offerings, we specialize in custom hydraulic cylinders tailored to meet specific customer requirements. We can manufacture non-standard cylinders with a diameter of D360MM and a stroke length of L6000MM, providing flexibility to accommodate unique applications. We invite all customers to collaborate with us by providing drawings and samples for custom designs. Our dedicated team is ready to assist you in achieving your project's specific needs, ensuring you receive the precise hydraulic solution you envision.

Additional information

| Edited by | Sylvia |

|---|

The counterweight cylinder of the crane is an important part of the crane, which is mainly used for balancing and stabilizing the crane to ensure safe operation. The counterweight cylinder changes its own weight by adjusting the pressure of the internal oil, thus realizing the balance and stabilization of the crane. During crane operation, the counterweight cylinder can effectively offset the moment generated by the lifting object, preventing the crane from tipping over or overturning and other accidents..

Crane Hydraulic Cylinders Reviews

Matthew Turner – Maintenance Supervisor

We’ve been using this Crane Counterweight Hydraulic Cylinder for months, and it has exceeded our expectations. It effectively stabilizes the crane, reducing structural stress and enhancing overall safety. The cylinder is well-manufactured, with excellent sealing to prevent leaks. Installation was easy, and the supplier was very professional throughout the process. A great investment for any crane operation!