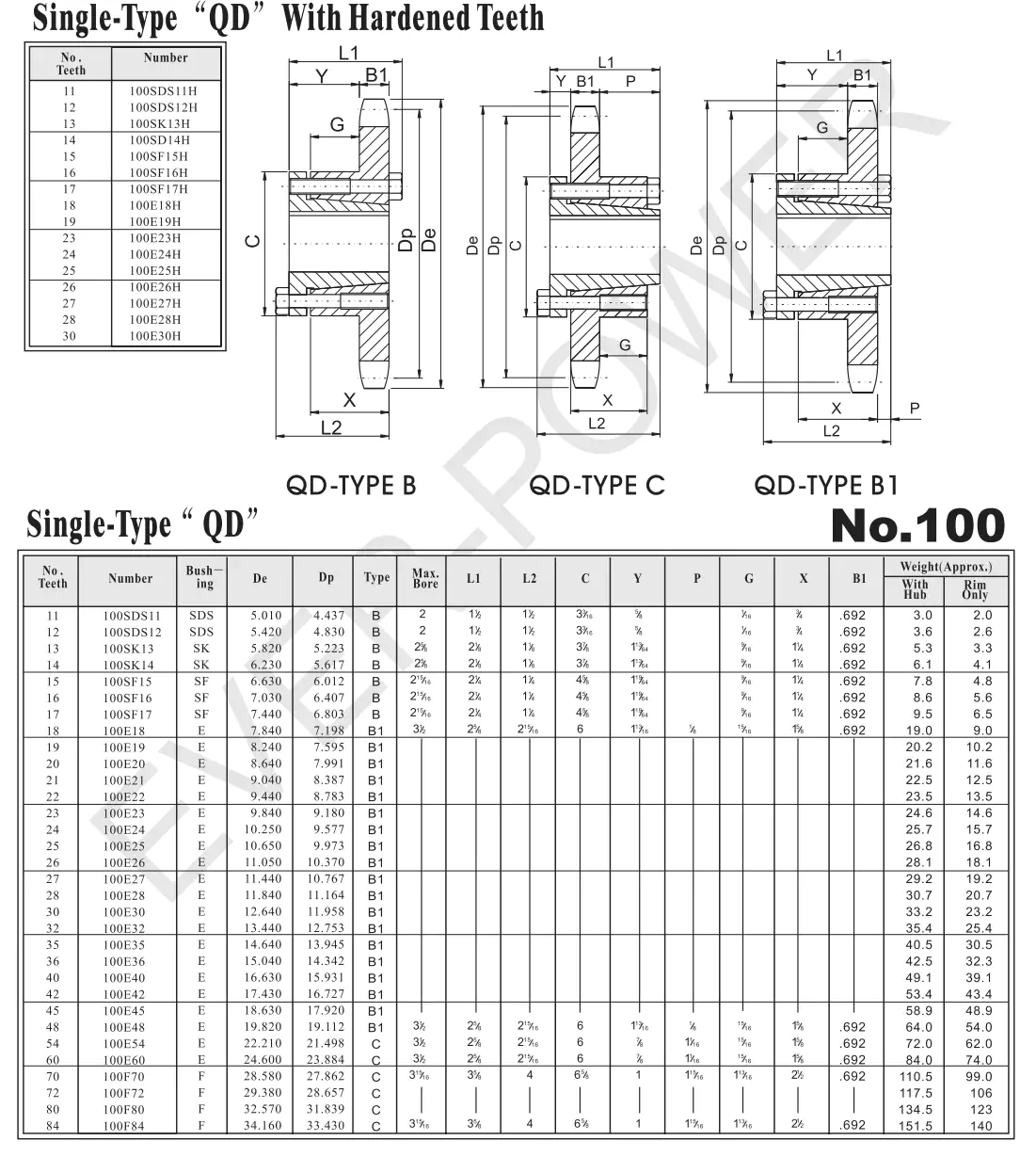

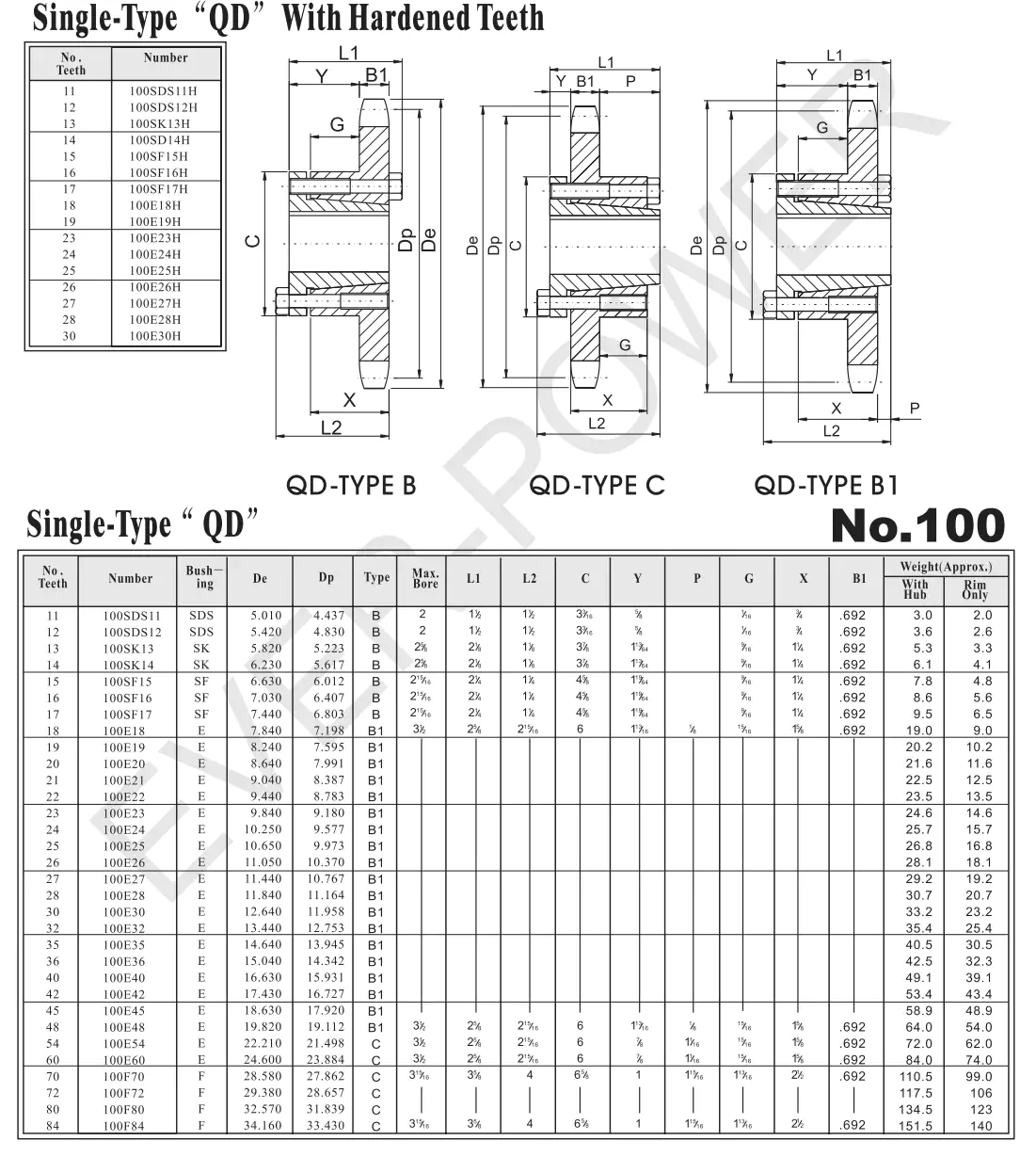

#100 1-1/4" Pitch QD Sprocket Specifications

QD Sprocket No.100 Single Type is a type of sprocket that is commonly used in power transmission systems. QD sprockets are designed to fit a particular size of bushing that can be easily mounted and dismounted from the sprocket bore. They are commonly employed in applications where frequent sprocket changes are required.

Definition and Basic Structure of QD Sprocket

QD sprocket consists of a sprocket with a specific pitch diameter and a QD bushing that is mounted in the bore of the sprocket. The QD bushing is designed to fit a specific shaft diameter and can be easily mounted and dismounted from the sprocket bore.

Features and Functions of QD Bushing

QD bushing has the following features and functions:

- Easy to install

- High load carrying capacity

- Standardized design

- Compact design

- Low maintenance cost

QD bushing is easy to install and disassemble, which saves time and effort during installation and maintenance. Its standardized and compact design allows for easy replacement and interchangeability of components.

Easy to Install

QD bushing is designed to be easily mounted and dismounted from the sprocket bore with the use of a hex key. This allows for quick and easy installation and replacement of sprockets.

High Load Carrying Capacity

QD bushing has a high load carrying capacity due to its design and material composition. It is able to handle heavy loads and provide reliable performance in power transmission systems.

Standardized Design

QD bushing has a standardized design that allows for easy replacement and interchangeability of components. This reduces downtime and maintenance costs for power transmission systems.

Compact Design

QD bushing has a compact design that allows for a smaller overall sprocket diameter. This makes it suitable for use in tight spaces and applications where space is limited.

Low Maintenance Cost

QD bushing has a low maintenance cost due to its easy installation and standardized design. It requires minimal maintenance and can be easily replaced when necessary.

Installation and Disassembly Process of QD Bushing

The installation and disassembly process of QD bushing involves the following steps:

- Prepare tools and materials

- Clean the shaft and sprocket surface

- Position the sprocket

- Install QD bushing

- Secure the sprocket

- Check for proper installation

Each step should be performed carefully to ensure proper installation and alignment of the sprocket.

Manufacturing Process of QD Sprocket

The manufacturing process of QD sprocket involves the following steps:

- Prepare raw materials

- Cut and shape raw materials

- Forge or cast sprocket

- Machine sprocket to final dimensions

- Roll teeth onto sprocket

- Heat treat sprocket for hardness and durability

- Apply surface treatment

- Perform quality inspection

Each step is critical to the production of a high quality QD sprocket that meets industry standards.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, providing high-quality sprockets and related products to meet various industrial needs.

Introduction to QD Sprocket No.100 Single Type

QD Sprocket No.100 Single Type is a type of sprocket that is commonly used in power transmission systems. QD sprockets are designed to fit a particular size of bushing that can be easily mounted and dismounted from the sprocket bore. They are commonly used in applications where frequent sprocket changes are required.

Definition and Basic Structure of QD Sprocket

QD sprocket consists of a sprocket with a specific pitch diameter and a QD bushing that is mounted in the bore of the sprocket. The QD bushing is designed to fit a specific shaft diameter and can be easily mounted and dismounted from the sprocket bore.

Features and Functions of QD Bushing

- Easy to install

- High load carrying capacity

- Standardized design

- Compact design

- Low maintenance cost

QD bushing is easy to install and disassemble, which saves time and effort during installation and maintenance. Its standardized and compact design allows for easy replacement and interchangeability of components.

Easy to Install

QD bushing is designed to be easily mounted and dismounted from the sprocket bore with the use of a hex key. This allows for quick and easy installation and replacement of sprockets.

High Load Carrying Capacity

QD bushing has a high load carrying capacity due to its design and material composition. It is able to handle heavy loads and provide reliable performance in power transmission systems.

Standardized Design

QD bushing has a standardized design that allows for easy replacement and interchangeability of components. This reduces downtime and maintenance costs for power transmission systems.

Compact Design

QD bushing has a compact design that allows for a smaller overall sprocket diameter. This makes it suitable for use in tight spaces and applications where space is limited.

Low Maintenance Cost

QD bushing has a low maintenance cost due to its easy installation and standardized design. It requires minimal maintenance and can be easily replaced when necessary.

Installation and Disassembly Process of QD Bushing

The installation and disassembly process of QD bushing involves the following steps:

- Prepare tools and materials

- Clean the shaft and sprocket surface

- Position the sprocket

- Install QD bushing

- Secure the sprocket

- Check for proper installation

Each step should be performed carefully to ensure proper installation and alignment of the sprocket.

Manufacturing Process of QD Sprocket

The manufacturing process of QD sprocket involves the following steps:

- Prepare raw materials

- Cut and shape raw materials

- Forge or cast sprocket

- Machine sprocket to final dimensions

- Roll teeth onto sprocket

- Heat treat sprocket for hardness and durability

- Apply surface treatment

- Perform quality inspection

Each step is critical to the production of a high quality QD sprocket that meets industry standards.

FAQ (Frequently Asked Questions)

Q: What is QD Sprocket No.100 Single Type used for?

A: QD Sprocket No.100 Single Type is commonly used in power transmission systems where frequent sprocket changes are required.

Q: What is QD bushing and how does it work?

A: QD bushing is a component that is mounted in the bore of a sprocket to fit a specific shaft diameter. It allows for easy installation and disassembly of the sprocket.

Q: What are the advantages of QD bushing?

A: QD bushing is easy to install and disassemble, has a high load carrying capacity, standardized design, compact design, and low maintenance cost.

Q: How do I install QD bushing?

A: To install QD bushing, prepare tools and materials, clean the shaft and sprocket surface, position the sprocket, install QD bushing, secure the sprocket, and check for proper installation.

Q: What is the manufacturing process for QD sprocket?

A: The manufacturing process for QD sprocket involves preparing raw materials, cutting and shaping raw materials, forging or casting the sprocket, machining the sprocket to final dimensions, rolling teeth onto the sprocket, heat treating the sprocket, applying surface treatment, and performing quality inspection.

Author: Miya

We offer a range of products and services, including the #100 1-1/4" Pitch QD Sprocket, designed to meet the diverse needs of our clients. In addition to standard sprockets, we provide non-standard customization according to customer requirements. We welcome all clients to submit their drawings or samples for custom solutions.

Additional information

| Edited by | Sylvia |

|---|