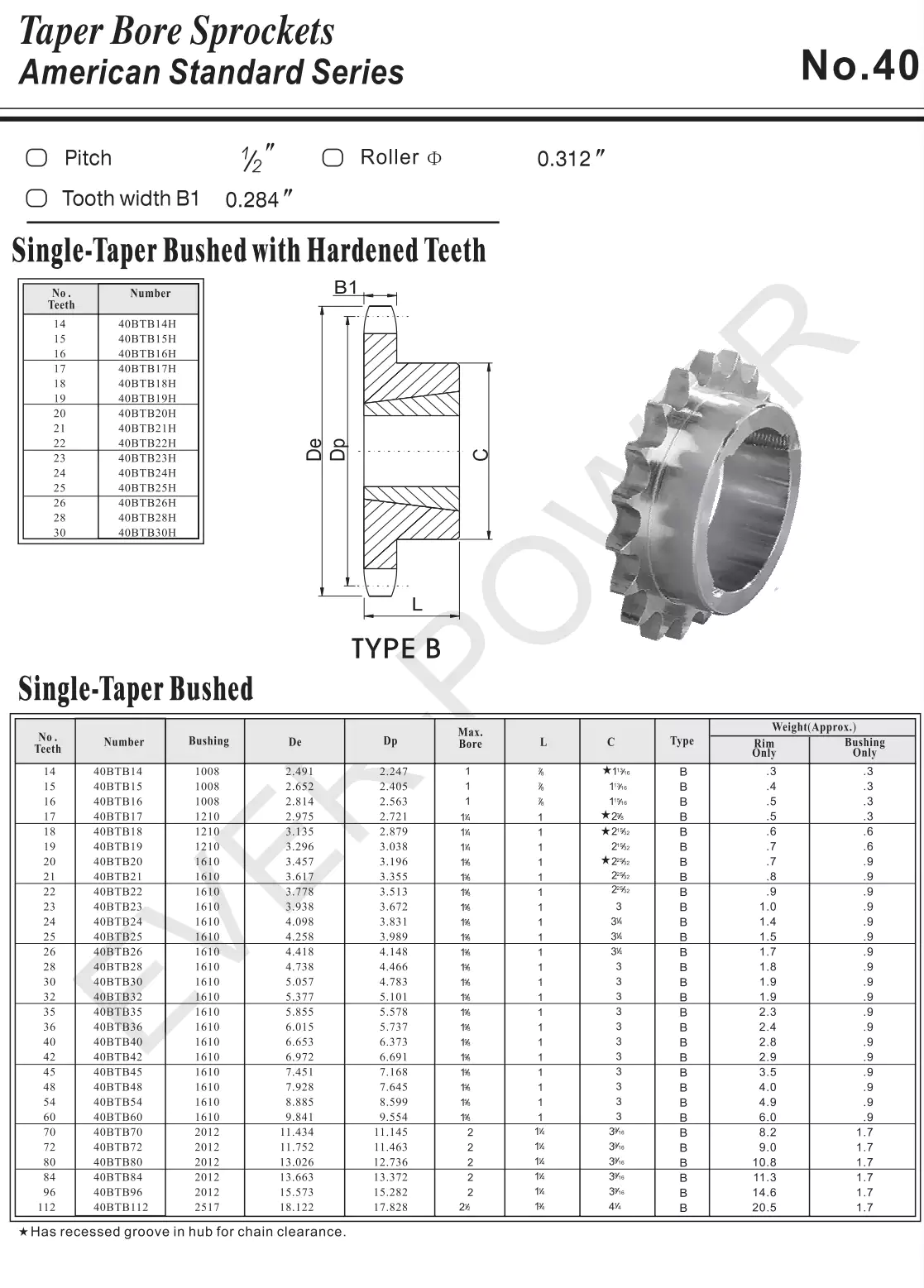

#40 1/2" Taper Lock Sprocket Specifications

#40 1/2" Taper Lock Sprocket is a specialized sprocket used in power transmission systems. Its design features a taper bore that allows it to be securely attached to a shaft via a taper lock bushing. This sprocket type is popular in various industrial settings due to its precision and dependability.

Definition and Basic Structure of Taper Lock Sprocket

A taper lock sprocket is characterized by its tapered bore, enabling attachment to a shaft through a taper lock bushing. The fundamental components of a taper lock sprocket include a hub, a toothed wheel, and the taper lock bushing.

Features and Functions of Taper Lock Sprocket

- Easy to Install: The installation and removal process for taper lock sprockets is straightforward, thanks to the taper lock bushing.

- High Precision Positioning: The taper lock bushing ensures accurate positioning of the sprocket on the shaft.

- Wide Applicability: These sprockets can serve multiple industrial applications.

- Reliability: Taper lock sprockets offer reliability, capable of handling heavy loads and challenging working conditions.

- Low Maintenance Cost: The straightforward design and ease of installation contribute to low maintenance costs.

The ease of installation and removal is particularly significant, as it conserves time and effort during maintenance and repairs. Taper lock sprockets are frequently utilized in conveyor systems, agricultural machinery, and various industrial equipment.

Installation and Removal Process of Taper Lock Sprocket

The installation and removal of a taper lock sprocket can be accomplished through the following steps:

- Prepare Tools and Materials: Gather the essential tools and materials, including a torque wrench, taper lock bushing, and sprocket.

- Clean Shaft and Sprocket Surface: Clean both the shaft and sprocket surfaces to eliminate dirt or debris.

- Place Taper Lock Bushing: Position the taper lock bushing onto the shaft and secure it with the set screws.

- Install Sprocket: Slide the sprocket onto the taper lock bushing and align it properly with the shaft.

- Tighten Locking Nut: Use a torque wrench to tighten the locking nut according to the manufacturer's torque specifications.

Adhering to the manufacturer's guidelines and torque specifications during the installation and removal process is crucial for ensuring the system's safety and reliability.

Features of Taper Lock Sprocket

The #40 1/2" Taper Lock Sprocket is widely recognized for its ease of use, precision, and broad applicability across industries. Its structure and function are designed to deliver dependable performance in demanding environments.

Sprockets Supplier in Australia

GBC is the official sales agent for Ever-power Group in Australia, offering a wide range of high-quality sprockets and related products. One of our key offerings is the #40 1/2" Taper Lock Sprocket, designed for durability and optimal performance in various industrial applications. Our sprockets are manufactured using premium materials to ensure longevity and reliability, making them ideal for heavy-duty use.

In addition to our standard sprocket line, we specialize in custom solutions tailored to meet the specific needs of our clients. We invite all customers to bring their designs and samples for non-standard customization. Our dedicated team is ready to assist you in creating the perfect sprocket to fit your unique requirements.

Additional information

| Edited by | Sylvia |

|---|