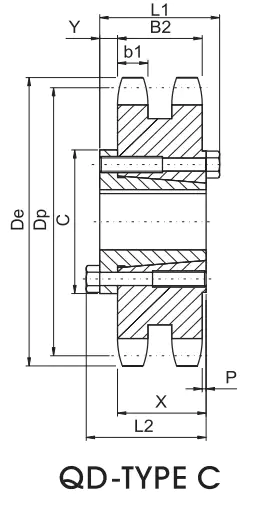

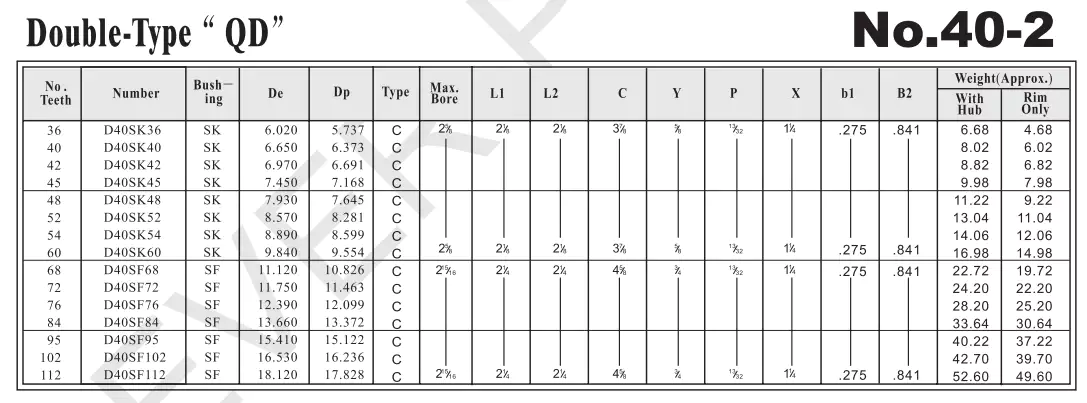

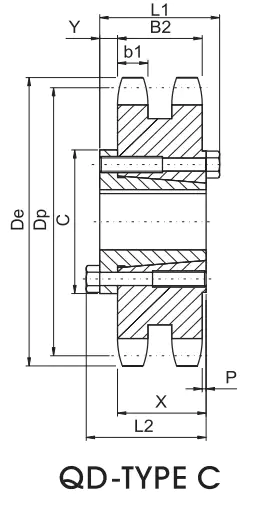

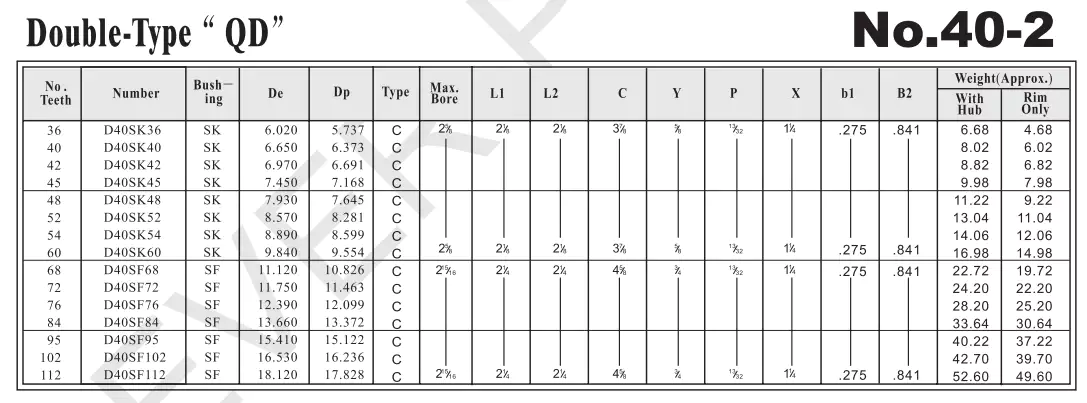

#40-2 1/2" Pitch QD Sprocket Specifications

QD Sprocket No.40-2 Double Type is a type of sprocket utilized in power transmission systems. It is crafted to offer a dependable and efficient method of transferring power between two rotating shafts.

Definition and Basic Structure of QD Sprocket

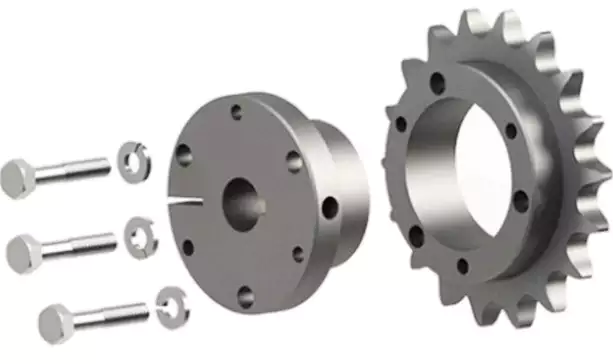

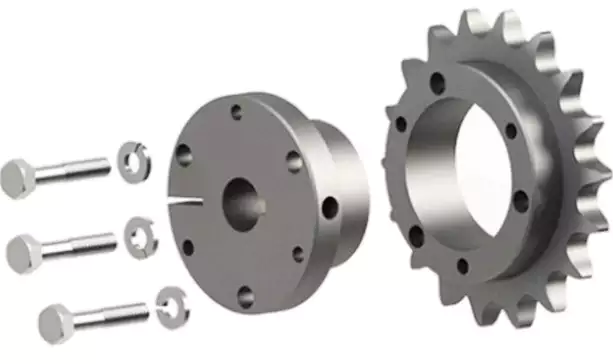

QD sprocket is a category of sprocket that employs a QD bushing for mounting onto a shaft. The QD bushing features a split taper design, comprising two halves that are fastened together. The sprocket itself has teeth on its outer edge, which engage with the chain to facilitate power transmission.

Features and Functions of QD Bushing

- Easy to install: QD bushings are designed for straightforward installation and removal, making them suitable for applications requiring regular maintenance.

- High load capacity: QD bushings are capable of supporting high loads, ideal for heavy-duty applications.

- Standardized design: QD bushings have a standardized design, ensuring interchangeability with other QD bushings of the same size.

- Compact design: The compact design of QD bushings makes them suitable for scenarios where space is restricted.

- Low maintenance cost: Minimal maintenance is required for QD bushings, contributing to reduced operational costs.

In summary, the QD bushing ensures a reliable mounting of the sprocket onto the shaft while offering substantial load capacity and maintenance ease.

Installation and Removal Process of QD Bushing

The following steps detail the process for installing and removing a QD bushing:

- Prepare tools and materials: Assemble all necessary tools and materials for the installation or removal.

- Clean shaft and sprocket surfaces: Clean the surfaces of the shaft and sprocket to ensure proper fitting and alignment.

- Position sprocket: Place the sprocket onto the shaft in the desired position.

- Install QD bushing: Fit the QD bushing onto the shaft, ensuring it aligns correctly with the sprocket.

- Secure sprocket: Bolt the two halves of the QD bushing together to secure the sprocket onto the shaft.

- Check: Verify the alignment and tightness of both the sprocket and QD bushing to ensure proper functionality.

Manufacturing Process of QD Sprocket

The manufacturing steps for QD sprockets generally include the following:

- Prepare raw materials: Acquire raw materials, typically made from high-quality steel.

- Cut or forge: Cut or forge the raw materials into the required shape and dimensions for the sprocket.

- Machining: Employ a CNC machine to perform machining operations on the sprocket, including drilling, milling, and turning.

- Rolling the teeth: Utilize a specialized machine to roll the teeth onto the sprocket.

- Heat treatment: Heat treat the sprocket to enhance its strength and durability.

- Surface treatment: Apply a protective surface treatment, such as plating or painting, to safeguard the sprocket against corrosion and wear.

- Quality inspection: Conduct quality inspections to ensure the sprocket meets all relevant industry standards.

Sprockets Supplier in Australia

GBC is the sales agent for Ever-power Group in Australia, providing high-quality power transmission solutions to meet various industrial needs.

Introduction to QD Sprocket No.40-2 Double Type

QD Sprocket No.40-2 Double Type is a type of sprocket that is used in power transmission systems. It is designed to provide a reliable and efficient means of transmitting power between two rotating shafts.

Definition and Basic Structure of QD Sprocket

QD sprocket is a type of sprocket that uses a QD bushing to mount onto a shaft. The QD bushing is a split taper bushing that consists of two halves that are bolted together. The sprocket itself has teeth on its outer circumference, which engage with the chain to transmit power.

Features and Functions of QD Bushing

- Easy to install: QD bushings are designed for easy installation and removal, which makes them ideal for applications where frequent maintenance is required.

- High load capacity: QD bushings can handle high loads, which makes them ideal for heavy-duty applications.

- Standardized design: QD bushings have a standardized design, which makes them interchangeable with other QD bushings of the same size.

- Compact design: QD bushings have a compact design, which makes them ideal for applications where space is limited.

- Low maintenance cost: QD bushings require minimal maintenance, which helps to reduce operating costs.

Overall, the QD bushing provides a reliable means of mounting the sprocket onto the shaft, while also providing a high level of load capacity and ease of maintenance.

Installation and Removal Process of QD Bushing

The following steps outline the process for installing and removing a QD bushing:

- Prepare tools and materials: Gather all the necessary tools and materials for the installation or removal process.

- Clean shaft and sprocket surfaces: Clean the shaft and sprocket surfaces to ensure a proper fit and alignment.

- Position sprocket: Position the sprocket onto the shaft in the desired location.

- Install QD bushing: Install the QD bushing onto the shaft, making sure that it is properly aligned with the sprocket.

- Secure sprocket: Bolt the two halves of the QD bushing together to secure the sprocket onto the shaft.

- Check: Check the alignment and tightness of the sprocket and QD bushing to ensure proper operation.

Manufacturing Process of QD Sprocket

The manufacturing process of QD sprockets typically involves the following steps:

- Prepare raw materials: Prepare the raw materials, which are typically made of high-quality steel.

- Cut or forge: Cut or forge the raw materials into the desired shape and size for the sprocket.

- Machining: Use a CNC machine to perform machining operations on the sprocket, such as drilling, milling, and turning.

- Rolling the teeth: Roll the teeth onto the sprocket using a specialized machine.

- Heat treatment: Heat treat the sprocket to improve its strength and durability.

- Surface treatment: Apply a surface treatment, such as plating or painting, to protect the sprocket from corrosion and wear.

- Quality inspection: Inspect the sprocket for quality and ensure that it meets all relevant industry standards.

FAQ

- Q: What is the maximum load capacity of a QD sprocket?

A: The maximum load capacity of a QD sprocket depends on its size and the specific application in which it is being used. - Q: How do I know which size QD bushing to use for my sprocket?

A: The size of the QD bushing needed depends on the bore diameter of the sprocket and the size of the shaft it will be mounted on. Consult the manufacturer's specifications for the correct size. - Q: What is the advantage of using a QD bushing instead of a set screw?

A: QD bushings provide a more secure and reliable means of mounting the sprocket onto the shaft than set screws, which can loosen over time and cause the sprocket to slip or become misaligned. - Q: What maintenance is required for a QD bushing?

A: QD bushings require minimal maintenance. Periodic inspection and cleaning is recommended to ensure proper operation. - Q: Can QD bushings be reused?

A: Yes, QD bushings can be reused as long as they are not damaged or worn.

At GBC, we offer a wide range of products and services, including the #40-2 1/2" Pitch QD Sprocket. Our solutions are tailored to meet the specific needs of our clients, ensuring optimal performance and reliability. In addition to standard sprockets, we also provide custom solutions based on customer requirements. We invite all customers to reach out with their designs or samples for non-standard customization.

Additional information

| Edited by | Sylvia |

|---|