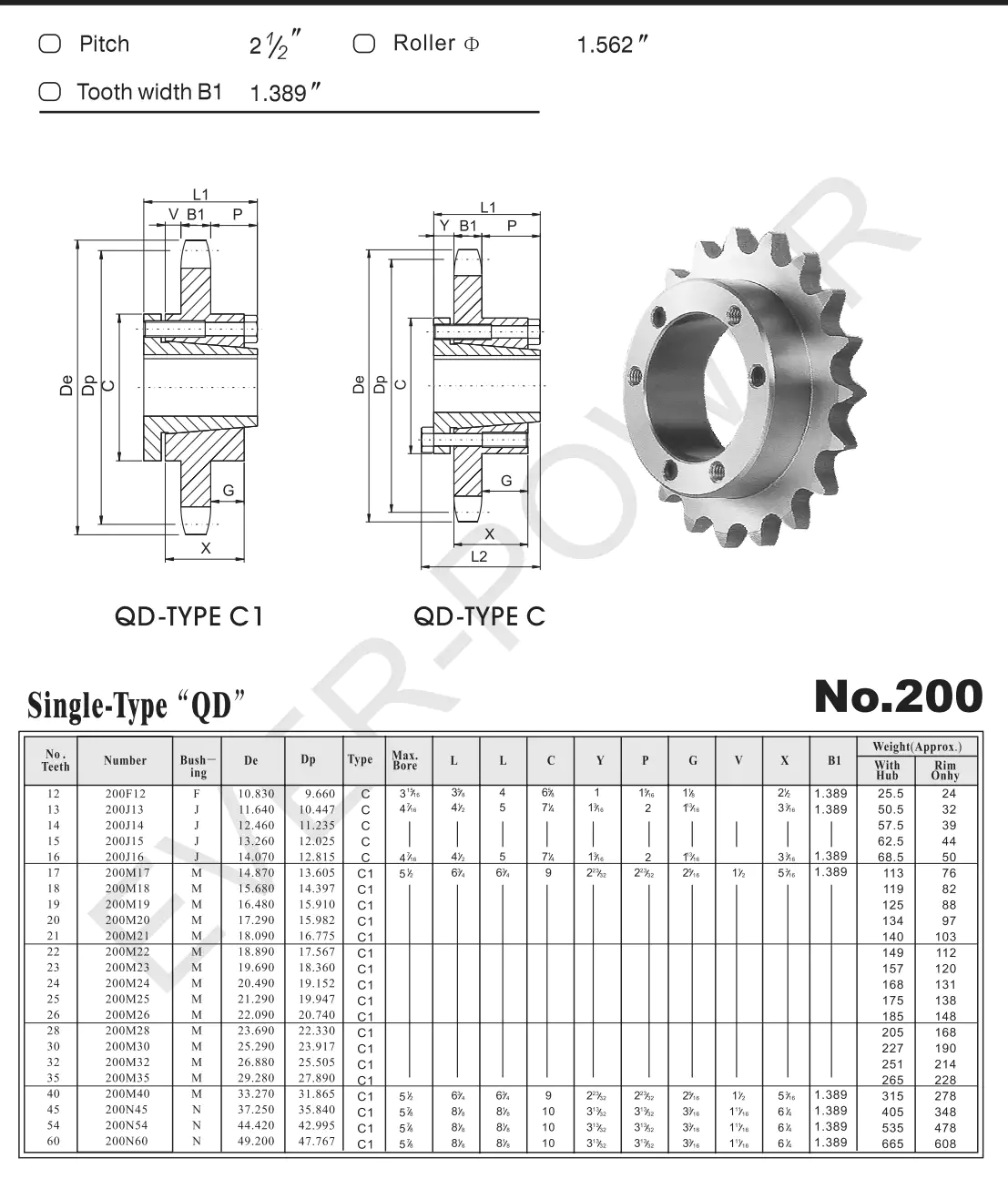

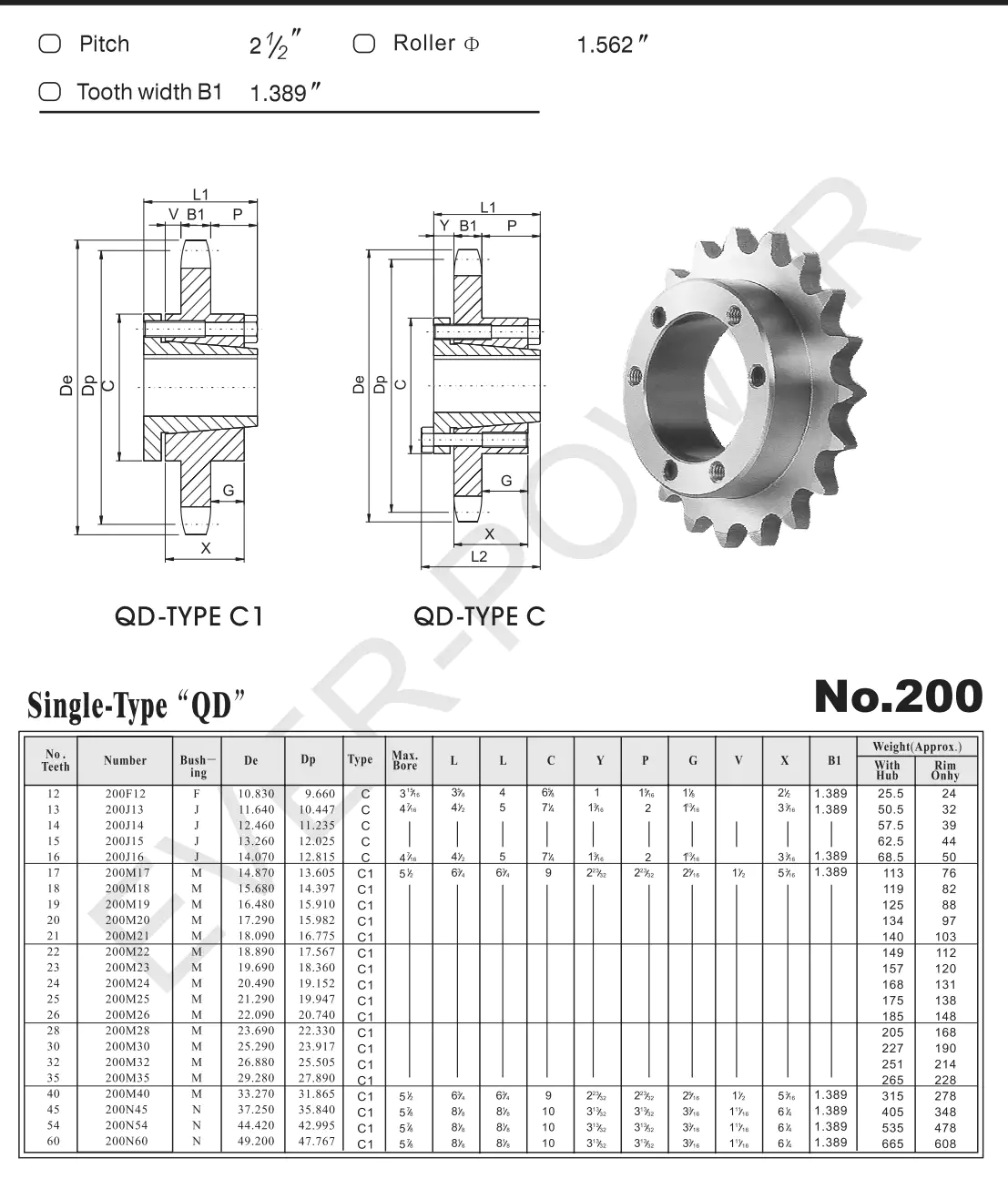

#200 2-1/2" Pitch QD Sprocket Specifications

QD Sprocket No.200 Single Type is a widely utilized chain sprocket in power transmission systems. It operates on the principle of transmitting power from one shaft to another through a chain. The sprocket features teeth that align with the chain's pitch, enabling it to rotate and transfer power effectively to the driven shaft.

Definition and Basic Structure of QD Sprocket

A QD sprocket is a chain sprocket characterized by a tapered bushing, which includes an internal keyway, allowing for quick and simple mounting or dismounting from the shaft without additional tools. The fundamental components of a QD sprocket include the sprocket wheel, hub, and bushing. The sprocket wheel features teeth that align with the chain's pitch, while the hub secures the sprocket, and the bushing connects the sprocket to the shaft.

Features and Functions of QD Bushing

QD bushing provides several benefits that contribute to its popularity in power transmission applications:

- Easy to install: The bushing can be quickly mounted or dismounted from the shaft without the need for additional tools.

- High load capacity: It can accommodate high torque and radial loads.

- Standardized design: The bushing adheres to industry standards, facilitating easy replacement and interchangeability.

- Compact design: Its small and lightweight nature makes it suitable for confined spaces.

- Low maintenance cost: It requires minimal maintenance, reducing overall costs.

Installation and Removal Process of QD Bushing

To install and remove a QD bushing, follow these steps:

- Prepare tools and materials: You will need a hammer, a torque wrench, a puller, and the appropriate bushing and sprocket.

- Clean shaft and sprocket surface: Remove any dirt or debris from both surfaces.

- Position sprocket: Slide the sprocket onto the shaft and place it in the desired position.

- Install QD bushing: Slide the QD bushing onto the shaft, ensuring the internal keyway engages with the shaft key.

- Secure sprocket: Tighten the set screws on the sprocket hub to secure it to the bushing.

- Check: Ensure that the sprocket is correctly aligned and the bushing is firmly mounted.

Manufacturing Process of QD Sprocket

The process of manufacturing a QD sprocket typically includes the following steps:

- Raw material preparation: Steel is selected and prepared for processing.

- Cutting: The material is cut into the desired dimensions using cutting equipment.

- Forging or casting: The material is heated and shaped using a forging press or casting mold.

- Machining: The sprocket is machined to specified dimensions and tooth profiles.

- Tooth rolling: The tooth profile is created using specialized rollers.

- Heat treatment: The sprocket undergoes heat treatment to enhance strength and durability.

- Surface treatment: A coating or plating is applied to improve corrosion resistance.

- Quality inspection: The sprocket is thoroughly inspected for defects and dimensional accuracy.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, providing high-quality industrial products and solutions across the region.

Introduction to QD Sprocket No.200 Single Type

QD Sprocket No.200 Single Type is a type of chain sprocket that is widely used in power transmission systems. The basic concept of a QD sprocket is to transmit power from one shaft to another using a chain. The sprocket has teeth that match the pitch of the chain, allowing it to rotate and transfer power to the driven shaft.

Definition and Basic Structure of QD Sprocket

QD sprocket is a type of chain sprocket that has a tapered bushing with an internal keyway that can be quickly and easily mounted or dismounted from the shaft without the need for additional tools. The basic structure of a QD sprocket consists of a sprocket wheel, a hub, and a bushing. The sprocket wheel has teeth that match the pitch of the chain, while the hub holds the sprocket in place and the bushing connects the sprocket to the shaft.

Features and Functions of QD Bushing

QD bushing has several advantages that make it a popular choice in power transmission systems:

- Easy to install: The bushing can be quickly mounted or dismounted from the shaft without the need for additional tools.

- High load capacity: The bushing can handle high torque and radial loads.

- Standardized design: The bushing conforms to industry standards, making it easy to replace and interchange.

- Compact design: The bushing is small and lightweight, making it suitable for use in tight spaces.

- Low maintenance cost: The bushing requires minimal maintenance, reducing overall maintenance costs.

Installation and Removal Process of QD Bushing

To install and remove a QD bushing, follow these steps:

- Prepare tools and materials: You will need a hammer, a torque wrench, a puller, and the appropriate bushing and sprocket.

- Clean shaft and sprocket surface: Remove any dirt or debris from the shaft and sprocket surface.

- Position sprocket: Slide the sprocket onto the shaft and position it in the desired location.

- Install QD bushing: Slide the QD bushing onto the shaft and engage the internal keyway with the shaft key.

- Secure sprocket: Tighten the set screws on the sprocket hub to secure it to the bushing.

- Check: Verify that the sprocket is properly aligned and the bushing is securely mounted.

Manufacturing Process of QD Sprocket

The manufacturing process of QD sprocket typically involves the following steps:

- Raw material preparation: The raw material, usually steel, is selected and prepared for processing.

- Cutting: The material is cut into the desired shape and size using a saw or other cutting equipment.

- Forging or casting: The material is heated and shaped using a forging press or casting mold.

- Machining: The sprocket is machined to the required dimensions and tooth profile.

- Tooth rolling: The tooth profile is created using a specialized tooth roller.

- Heat treatment: The sprocket is heat-treated to increase its strength and durability.

- Surface treatment: The sprocket is finished with a coating or plating to improve its corrosion resistance.

- Quality inspection: The sprocket is inspected for defects and dimensional accuracy.

FAQ

Q: What type of chain is compatible with QD Sprocket No.200 Single Type?

A: QD Sprocket No.200 Single Type is compatible with ANSI standard roller chains.

Q: What is the maximum torque that QD Sprocket No.200 Single Type can handle?

A: The maximum torque capacity depends on the specific QD bushing and sprocket size. Please refer to the manufacturer's specifications.

Q: Can QD bushings be reused?

A: QD bushings can be reused if they are not damaged or worn out. However, it is important to ensure that the new sprocket and bushing are properly matched before reusing the bushing.

Q: How do I remove a QD bushing from a shaft?

A: A QD bushing can be removed from a shaft using a puller or by tapping it gently with a hammer while applying pressure to the opposite end of the shaft.

Q: How do I select the right QD bushing and sprocket for my application?

A: The selection of QD bushing and sprocket depends on several factors, including shaft diameter, torque requirements, and operating conditions. It is recommended to consult with a qualified engineer or the manufacturer for assistance with selection.

Author: Miya

我们公司致力于提供高质量的链轮和相关产品,确保能满足客户的各种需求。除了标准链轮外,我们还可以根据客户的具体要求进行非标定制,欢迎广大客户来图来样定制。我们的产品广泛应用于机械、自动化及其他工业领域,旨在提供可靠的动力传输解决方案。

Additional information

| Edited by | Sylvia |

|---|