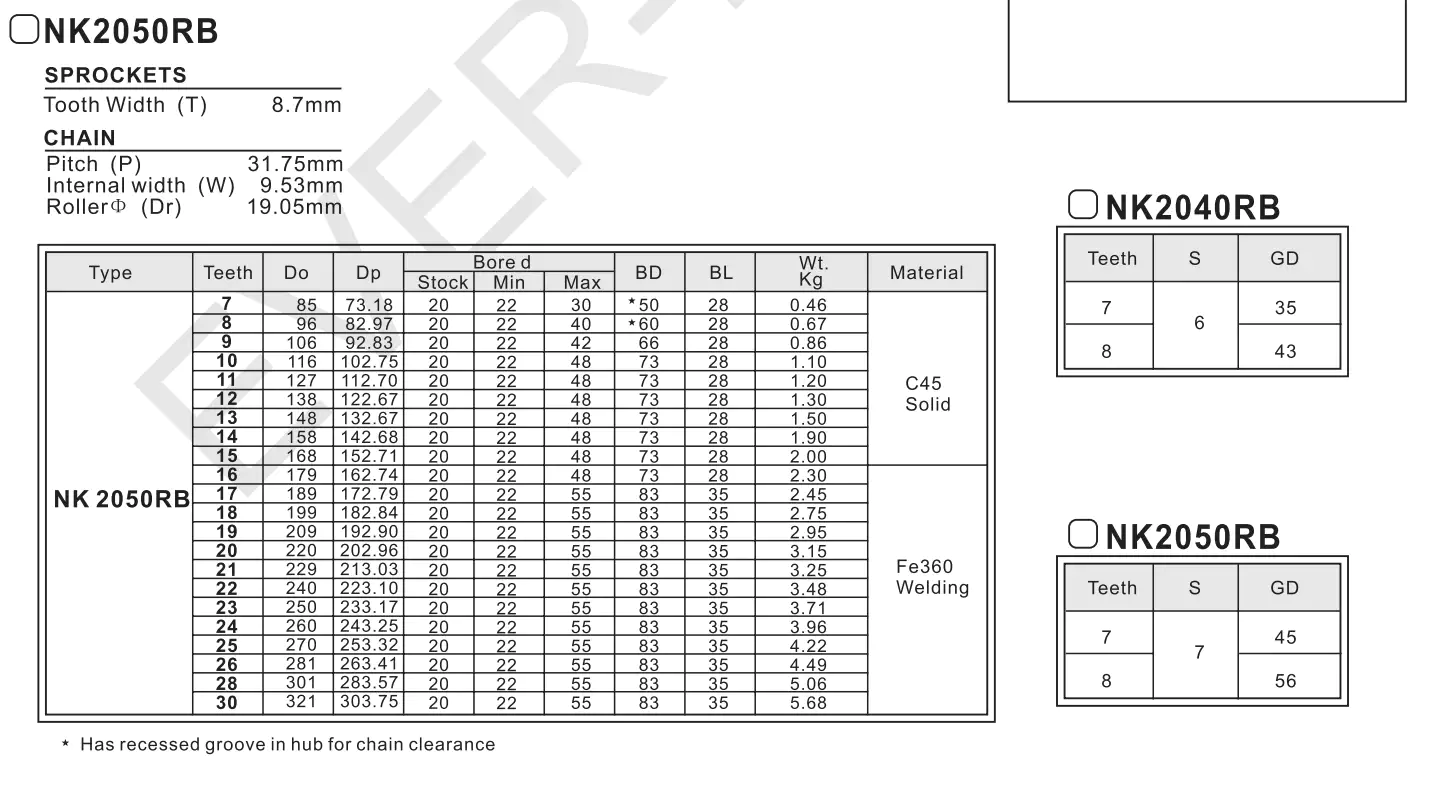

Specifications of NK2050RB Double Pitch Sprocket

The NK2050RB Double Pitch Sprocket is a type of sprocket utilized in power transmission systems, specifically designed to work with a double pitch chain. Double pitch sprockets present various advantages over standard sprockets, such as increased tooth spacing, enhanced load capacity, and smoother operation.

Definition and Basic Structure

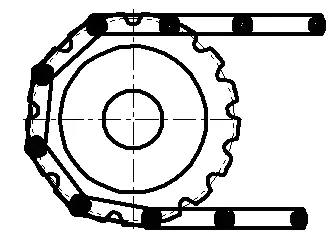

- Definition: A double pitch sprocket features a larger tooth spacing compared to a standard sprocket, designed to operate with a double pitch chain that has twice the pitch of a standard chain.

- Basic structure: This type of sprocket consists of a hub, spokes, and teeth, with the teeth being spaced further apart to accommodate the larger rollers of a double pitch chain.

Main Features

- Larger tooth spacing: The increased spacing allows for a wider chain, facilitating greater power transmission.

- Higher load capacity: The larger rollers of a double pitch chain enable a higher load capacity than a standard chain.

- Smooth operation: The design of double pitch sprockets features a larger tooth profile, leading to smoother operation and reduced noise levels.

Materials

Double pitch sprockets can be manufactured from various materials, including carbon steel, alloy steel, and stainless steel, with the material choice depending on the specific application.

- Carbon steel: A popular option for lower-load applications where budget is a consideration.

- Alloy steel: Provides enhanced strength and durability, making it suitable for high-load applications.

- Stainless steel: Offers excellent corrosion resistance, ideal for harsh environments.

Manufacturing Process

The production of our double pitch sprockets follows a precise manufacturing process consisting of several steps:

- Raw material preparation: The appropriate steel grade is chosen and prepared for forging or casting.

- Forging or casting: The sprocket blank is created through either forging or casting methods.

- Machining: The sprocket blank is machined to the required dimensions and tooth profile.

- Tooth rolling: Teeth formation is achieved with a specialized rolling machine.

- Heat treatment: The sprocket undergoes heat treatment to enhance its strength and durability.

- Surface treatment: A coating or plating is applied to protect against corrosion.

- Quality inspection: The finished sprocket is subjected to stringent quality checks to ensure it meets our standards.

Customization Services

We provide various customization services to ensure you receive the precise double pitch sprocket you require:

- Material selection: Assistance in choosing the optimal material for your specific application.

- Tooth profile design: Custom design of the tooth profile to match your unique specifications.

- Bore and keyway: Customization of the bore and keyway to fit your shaft.

Sprockets Supplier in Australia

GBC serves as the Australian sales agent for Ever-power Group, providing high-quality sprockets and related products to meet various industrial needs. One of our featured products is the NK2050RB Double Pitch Sprocket, designed for enhanced durability and efficiency in power transmission systems. Our sprockets are manufactured using advanced techniques and materials, ensuring reliability and performance in demanding applications.

In addition to standard sprockets, we also offer custom solutions tailored to meet the specific requirements of our clients. We encourage customers to bring their designs and samples for bespoke production. Your unique needs are our priority, and we are dedicated to delivering exceptional products and services to support your operations.

Additional information

| Edited by | Sylvia |

|---|