06B-1 European Standard Finished Bore Sprocket

The 06B-1 European Standard Finished Bore Sprocket is designed for optimal performance in various mechanical applications. Engineered with precision, this sprocket ensures reliable power transmission and longevity, making it an essential component in machinery and conveyor systems. Its finished bore design allows for easy installation and compatibility with different shafts. Crafted from high-quality materials, the 06B-1 sprocket significantly reduces wear and enhances efficiency. GBC proudly offers this premium product in Australia, meeting the industry’s highest standards.

Introduction

A finished bore sprocket is a crucial part utilized in a range of industrial applications. It is designed to transmit rotary motion between two shafts through a roller chain. The 06B-1 European Standard specifies the size and dimensions of the sprocket, ensuring it works seamlessly with the corresponding roller chains.

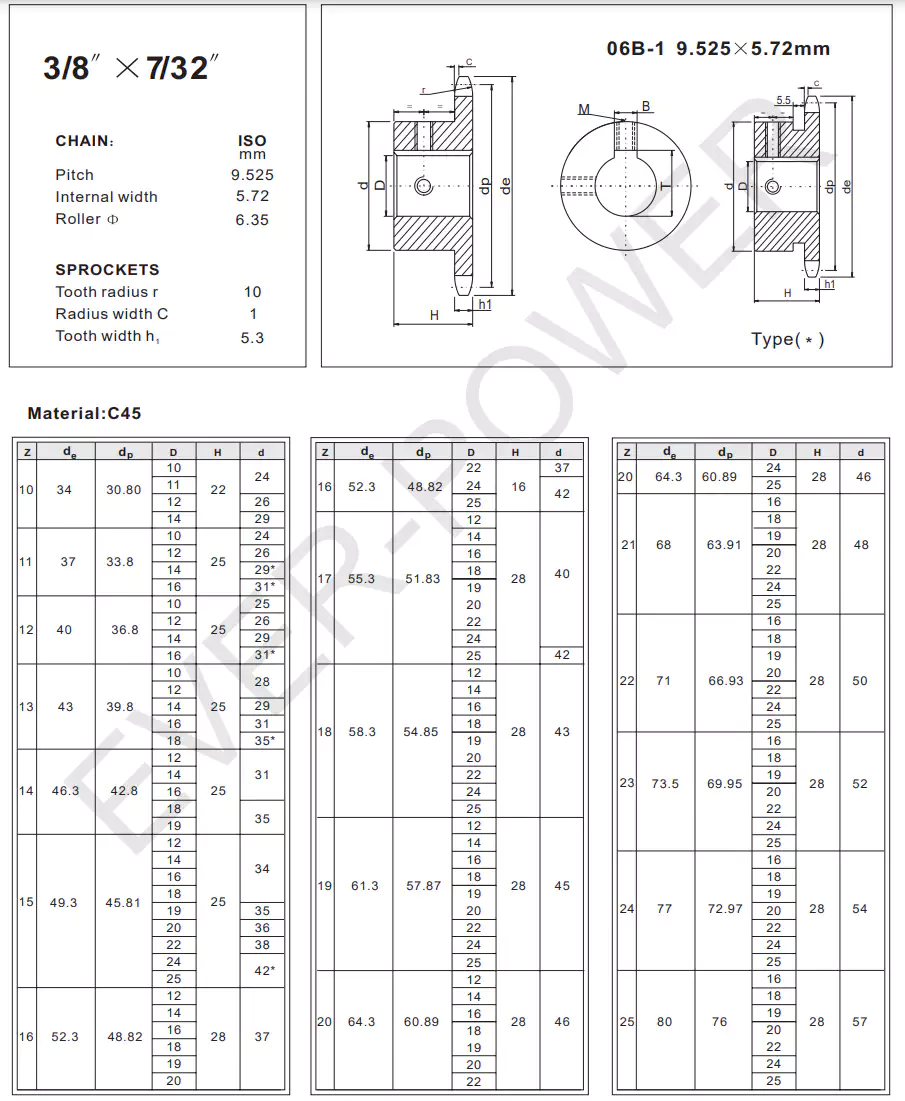

Specifications of 06B-1 European Standard Finished Bore Sprocket

Materials and Manufacturing Process

The finished bore sprockets provided are crafted from high-quality materials such as high carbon steel, alloy steel, or stainless steel. The selection of material is based on the application’s specific needs. The manufacturing process includes material selection, cutting, stamping, forging, machining (turning, milling, drilling), heat treatment (quenching, tempering, surface hardening), surface treatment (rust prevention), and quality testing. Each step is meticulously carried out to guarantee the sprocket's durability and performance.

Applications

Finished bore sprockets are utilized in various industries, including:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical

- Assembly lines

- Logistics and warehousing

Maintenance and Care

To maintain optimal performance and longevity of the sprocket, regular maintenance and care are vital. Consider the following points:

- Daily inspections for signs of damage or wear

- Cleaning to eliminate dirt, debris, and contaminants

- Lubrication to minimize friction and prevent corrosion

- Adjustments and calibration to keep proper tension and alignment

Common issues that may occur with sprockets include tooth skipping, breakage, wear, excessive noise, and chain derailment. To resolve these problems:

- Tooth skipping can be rectified by checking proper chain engagement and tension.

- Breakage may necessitate replacing the sprocket and ensuring the chain is well-aligned.

- Wear can be reduced through consistent lubrication and replacing worn components.

- Excessive noise may indicate misalignment or worn parts, which should be addressed quickly.

- Chain derailment can be avoided by maintaining proper tension and alignment.

Other Sprocket Options

Besides the finished bore sprocket 06B-1 European Standard, GBC - Ever-power Australia Agency also offers other types of sprockets such as taper lock sprockets, qd sprockets, idler sprockets, and various models of roller chains.

Sprockets Supplier in Australia

GBC is the sales agent for Ever-power Group in Australia, providing high-quality industrial components to meet the needs of various sectors. Our product range includes the 06B-1 European Standard Finished Bore Sprocket, known for its durability and precision. These sprockets are designed to work efficiently with roller chains, ensuring smooth and reliable operation in your machinery.

In addition to our standard sprockets, we also offer non-standard customization services to meet specific customer requirements. We encourage all customers to bring their drawings or samples for tailored solutions. Our dedicated team is ready to assist you in finding the perfect sprocket in Australia for your applications.

Additional information

| Edited by | Sylvia |

|---|

The 06B-1 European Standard Finished Bore Sprocket is designed for optimal performance in various mechanical applications. Engineered with precision, this sprocket ensures reliable power transmission and longevity, making it an essential component in machinery and conveyor systems. Its finished bore design allows for easy installation and compatibility with different shafts. Crafted from high-quality materials, the 06B-1 sprocket significantly reduces wear and enhances efficiency. GBC proudly offers this premium product in Australia, meeting the industry’s highest standards.