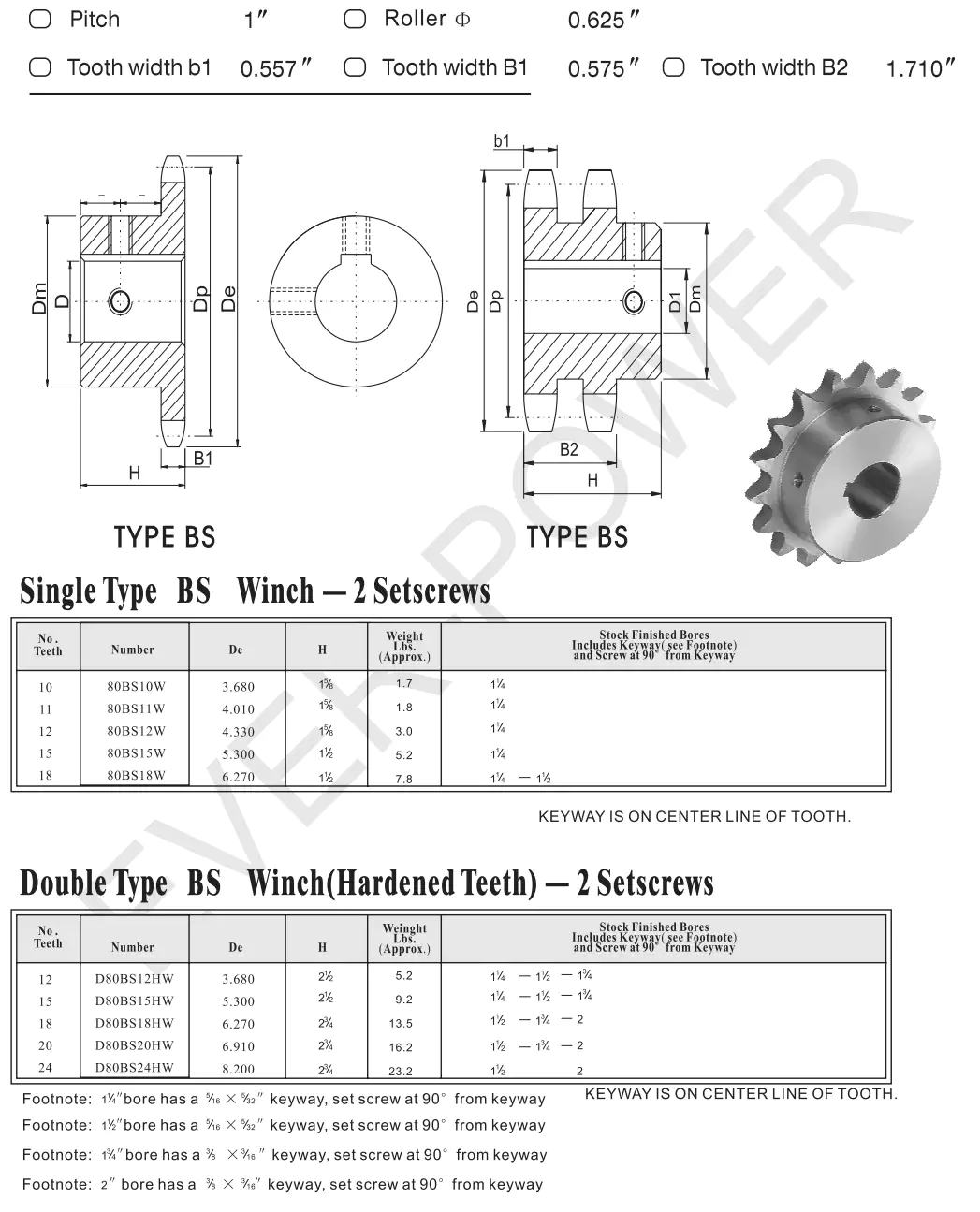

D80BS*HW American Standard Finished Bore Sprocket

The D80BS*HW American Standard Finished Bore Sprocket is engineered for optimal performance and durability in various industrial applications. Constructed from high-quality materials, this sprocket ensures a precise fit and reliable operation, making it ideal for heavy-duty machinery and conveyor systems. With its finished bore design, installation is straightforward, reducing downtime and enhancing productivity. Trust in the D80BS*HW to deliver consistent results in demanding environments.

GBC proudly offers this product in Australia, providing top-notch solutions for your industrial needs.

Specifications of D80BS*HW American Standard Finished Bore Sprocket

A finished bore sprocket is a type of sprocket that has a pre-bored hole, allowing it to be easily mounted onto a shaft without additional machining. It is commonly utilized in various mechanical systems for power transmission and motion control purposes.

Materials and Processes

Our finished bore sprockets are manufactured from high carbon steel, alloy steel, or stainless steel. These materials are selected for their strength, durability, and resistance to corrosion. The manufacturing process includes material selection, cutting, stamping, forging, machining (turning, milling, drilling), heat treatment (quenching, tempering, surface hardening), surface treatment (rust prevention), and quality inspection.

Applications

Finished bore sprockets are widely used across various industries and applications, including:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical

- Assembly lines

- Logistics and warehousing

Maintenance and Care

To ensure optimal performance and longevity of a chain sprocket, regular maintenance and care are essential. The following points should be considered:

- Daily inspections: Check for any signs of wear, damage, or misalignment.

- Cleaning: Remove dirt, debris, and lubricant buildup using appropriate cleaning methods.

- Lubrication: Apply lubricant to reduce friction and wear between the chain and sprocket.

- Adjustment and calibration: Ensure proper tension and alignment of the chain for smooth operation.

Common issues that may arise with chain sprockets include tooth skipping, breakage, wear, excessive noise, and chain disengagement. To address these problems, the following solutions can be implemented:

- Tooth skipping: Check for misalignment, worn teeth, or insufficient tension. Adjust or replace the sprocket as needed.

- Breakage: Examine the sprocket for cracks or fractures. Replace the sprocket if necessary.

- Wear: Measure the sprocket's tooth profile and compare it to the manufacturer's specifications. Replace if worn beyond acceptable limits.

- Excessive noise: Ensure proper lubrication and alignment. Replace the sprocket if noise persists.

- Chain disengagement: Inspect the chain for damage or elongation. Adjust or replace the chain as required.

In addition to finished bore sprockets, we also offer various types of sprockets such as taper lock sprockets, qd sprockets, idler sprockets, and multiple types and models of chains.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, specializing in high-quality sprockets and related products. One of our featured products is the D80BS*HW American Standard Finished Bore Sprocket, which is designed to meet rigorous standards and deliver reliable performance in various applications. Our sprockets are crafted from durable materials, ensuring longevity and efficiency in machinery operations.

In addition to our standard sprockets, we offer non-standard customization services to meet specific customer requirements. We encourage customers to provide their designs or samples for tailored solutions. Your satisfaction is our priority, and we look forward to fulfilling your unique needs.

Additional information

| Edited by | Sylvia |

|---|

The D80BS*HW American Standard Finished Bore Sprocket is engineered for optimal performance and durability in various industrial applications. Constructed from high-quality materials, this sprocket ensures a precise fit and reliable operation, making it ideal for heavy-duty machinery and conveyor systems. With its finished bore design, installation is straightforward, reducing downtime and enhancing productivity. Trust in the D80BS*HW to deliver consistent results in demanding environments.

GBC proudly offers this product in Australia, providing top-notch solutions for your industrial needs.