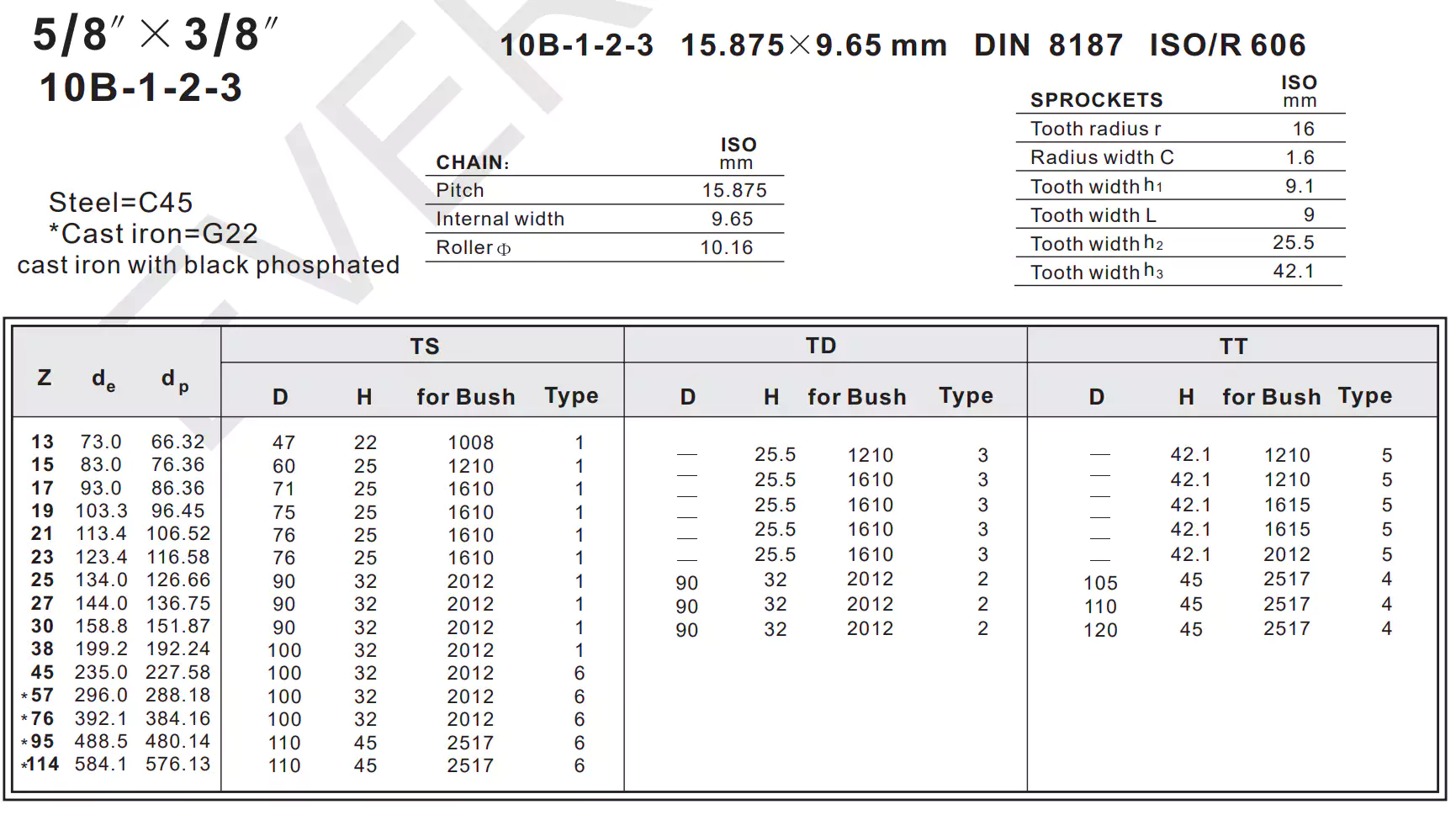

10B-1-2-3 5/8" Taper Bore Sprocket - Specifications

The 10B-1-2-3 5/8" Taper Bore Sprocket is widely utilized in transmission systems. It features a taper lock design that facilitates straightforward installation and removal. This sprocket is employed across various applications for power and motion transmission.

Definition and Basic Structure

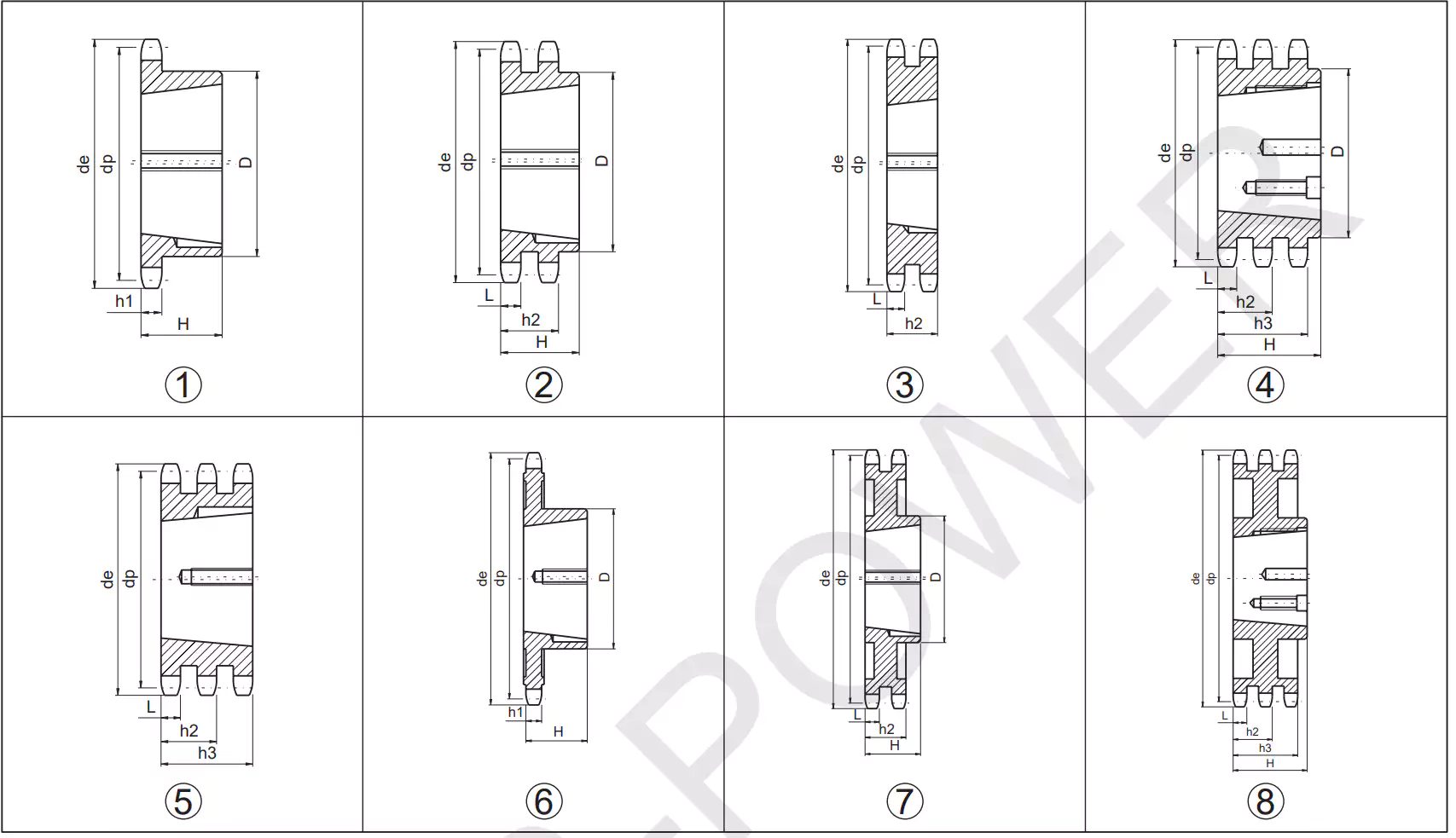

Taper lock sprockets feature a tapered bore designed for mounting on a shaft using a taper lock bushing. The fundamental structure includes teeth that engage with a chain or belt, a hub with a tapered bore, and a taper lock bushing that ensures a secure and precise fit on the shaft.

Characteristics and Functions

- Easy Installation: The taper lock design simplifies installation, enabling quick and hassle-free mounting on the shaft.

- High Precision Positioning: The taper lock bushing ensures a precise fit on the shaft, leading to accurate sprocket positioning.

- Wide Applicability: These sprockets are versatile and suitable for a variety of applications across different industries.

- Reliability: The secure fit and robust construction of taper lock sprockets provide high reliability in power and motion transmission.

- Low Maintenance Cost: Minimal maintenance requirements contribute to long-term cost savings.

Installation and Removal Process

- Prepare Tools and Materials: Gather necessary tools and materials for installation, including the taper lock bushing, sprocket, and locking nut.

- Clean Shaft and Sprocket Surface: Ensure both the shaft and sprocket surface are clean and free from debris.

- Place Taper Lock Bushing: Slide the taper lock bushing onto the shaft, ensuring proper alignment.

- Install Sprocket: Position the sprocket onto the taper lock bushing, ensuring that the teeth mesh with the chain or belt.

- Tighten Locking Nut: Securely tighten the locking nut to fix the sprocket in place.

Manufacturing Process

The manufacturing process of taper lock sprockets involves several steps:

- Raw Material Preparation: Choose and prepare suitable raw materials such as steel or cast iron.

- Cutting: Cut the raw material into the desired shape and size.

- Forging or Casting: Create the sprocket's basic structure using forging or casting methods.

- Machining: Refine the sprocket's shape and dimensions through machining techniques.

- Tooth Rolling: Form the sprocket teeth using a rolling process.

- Heat Treatment: Enhance the sprocket's hardness and strength through heat treatment.

- Surface Treatment: Apply surface treatments such as coating or plating to improve corrosion resistance.

- Quality Inspection: Conduct thorough quality inspections to ensure compliance with required standards.

Sprockets Supplier in Australia

GBC is the sales agent for Ever-power Group in Australia, providing top-quality sprockets and related products to meet the needs of various industries. Among our extensive product range, we offer the 10B-1-2-3 5/8" Taper Bore Sprocket, which is designed for durability and efficiency in power transmission applications. Our sprockets are manufactured using high-grade materials and advanced technology to ensure longevity and optimal performance.

In addition to standard sprockets, our company specializes in non-standard customizations tailored to our clients' specific requirements. We welcome customers to bring their designs and samples for custom orders, ensuring that every sprocket perfectly fits their unique applications.

Additional information

| Edited by | Sylvia |

|---|