40BS*HT American Standard Finished Bore Sprocket

The 40BS*HT American Standard Finished Bore Sprocket is designed for durability and precision in various mechanical applications. Crafted with high-quality materials, it ensures optimal performance and longevity, making it ideal for heavy-duty tasks. This sprocket features a finished bore, allowing for easy installation and a secure fit on your machinery. With its robust design, it can withstand demanding operational conditions while delivering consistent power transmission. GBC proudly offers this product in Australia, ensuring reliable supply and exceptional service.

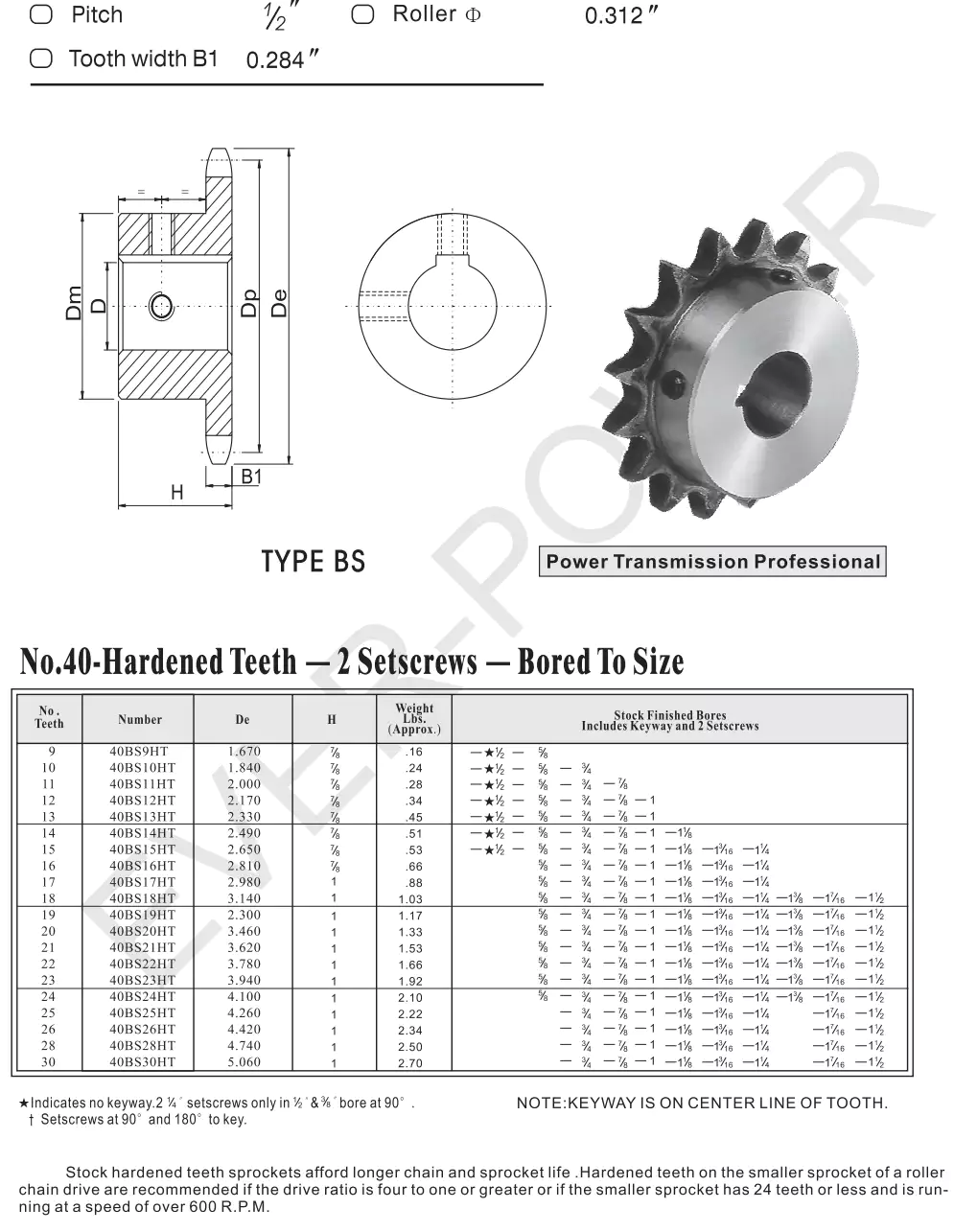

Specifications of 40BS*HT American Standard Finished Bore Sprocket

A finished bore sprocket is designed to fit onto a specific shaft size without the need for additional machining. It is a vital component in power transmission systems, facilitating the transmission of rotary motion between two shafts.

Materials and Manufacturing Process

The finished bore sprockets are produced from high carbon steel, alloy steel, or stainless steel. The manufacturing process includes several stages: material selection, cutting, punching, forging, machining, heat treatment, surface hardening, surface treatment, and quality inspection.

- Material selection: The appropriate material is chosen based on the specific application requirements.

- Cutting, punching, and forging: The selected material undergoes cutting, punching, and forging to achieve the desired shape and size.

- Machining: The sprocket is machined to meet the required dimensions and tolerances.

- Heat treatment: This process enhances the hardness and strength of the sprocket.

- Surface hardening: The sprocket's teeth and bore are hardened to increase wear resistance.

- Surface treatment: Treatment is applied to prevent rust and corrosion.

- Quality inspection: The finished sprocket is inspected to ensure it meets required specifications.

Applications of Plate Wheel Sprockets

Plate wheel sprockets are widely used across various sectors, including heavy machinery, food processing and packaging, chemical and pharmaceutical industries, assembly lines, as well as logistics and warehousing.

Maintenance and Common Issues

To prolong the lifespan of a plate wheel sprocket and prevent issues like tooth jumping, breakage, wear, excessive noise, and chain slipping, proper maintenance is essential. Regular inspection, cleaning, lubrication, adjustment, and calibration are crucial for maintaining the sprocket's condition.

- Regular inspection: Regularly check the sprocket for signs of wear, damage, or misalignment.

- Cleaning: Periodically clean the sprocket and chain to eliminate dirt, debris, and contaminants.

- Lubrication: Lubricate the sprocket teeth and chain to minimize friction and wear.

- Adjustment: Adjust the tension and alignment of the chain and sprocket as necessary.

- Calibration: Utilize a chain wear gauge to assess chain stretch and replace it when needed.

When common issues arise, specific solutions can be implemented. For tooth jumping, ensure proper chain tension and alignment, making adjustments as required. In case of breakage, inspect the sprocket for damage or wear and replace it if necessary. For wear, replace both the chain and sprocket when they exceed the manufacturer's wear limits. If excessive noise occurs, check for worn or damaged teeth and replace the sprocket if needed. To resolve chain slipping, verify proper chain tension and alignment, adjusting as necessary.

Other Products

Besides finished bore sprockets, GBC - Ever-power Australia Agency also provides other sprocket types such as taper lock sprockets, QD sprockets, idler sprockets, and various chain types.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, providing high-quality sprockets and related products to meet the needs of various industries. Our flagship product, the 40BS*HT American Standard Finished Bore Sprocket, showcases our commitment to excellence and durability. Designed for optimal performance, this sprocket ensures seamless operation in your machinery, enhancing efficiency and reliability.

In addition to standard sprockets, we offer customized solutions tailored to our clients' specific requirements. We invite customers to bring their designs or samples for bespoke sprocket manufacturing, ensuring that every product perfectly fits your unique needs. Our team is dedicated to delivering exceptional service and quality, making us your trusted partner in sprocket supply.

Additional information

| Edited by | Sylvia |

|---|

The 40BS*HT American Standard Finished Bore Sprocket is designed for durability and precision in various mechanical applications. Crafted with high-quality materials, it ensures optimal performance and longevity, making it ideal for heavy-duty tasks. This sprocket features a finished bore, allowing for easy installation and a secure fit on your machinery. With its robust design, it can withstand demanding operational conditions while delivering consistent power transmission. GBC proudly offers this product in Australia, ensuring reliable supply and exceptional service.