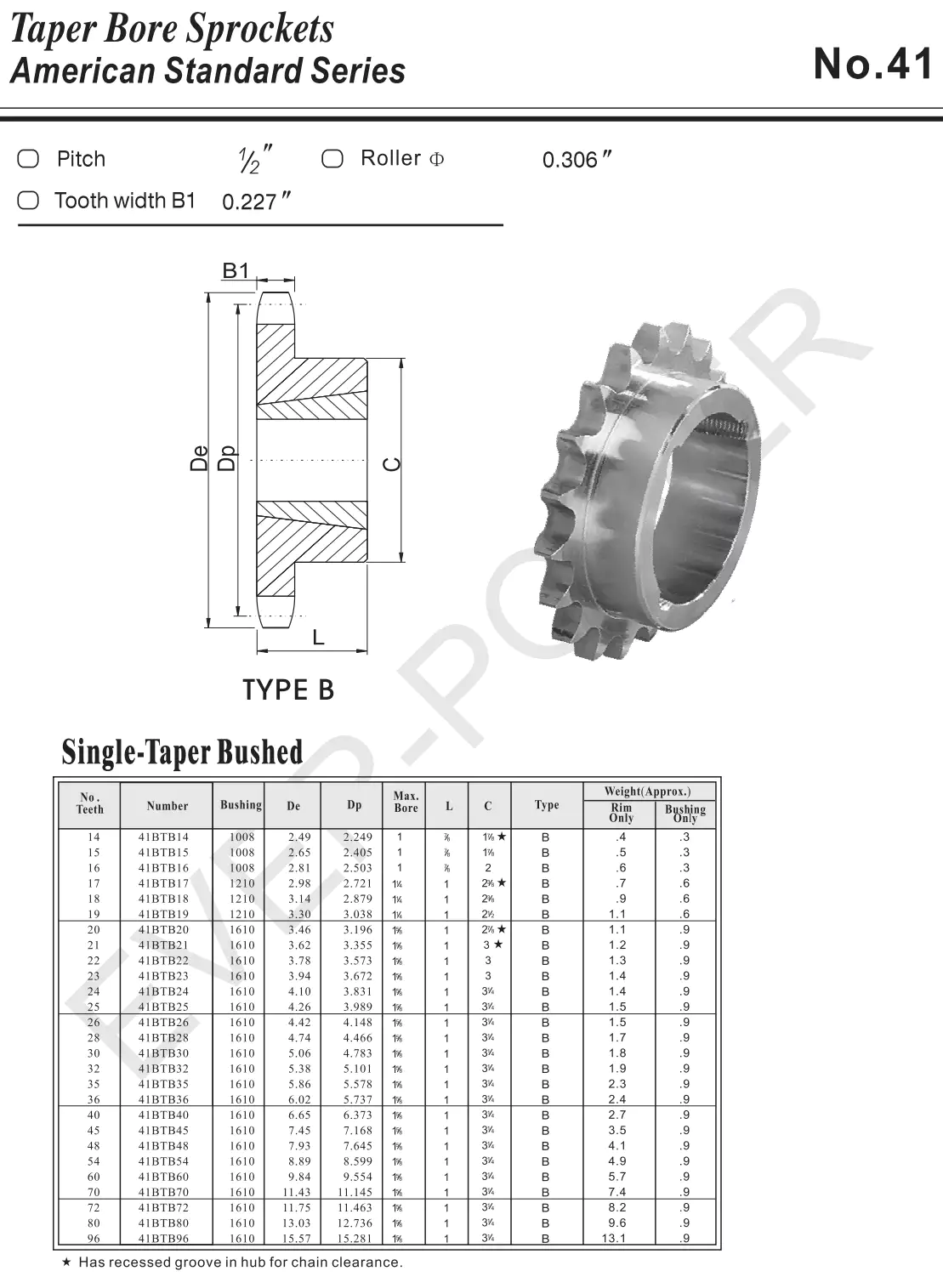

#41 1/2" Taper Lock Sprocket Specifications

#41 1/2" Taper Lock Sprocket is a type of sprocket utilized in power transmission systems. It features a tapered bore and a hub that allows for easy mounting on a shaft without requiring a keyway. This sprocket facilitates the transmission of motion and power between shafts and is commonly employed in conveyor systems, agricultural machinery, and industrial equipment.

Definition and Basic Structure of Taper Lock Sprocket

A Taper Lock Sprocket is specifically designed with a tapered bore and a hub, enabling easy installation on a shaft without a keyway. It is secured in place using a locking bush. The fundamental structure of a Taper Lock Sprocket comprises a hub, teeth, and a bore. The teeth engage with the chain, while the bore allows for mounting on the shaft.

Characteristics and Functions of Taper Lock Sprocket

- Easy to Install: The tapered bore design facilitates straightforward installation without requiring a keyway, making the sprocket easy to install and remove from the shaft.

- High Precision Positioning: Taper Lock Sprockets provide high precision positioning, ensuring accurate power and motion transmission.

- Wide Applicability: These sprockets are extensively used in conveyor systems, agricultural machinery, and industrial equipment due to their versatility.

- Reliability: Known for their reliability, Taper Lock Sprockets are a favored choice in power transmission systems.

- Low Maintenance Cost: They require minimal maintenance, leading to reduced costs over time.

The ease of installation and removal of the Taper Lock Sprocket is a significant advantage, minimizing downtime and allowing for prompt maintenance. Its precision positioning guarantees accurate transmission of power and motion, while its broad applicability marks it as a versatile option for various uses. The reliability and low maintenance cost contribute to its popularity in power transmission systems.

Installation and Removal Process of Taper Lock Sprocket

The process to install and remove a Taper Lock Sprocket involves several steps:

- Prepare Tools and Materials: Gather necessary tools and materials, including the Taper Lock Bushing, the sprocket, and a torque wrench.

- Clean Shaft and Sprocket Surface: Clean the shaft and sprocket surfaces to eliminate dirt or debris that could impact installation.

- Place Taper Lock Bushing: Position the Taper Lock Bushing onto the shaft and align it with the sprocket bore.

- Install Sprocket: Carefully slide the sprocket onto the bushing until it is flush against the shoulder.

- Tighten Locking Nut: Using a torque wrench, tighten the locking nut to the specified torque value.

By following these steps, you can ensure that the Taper Lock Sprocket is installed correctly and securely. Adhering to the manufacturer's instructions and torque specifications is crucial for proper installation.

Manufacturing Process of Taper Lock Sprocket

The manufacturing process of a Taper Lock Sprocket includes several key steps:

- Prepare Raw Materials: Gather raw materials, typically steel or other metals.

- Cut Material: Cut the material to the required size and shape.

- Forge or Cast: Forge or cast the material into the desired shape, depending on the chosen manufacturing process.

- Machine Teeth: Machine the teeth of the sprocket using cutting tools.

- Heat Treatment: Heat treat the sprocket to enhance its hardness and durability.

- Surface Treatment: Apply a surface treatment, such as plating or coating, to improve corrosion resistance.

- Quality Inspection: Inspect the sprocket to ensure it meets quality standards.

Adhering to these steps guarantees that the Taper Lock Sprocket is manufactured to meet the required standards and specifications. Each step is meticulously monitored to ensure compliance with quality standards.

By understanding the fundamentals of the #41 1/2" Taper Lock Sprocket, its characteristics and functions, as well as the installation and removal process, you can ensure the efficient and effective operation of your power transmission system.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, specializing in high-quality sprockets and related products. Among our diverse offerings, the #41 1/2" Taper Lock Sprocket stands out for its durability and precision engineering, making it an ideal choice for various industrial applications. Our products are designed to meet the rigorous demands of different sectors, ensuring optimal performance and longevity.

In addition to standard sprockets, we also provide customized solutions tailored to our customers' specific needs. We welcome clients to bring their designs or samples for non-standard customization, ensuring that your unique requirements are met with the utmost attention to detail.

Additional information

| Edited by | Sylvia |

|---|