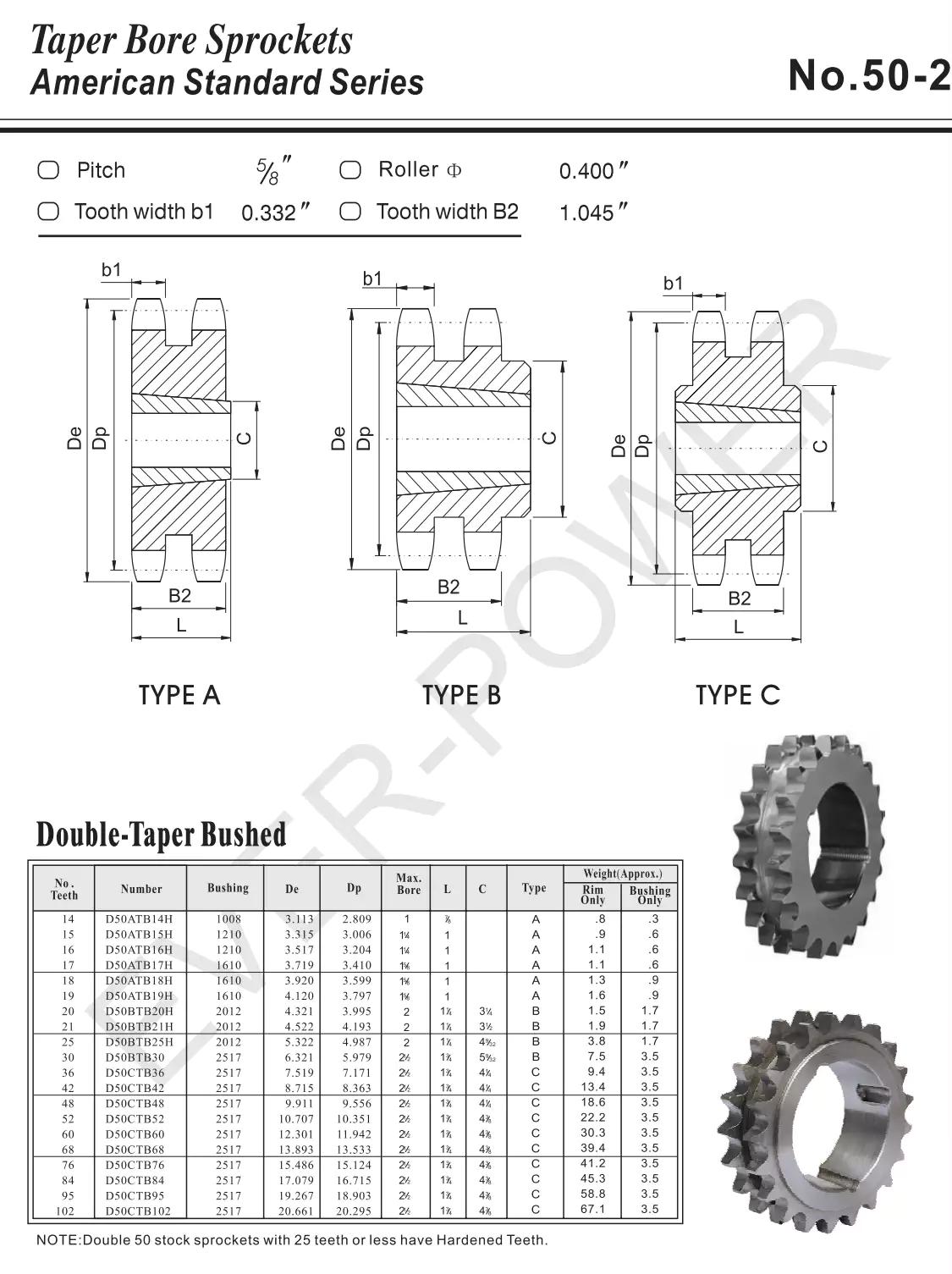

#50-2 5/8" Taper Lock Sprocket Specifications

The #50-2 5/8" Taper Lock Sprocket is a crucial component used in power transmission systems. Featuring a taper lock mechanism, it facilitates straightforward installation and removal. This sprocket efficiently transmits power between shafts, ensuring smooth operation.

Definition and Basic Structure

A taper lock sprocket, such as the #50-2 5/8", includes a tapered bore and is constructed from high-quality steel. It has teeth that interact with the drive chain, and the taper lock mechanism allows easy mounting and dismounting on the shaft, ensuring a secure connection.

Characteristics and Functions

- Easy Installation: The taper lock design streamlines the installation process, saving time and effort.

- High Precision Positioning: The mechanism guarantees precise alignment, reducing risks of misalignment.

- Wide Applicability: These sprockets are utilized across various industries, including manufacturing, agriculture, and mining.

- Reliability: The robust connection ensures dependable power transmission, even under heavy loads.

- Low Maintenance Cost: They require minimal upkeep, leading to cost savings for businesses.

One significant benefit of taper lock sprockets is the simplicity of their installation and removal. The taper lock system allows for quick and easy mounting and dismounting without needing complex tools, making maintenance and replacement tasks more efficient.

Installation and Removal Process

- Prepare Tools and Materials: Gather necessary tools such as a torque wrench, hex keys, and anti-seize compound.

- Clean Shaft and Sprocket Surface: Ensure both surfaces are clean and free from debris that could affect installation.

- Place Taper Lock Bushing: Insert the taper lock bushing into the sprocket bore, ensuring it aligns with the keyway on the shaft.

- Install Sprocket: Slide the sprocket onto the shaft, engaging the teeth with the drive chain, and align it properly with other components.

- Tighten Locking Nut: Use a torque wrench to tighten the locking nut, ensuring proper tension and secure attachment of the sprocket.

Manufacturing Process

- Prepare Raw Materials: Choose high-quality steel or suitable materials for manufacturing.

- Cutting: Shape the raw material to form the base of the sprocket.

- Forging or Casting: Utilize these techniques to create the sprocket, ensuring desired strength and durability.

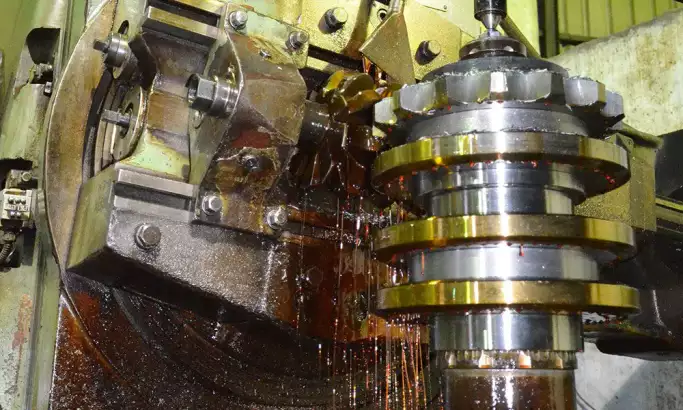

- Machining: Execute precise machining to create the teeth and other details.

- Gear Cutting: Use specialized tools to form the gear teeth for effective power transmission.

- Heat Treatment: Enhance hardness, strength, and wear resistance through heat treatment.

- Surface Treatment: Apply coatings or plating to protect against corrosion and improve aesthetics.

- Quality Inspection: Conduct thorough inspections to ensure compliance with standards.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, a leading manufacturer of industrial components. We specialize in providing high-quality taper bore sprockets, including the #50-2 5/8" Taper Lock Sprocket, which is designed for optimal performance and durability in various applications. Our product range ensures that we meet the diverse needs of our customers, whether for standard or specialized requirements.

In addition to our standard sprockets for sale, we offer non-standard customization services based on customer specifications. We invite all clients to send us their designs or samples for tailored solutions that perfectly fit their operational needs.