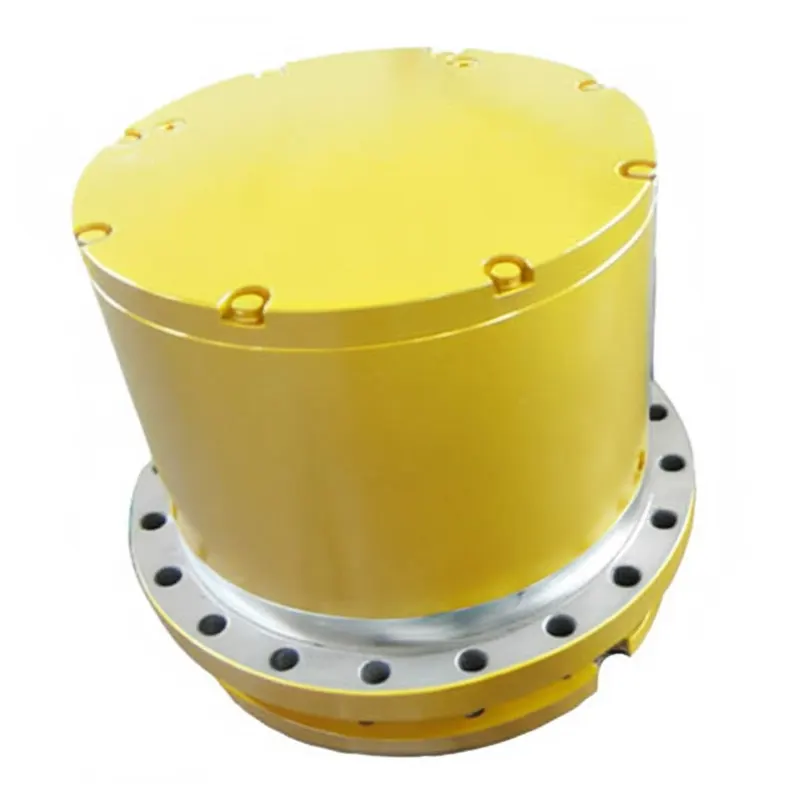

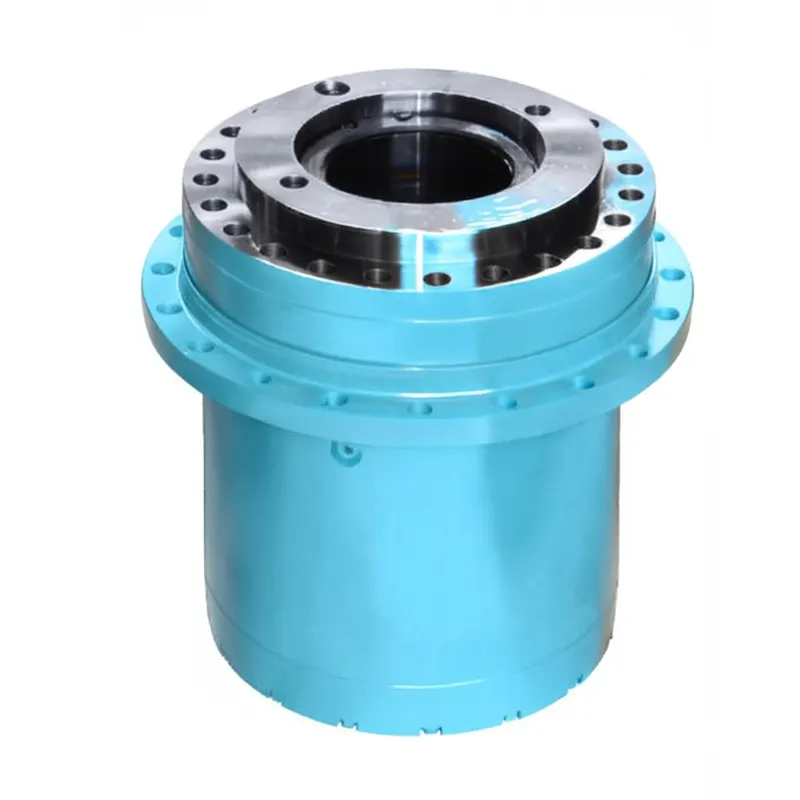

Winch Drive for Tower Cranes

The Winch Drive Planetary Gearbox for Tower Cranes is a vital component designed to optimize the performance of hoisting systems. This gearbox efficiently transmits power and increases torque, allowing for precise control and lifting capabilities in tower cranes, ensuring safe and effective material handling on construction sites.

Winch Drive Planetary Gearbox for Tower Cranes

The Winch Drive Planetary Gearbox for Tower Cranes offers exceptional efficiency and durability, designed to handle heavy loads with ease. Its compact design and high torque output make it ideal for enhancing the performance and reliability of tower cranes in various applications.

Specifications

- Gear ratio: customizable from 10:1 to 100:1

- Input power: up to 300 kW

- Output torque: up to 150,000 Nm

- Efficiency: over 95% under standard operating conditions

- Operating temperature range: -40°C to 80°C

| Specification | Details |

|---|---|

| Output torque range | 1000-280000 N.m |

| Gear ratios | i=5.3-400 |

| Support | The gearbox has rotating housing flanges to fit winch |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve on request |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake on request |

| Performance figures | Refer to FEM standards, class M5 (T5-L2) for output max. speeds of 25 rpm |

| Compatibility | Technical data and installation dimensions of the EP400W Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 800 Series, so these three can be used interchangeably |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP400W1 | 870 | 6.09 | 1000 | 130 |

| EP401W1 | 1300 | 6.2 | 1000 | 270 |

| EP402W2 | 4000 | 12.4-37.1 | 3500 | - |

| EP403W2 | 4000 | 15.4-40 | 3500 | 270 |

| EP405W | 7000 | 20-80 | 3500 | 270 |

| EP405.4W | 5500 | 26-57 | 3500 | 280 |

| EP406AW | 12500 | 23-220 | 3500 | 430 |

| EP406W | 13000 | 28-140 | 3500 | 430 |

| EP406BW3 | 17500 | 63-136 | 3500 | 430 |

| EP407AW | 18000 | 38-136 | 3500 | 430-530 |

| EP407W3 | 26000 | 63-136 | 3500 | 530 |

| EP410W3 | 37500 | 62-177 | 3500 | 530 |

| EP413W3 | 42500 | 86-172 | 3500 | 610 |

| EP414W3 | 67000 | 76-186 | 3500 | 1200 |

| EP415W3 | 100000 | 81-215 | 3000 | 1200 |

| EP416W3 | 140000 | 87-255 | 3000 | 2000 |

| EP417W3 | 200000 | 123-365 | 3000 | 2000 |

| EP419W3 | 275000 | 161-306 | 2500 | 3000 |

How does the Winch Drive Planetary Gearbox for Tower Cranes Work?

The Winch Drive Planetary Gearbox operates through a series of gears arranged in a planetary system. At its core, the central sun gear drives multiple planetary gears that rotate around it, which are connected to a ring gear. This arrangement allows for increased torque output and compact size, essential for tower cranes. As the motor turns the sun gear, the planetary gears transfer power to the ring gear, effectively amplifying the force needed to lift heavy loads. The gearbox's robust structure ensures durability and efficiency in demanding construction environments.

Choosing the Right Gear Ratio for Winch Drive Planetary Gearbox

The Winch Drive Planetary Gearbox for Tower Cranes is crucial for optimizing performance based on load and speed requirements. Selecting the appropriate gear ratio is essential for achieving the desired torque and speed. A lower gear ratio increases torque, making it suitable for heavy loads, while a higher ratio enhances speed, ideal for lighter loads. It is important to evaluate the specific operational demands to ensure efficiency and reliability. Proper gear ratio selection not only improves performance but also extends the lifespan of the gearbox.

How to Choose a Winch Drive Planetary Gearbox for Tower Cranes

When selecting a Winch Drive Planetary Gearbox for tower cranes, several key factors must be considered. First, evaluate the power or torque requirements of your application. Next, determine the gear ratio needed for optimal performance and the operating speed. Consider the input type and output type (spline, hollow, solid) to ensure compatibility. Assess if there are external or radial forces acting on the input or output ends. Additionally, take into account the operating temperature conditions and required lifespan. Finally, identify any special requirements, such as continuous operation or shock loads, to ensure optimal gearbox performance.

Winch Drive Planetary Gearbox for Tower Cranes

To determine if a winch drive planetary gearbox for tower cranes is overloaded, monitor several key indicators. First, listen for unusual noises such as grinding or clattering, which may indicate excessive strain. Second, check the temperature of the gearbox; a significant rise beyond normal operating levels suggests potential overload. Lastly, inspect for signs of wear or damage, which can be exacerbated by overload conditions. Regular maintenance and monitoring are essential to ensure optimal performance.

Signs of Gearbox Overload

- Unusual noises during operation

- Excessive heat generation

- Visible wear and tear on components

- Inconsistent performance levels

Winch Planetary Gearbox Supplier

GBC is the Australian sales agent for Ever-power Group, providing top-quality gear solutions for various applications. The Winch Drive Planetary Gearbox for Tower Cranes plays an essential role in enhancing efficiency and reliability in lifting operations. Its advanced design ensures smooth power transmission and increased torque, making it indispensable for construction projects. We invite all customers to customize and purchase our planetary gearboxes to meet their unique needs and experience the exceptional performance that GBC and Ever-power Group offer.

Additional information

| Edited by | Sylvia |

|---|

The Winch Drive Planetary Gearbox for Tower Cranes is a vital component designed to optimize the performance of hoisting systems. This gearbox efficiently transmits power and increases torque, allowing for precise control and lifting capabilities in tower cranes, ensuring safe and effective material handling on construction sites.