Track Drive for Crawler Cranes

The Track Drive Planetary Gearbox for Crawler Cranes is designed to provide efficient power transfer and torque multiplication, enhancing the crane’s mobility and stability on uneven terrain. This gearbox enables precise control of movement, ensuring that crawler cranes can navigate challenging job sites with ease and reliability.

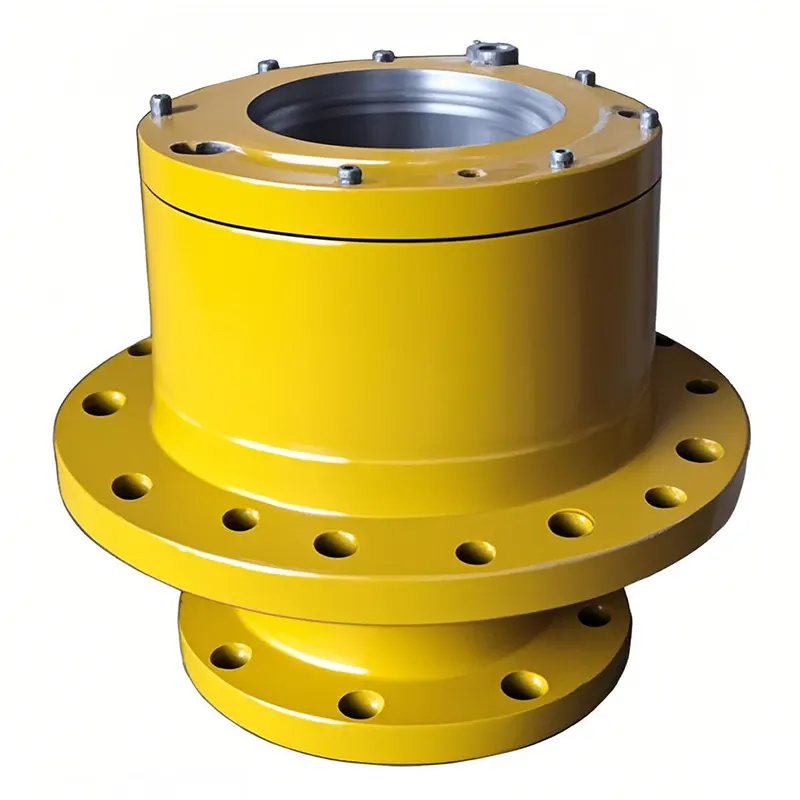

Track Drive Planetary Gearbox for Crawler Cranes

This innovative gearbox provides superior torque and efficiency, ensuring reliable performance for crawler cranes in demanding applications.

| Feature | Description |

|---|---|

| Outp |