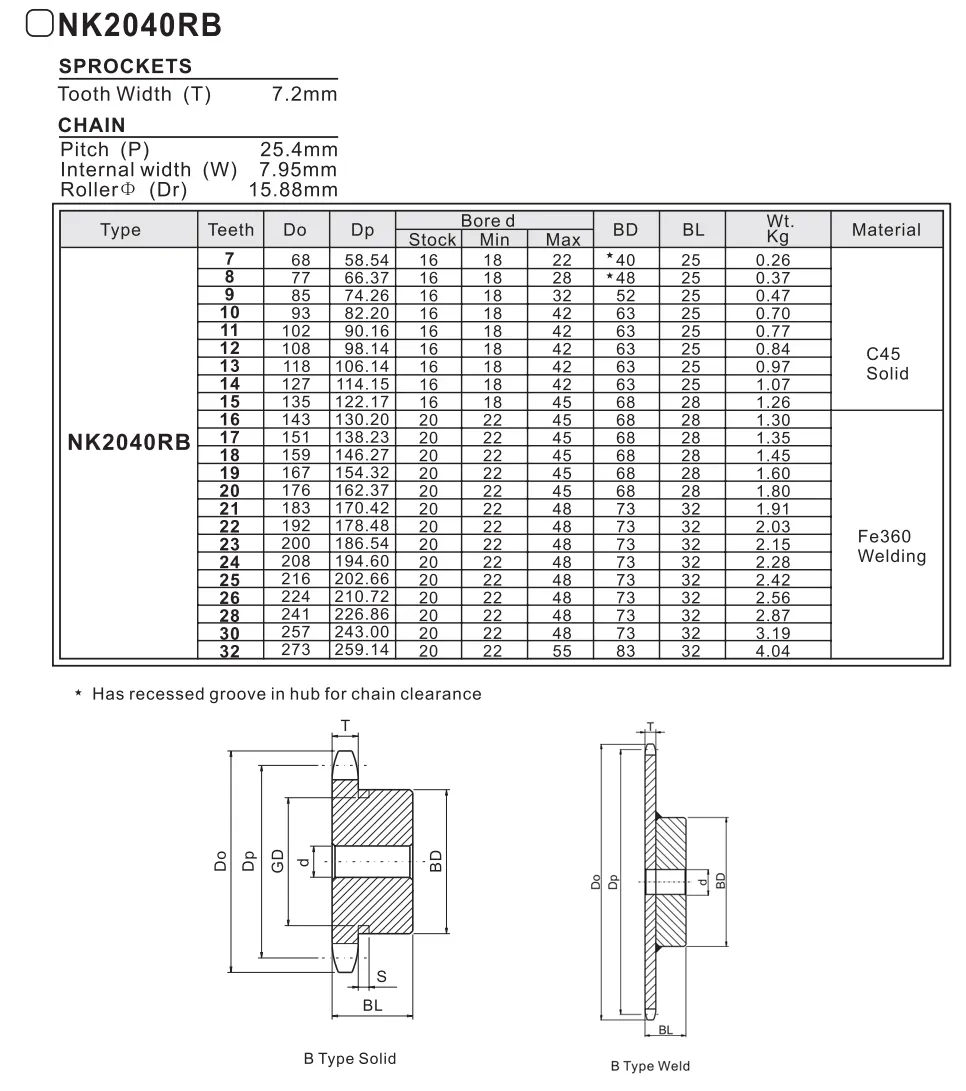

Specifications of NK2040RB Double Pitch Sprocket

The NK2040RB Double Pitch Sprocket is a vital element in transmission systems, widely utilized across various industries due to its distinctive design and functionality.

Definition and Basic Structure

The Double Pitch Sprocket is characterized by a larger pitch diameter and features longer distances between its teeth compared to standard sprockets. This unique design facilitates smoother and more efficient power transmission.

Main Features

- Larger tooth spacing: The Double Pitch Sprocket offers a wider gap between teeth, minimizing the chances of chain jamming and enhancing overall performance.

- Higher load capacity: Its robust construction allows the Double Pitch Sprocket to endure heavier loads without compromising functionality.

- Smooth operation: The design ensures smoother rotation, which leads to reduced noise and vibration.

Material Selection

Double Pitch Sprockets are typically crafted from three primary materials:

- Carbon steel: Renowned for its strength and durability, carbon steel sprockets are ideal for applications with moderate loads.

- Alloy steel: These sprockets provide increased hardness and wear resistance, making them suitable for heavy-duty applications.

- Stainless steel: Corrosion-resistant and commonly used in environments exposed to moisture or chemicals, stainless steel sprockets are highly valued.

Manufacturing Process

The production of our Double Pitch Sprockets follows a detailed manufacturing process to ensure high quality:

- Raw material preparation: Selected materials are meticulously prepared for manufacturing.

- Forging or casting: Sprocket blanks are formed using either forging or casting methods.

- Machining: The blanks undergo precision machining to achieve desired dimensions and tooth profiles.

- Gear hobbing: The teeth of the sprocket are cut with a gear hobbing machine.

- Heat treatment: Sprockets are heat-treated to improve hardness and mechanical properties.

- Surface treatment: Various treatments, such as plating or painting, enhance corrosion resistance and aesthetics.

- Quality inspection: Each sprocket undergoes rigorous quality checks to ensure compliance with industry standards.

Customization Services

We provide a range of customization services for our sprockets:

- Material selection: Customers can choose the material that best meets their specific application needs.

- Tooth profile design: Customizable tooth profiles are available to optimize performance and ensure compatibility with the mating chain.

- Bore diameter and keyway: We offer options to customize bore diameters and keyways for various shaft sizes and coupling methods.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, a leading manufacturer specializing in high-quality sprockets. Our range includes the NK2040RB Double Pitch Sprocket, which is designed to provide enhanced performance and durability for various applications. This sprocket is engineered to ensure a smooth operation, reducing wear and extending the life of your machinery.

In addition to our standard sprockets, we offer custom solutions tailored to meet specific customer requirements. We welcome all clients to bring their designs and samples for non-standard customization. Our dedicated team is committed to providing exceptional products and services to satisfy your needs.

Additional information

| Edited by | Sylvia |

|---|