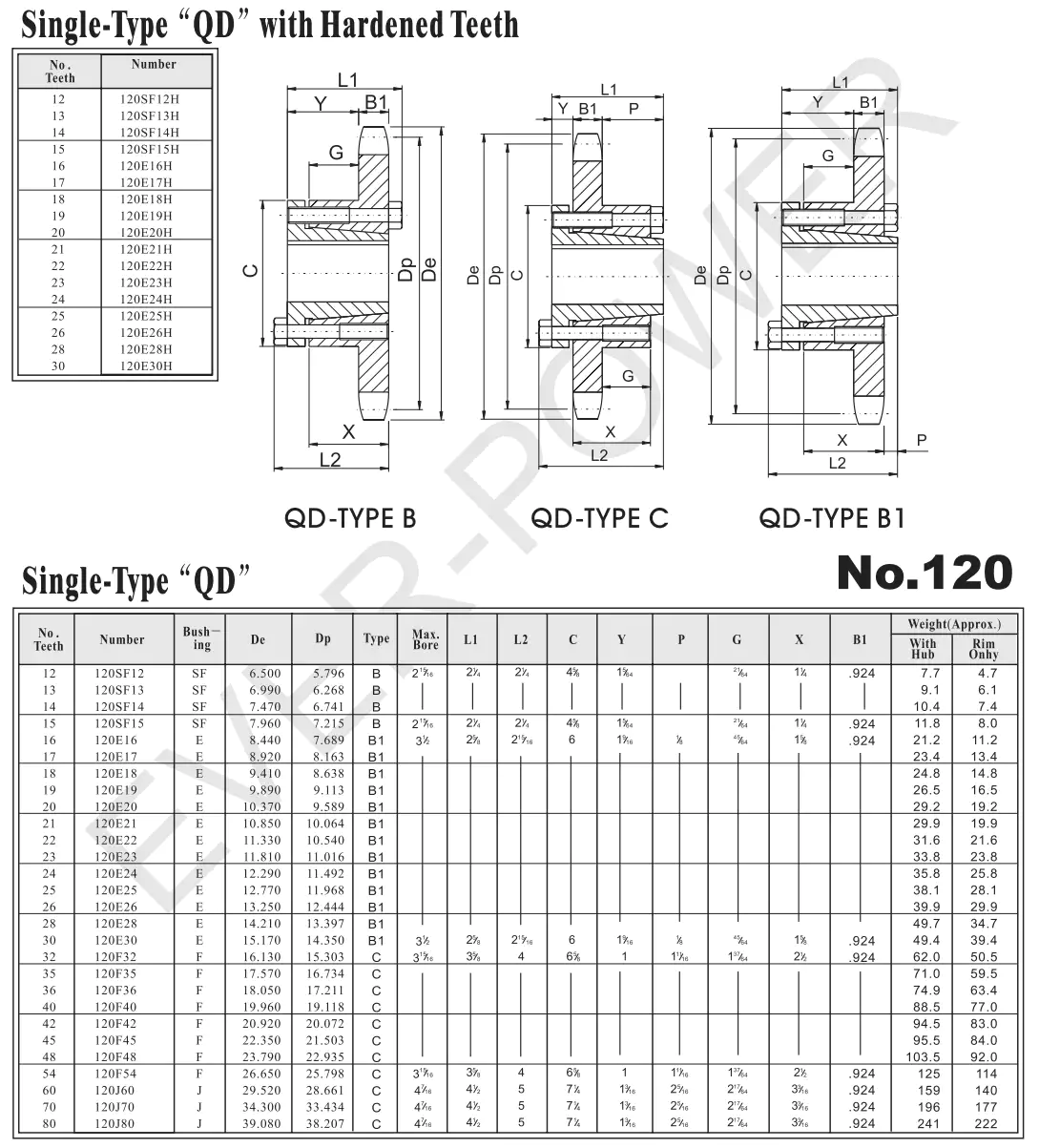

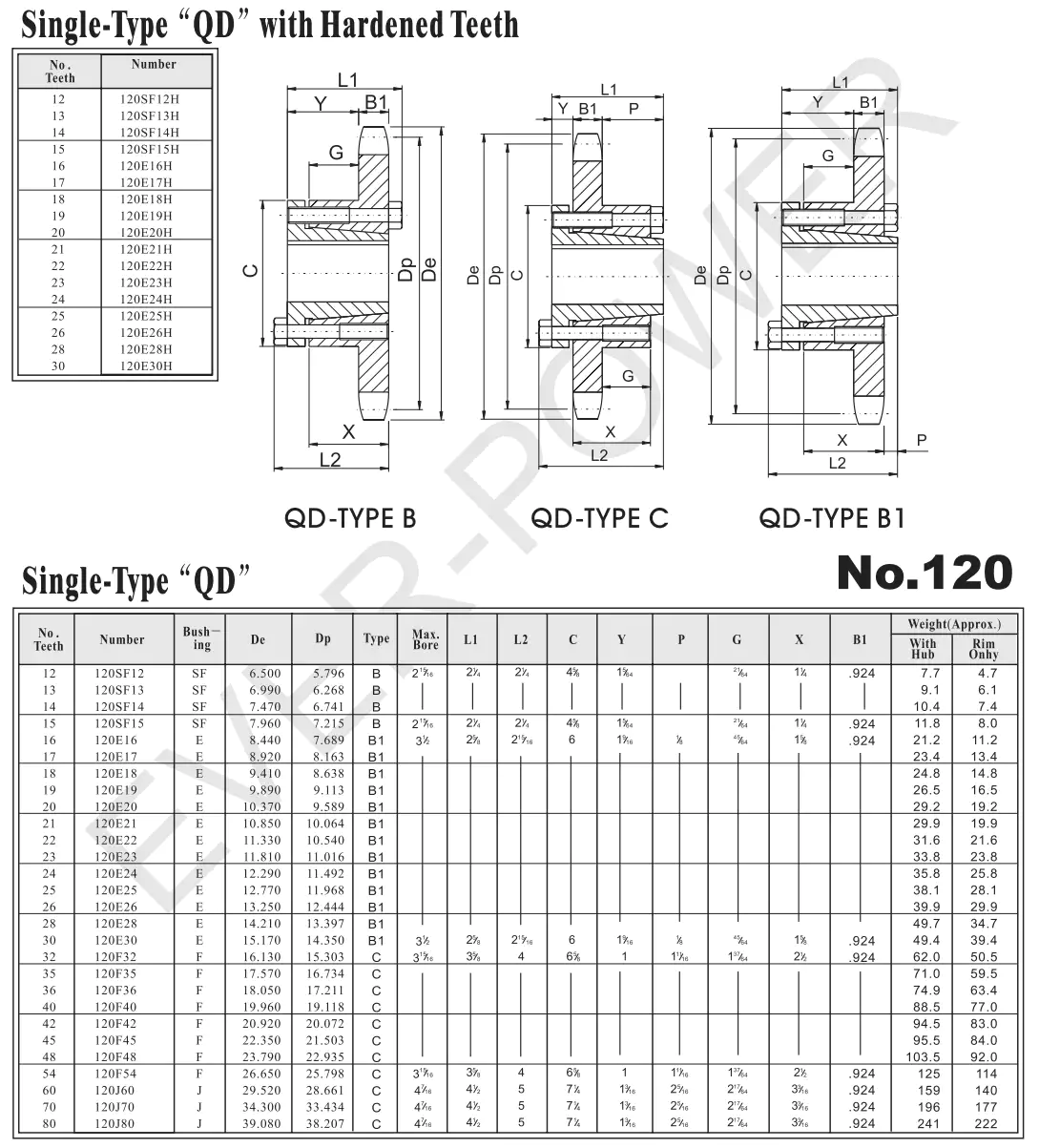

#120 1-1/2" Pitch QD Sprocket Specifications

QD Sprocket No.120 Single Type is a type of sprocket that is widely used in power transmission systems. It is designed to transmit torque and power from one rotating shaft to another. QD sprockets are an essential component of many machines, including conveyor systems, pumps, and industrial machinery.

Definition and Basic Structure of QD Sprocket

A QD sprocket consists of two main parts: the sprocket itself and the QD bushing. The sprocket is a toothed wheel that meshes with a chain to transmit power. The QD bushing is a component that is mounted on the sprocket hub and provides a secure and reliable connection to the shaft.

Features and Functions of QD Bushing

- Easy to Install: QD bushings can be easily installed and removed using basic tools, which minimizes downtime and maintenance costs.

- High Load Capacity: QD bushings can handle high loads and torque, which makes them suitable for heavy-duty applications.

- Standardized Design: QD bushings are designed to comply with industry standards, which ensures compatibility with other components and simplifies the selection process.

- Compact Design: QD bushings have a compact design that minimizes the space required for installation, which is beneficial in tight spaces.

- Low Maintenance Cost: QD bushings require minimal maintenance and are designed to last for a long time, which reduces overall maintenance costs.

QD bushings are an essential component of QD sprockets, and their features and functions make them a popular choice for power transmission systems.

Installation and Removal Process of QD Bushing

- Prepare Tools and Materials: Before installing or removing a QD bushing, make sure you have all the necessary tools and materials, including a torque wrench, a hammer, and a clean rag.

- Clean Shaft and Sprocket Surface: Use a clean rag to wipe the shaft and sprocket surface to remove any dirt or debris.

- Position the Sprocket: Slide the sprocket onto the shaft and position it in the desired location.

- Install QD Bushing: Slide the QD bushing onto the shaft and align it with the sprocket hub. Use a hammer to tap the bushing into place until it is snug against the sprocket hub.

- Secure Sprocket: Tighten the set screws on the QD bushing using a torque wrench to secure the sprocket in place.

- Check: Check the alignment of the sprocket and QD bushing to ensure they are properly installed and aligned.

The installation and removal process of QD bushings is relatively simple and can be completed with basic tools and materials.

Manufacturing Process of QD Sprocket

The manufacturing process of QD sprockets involves several steps, including:

- Raw Material Preparation: The raw materials, such as steel or cast iron, are prepared according to the required specifications.

- Cutting: The raw materials are cut into the desired shape and size using cutting tools.

- Forging or Casting: The sprocket or hub is either forged or cast to provide the required strength and durability.

- Machining: The sprocket teeth and hub are machined to the required dimensions and tolerances.

- Tooth Cutting: The teeth of the sprocket are cut using a specialized machine to ensure accurate and precise tooth profiles.

- Heat Treatment: The sprocket is heat-treated to provide the required hardness and toughness.

- Surface Treatment: The sprocket is finished with a protective coating or plating to prevent corrosion and wear.

- Quality Inspection: The finished sprocket undergoes a series of quality inspections to ensure it meets the required specifications.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, offering a wide range of high-quality sprockets to meet various industrial needs. Our flagship product, the QD Sprocket No.120 Single Type, is engineered for efficiency in power transmission systems, providing reliable torque transfer essential for machinery including conveyor systems and pumps.

In addition to our standard chain wheels, our company specializes in customized non-standard sprockets tailored to specific customer requirements. We encourage our clients to provide drawings or samples for bespoke solutions, ensuring each product meets their unique operational demands.

Additional information

| Edited by | Sylvia |

|---|