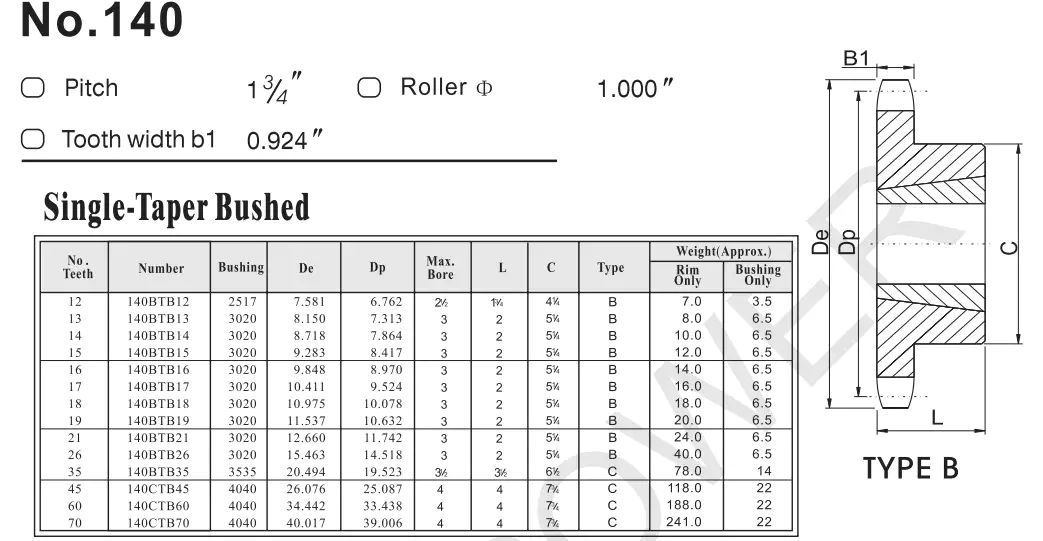

#140 1 3/4" Taper Lock Sprocket Specifications

#140 1 3/4" Taper Lock Sprocket is a type of sprocket commonly used in power transmission systems. It features a taper lock bushing to ensure a secure and reliable connection between the sprocket and the shaft. This taper lock system allows for easy installation and removal of the sprocket, making it a convenient choice for various industrial applications.

Definition and Basic Structure

A taper lock sprocket has a tapered bore designed to accommodate the taper lock bushing. The basic structure includes teeth that mesh with the chain, a hub that connects the sprocket to the shaft, and a taper lock bushing that ensures a secure connection.

Characteristics and Functions

Taper lock sprockets possess several key characteristics and functions:

- Easy Installation: The taper lock system enables quick and straightforward installation of the sprocket onto the shaft.

- High Precision Positioning: The taper lock bushing ensures accurate positioning of the sprocket on the shaft, reducing misalignment and wear.

- Wide Applicability: Taper lock sprockets are extensively used in various industries and applications due to their versatility.

- Reliability: The taper lock system offers a secure connection, minimizing the risk of slippage or disengagement.

- Low Maintenance Cost: Taper lock sprockets require minimal maintenance, which decreases downtime and overall maintenance expenses.

A notable advantage of taper lock sprockets is their ease of installation and removal. The taper lock bushing allows for effortless mounting and dismounting of the sprocket, saving time and effort during maintenance or replacement.

Installation and Removal Process

The installation and removal process of a taper lock sprocket involves the following steps:

- Prepare Tools and Materials: Gather the necessary tools and materials, including the taper lock bushing, key, and wrench.

- Clean Shaft and Sprocket Surface: Ensure that both the shaft and sprocket surfaces are clean and free from debris or contaminants.

- Place Taper Lock Bushing: Slide the taper lock bushing onto the shaft, making sure it is correctly positioned.

- Install Sprocket: Align the sprocket with the taper lock bushing and slide it onto the shaft until it is snugly fitted.

- Tighten Locking Nut: Use a wrench to tighten the locking nut, ensuring the sprocket is securely fastened to the taper lock bushing.

Manufacturing Process of Sprockets

The manufacturing process of sprockets typically includes the following steps:

- Prepare Raw Materials: Select high-quality materials suitable for sprocket production.

- Cutting: Cut the raw material into the desired shape and size.

- Forging or Casting: Form the sprocket through either forging or casting, based on the manufacturing technique used.

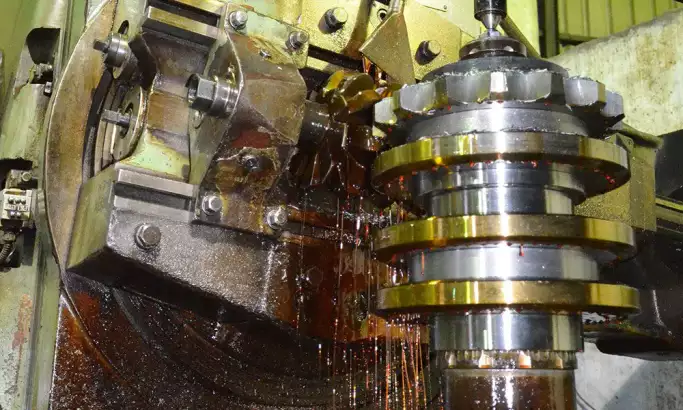

- Machining: Utilize various machining processes to refine the shape, dimensions, and teeth of the sprocket.

- Gear Cutting: Cut the teeth of the sprocket using specialized gear cutting tools.

- Heat Treatment: Apply heat treatment to enhance the hardness and durability of the sprocket.

- Surface Treatment: Apply surface treatments such as plating or coating to improve corrosion resistance.

- Quality Inspection: Conduct rigorous quality inspections to ensure the sprocket meets the required specifications and standards.

Sprockets Supplier in Australia

GBC is the sales agent for Ever-power Group in Australia, specializing in providing high-quality sprockets and related products. One of our key offerings is the #140 1 3/4" Taper Lock Sprocket, which is designed for reliable performance in various applications. Our sprockets are manufactured using durable materials, ensuring longevity and efficiency in operation. We pride ourselves on our exceptional customer service, guiding clients through their selection process to find the perfect components for their needs.

In addition to standard sprockets, we also offer customized solutions tailored to client specifications. Whether you have specific designs or need unique sizes, we welcome customers to provide drawings or samples for non-standard customizations. Your satisfaction is our priority.

Additional information

| Edited by | Sylvia |

|---|