Track Drive for Tunnel Boring Machines

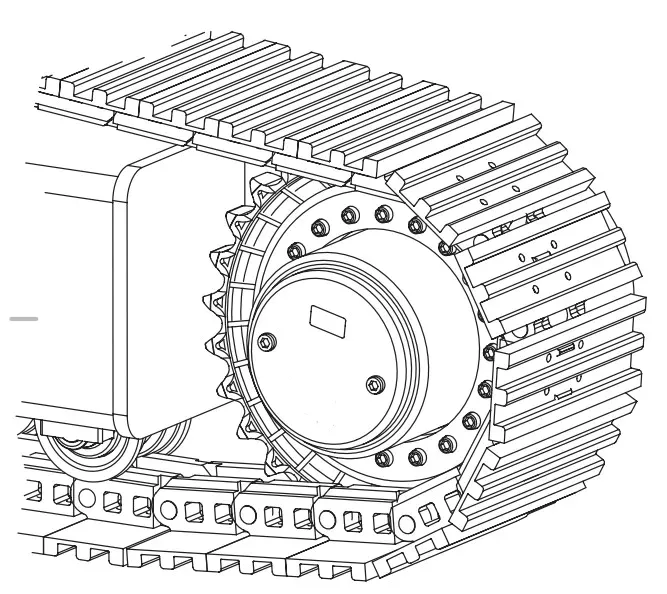

The Track Drive Planetary Gearbox is an essential component in Tunnel Boring Machines (TBMs), providing robust torque and precise control for the movement of the machine. This gearbox enables the TBM to navigate through various geological conditions efficiently, ensuring reliable traction and stability during tunnel excavation processes.

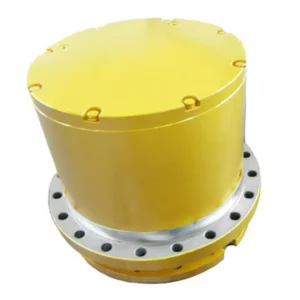

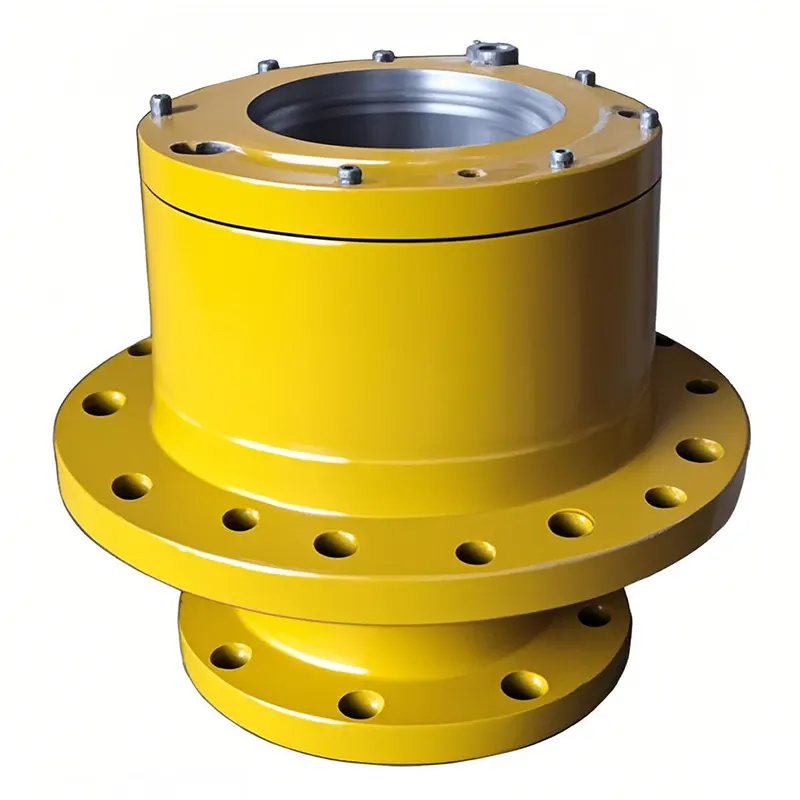

Track Drive Planetary Gearbox for Tunnel Boring Machines

The Track Drive Planetary Gearbox is engineered for high efficiency and reliability, making it ideal for the demanding conditions of tunnel boring operations.

| Feature | Description |

|---|---|

| Output Torque Range | 1000-450000 N¡¤m |

| Gear Ratios | i = 5.3 - 500 |

| Support | The gearbox has rotating housing flanges to fit tracks |

| Applicable Motors | Axial piston hydraulic motors, hydraulic orbit motors, or others |

| Hydraulic Motor Options | Pressure relief valve, overcenter valve |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake |

| High Torque and Load Capacities | Designed to carry equipment over the roughest and steepest terrain |

| Motor Mounting | Designed to allow mounting of plug-in motors |

| Compact Design | Integral multi-disc parking brakes, while still keeping the drive compact |

| Material | Steel structure |

| Easy Maintenance | Filling and draining openings are reasonably located for easy reach |

| Front Mechanical Seal | Designed specifically for earth-moving machines |

| Compatibility | Technical data and installation dimensions of EP400T Series gearbox are the same as those of Rexroth GFT¡T Series and Bonfiglioli 700C Series, allowing interchangeability |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m.) |

| EP400T1 | 1300 | 6.09 | 1000 | 130 |

| EP401T1 | 2000 | 6.2 | 1000 | 270 |

| EP402T2 | 5000 | 12.4-37.1 | 3500 | - |

| EP403T2 | 7000 | 15.4-40 | 3500 | 270 |

| EP405T | 10000 | 20-80 | 3500 | 270 |

| EP405.4T | 11000 | 26-57 | 3500 | 280 |

| EP406AT | 17000 | 23-220 | 3500 | 430 |

| EP406T | 18000 | 28-140 | 3500 | 430 |

| EP406BT3 | 24000 | 63-136 | 3500 | 430 |

| EP407AT | 26000 | 38-136 | 3500 | 430-530 |

| EP407T3 | 36000 | 63-136 | 3500 | 530 |

| EP410T3 | 50000 | 62-177 | 3500 | 530 |

| EP413T3 | 60000 | 86-172 | 3500 | 610 |

| EP414T3 | 80000 | 76-186 | 3500 | 1200 |

| EP415T3 | 110000 | 81-215 | 3000 | 1200 |

| EP416T3 | 160000 | 87-255 | 3000 | 2000 |

| EP417T3 | 220000 | 123-365 | 3000 | 2000 |

| EP418T3 | 270000 | 166-364 | 3000 | 2000 |

| EP419T3 | 330000 | 161-306 | 2500 | 3000 |

| EP420T4 | 450000 | 296-421 | 2500 | 1700 |

Working Principle of Track Drive Planetary Gearbox for Tunnel Boring Machines

The planetary gear system consists of a sun gear, planet gears, a ring gear, and a planet carrier. The sun gear, driven by the input, rotates and causes the planet gears to orbit around it, engaging with the inner teeth of the ring gear. This arrangement allows the planet carrier to rotate, translating the input motion into output motion. By adjusting the gear ratios, the system achieves a reduction in speed while simultaneously increasing torque. This efficiency is vital for the demanding operations of tunnel boring machines.

Space Efficiency in Track Drive Planetary Gearboxes for Bulldozers

Space efficiency is crucial for track vehicles like bulldozers, as it directly impacts maneuverability and overall performance. The compact design of track drive planetary gearboxes allows for a significant reduction in size compared to traditional gearboxes. This reduction not only saves valuable space within the vehicle but also contributes to a lower center of gravity, enhancing stability and traction. Furthermore, the efficient layout of these gearboxes can lead to improved power output and reduced weight, making them an optimal choice for heavy-duty applications. Overall, maximizing space efficiency is essential for the operational effectiveness of bulldozers.

Lubrication and Cooling of Track Drive Planetary Gearbox

The Track Drive Planetary Gearbox for Tunnel Boring Machines operates under heavy loads and low-speed conditions, necessitating effective lubrication to minimize wear and friction. Adequate lubrication ensures smooth operation, prolonging the gearbox's lifespan. Additionally, proper cooling design is critical, as it dissipates heat generated during operation. Excessive temperatures can lead to oil degradation and component failure. Therefore, a robust lubrication and cooling system is vital for optimizing performance and durability in demanding tunneling environments.

Track Drive Planetary Gearbox for Tunnel Boring Machines

The track drive planetary gearbox plays a crucial role in tunnel boring machines by providing the necessary torque, speed, and durability. These gearboxes must handle high torque to penetrate tough geological formations while maintaining optimal speed for efficient operation. Durability is paramount, ensuring reliable performance under extreme conditions and extended use.

Understanding the Requirements of Gearbox Performance

Customization Available for Track Drive

Our Track Drive Planetary Gearbox for Tunnel Boring Machines is not only available as a standard product, but we also offer customization options to meet your specific needs.

| Required Information | Description |

|---|---|

| 1. Power or Torque | Please specify the required power or torque for your application. |

| 2. Gear Ratio | Provide the desired gear ratio for optimal performance. |

| 3. Speed | Indicate the required operational speed. |

| 4. Input Type | Specify the type of input required. |

| 5. Output Type | Detail the output type (spline/hollow/solid, etc.). |

| 6. External or Radial Forces | Indicate if there are any external or radial forces on the input or output end. |

| 7. Operating Temperature | Provide the expected working temperature range. |

| 8. Lifespan Requirements | Specify any lifespan requirements for your operation. |

| 9. Special Requirements | List any special requirements, such as continuous operation or impact considerations. |

Track Drive Supplier

GBC is the Australian sales agent for Ever-power Group, providing top-quality solutions in the industry. Our Track Drive Planetary Gearbox for Tunnel Boring Machines embodies core value through its durability, efficiency, and precision engineering. These gearboxes are essential for optimizing performance in demanding tunnel construction environments.

We invite our esteemed customers to customize and purchase our advanced gearboxes, ensuring that your machinery operates at peak efficiency. Enhance your projects with our reliable solutions today!

Additional information

| Edited by | Sylvia |

|---|

The Track Drive Planetary Gearbox is an essential component in Tunnel Boring Machines (TBMs), providing robust torque and precise control for the movement of the machine. This gearbox enables the TBM to navigate through various geological conditions efficiently, ensuring reliable traction and stability during tunnel excavation processes.