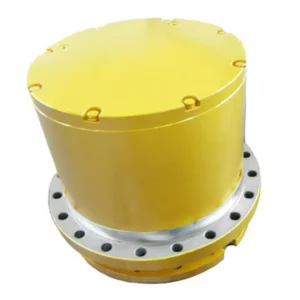

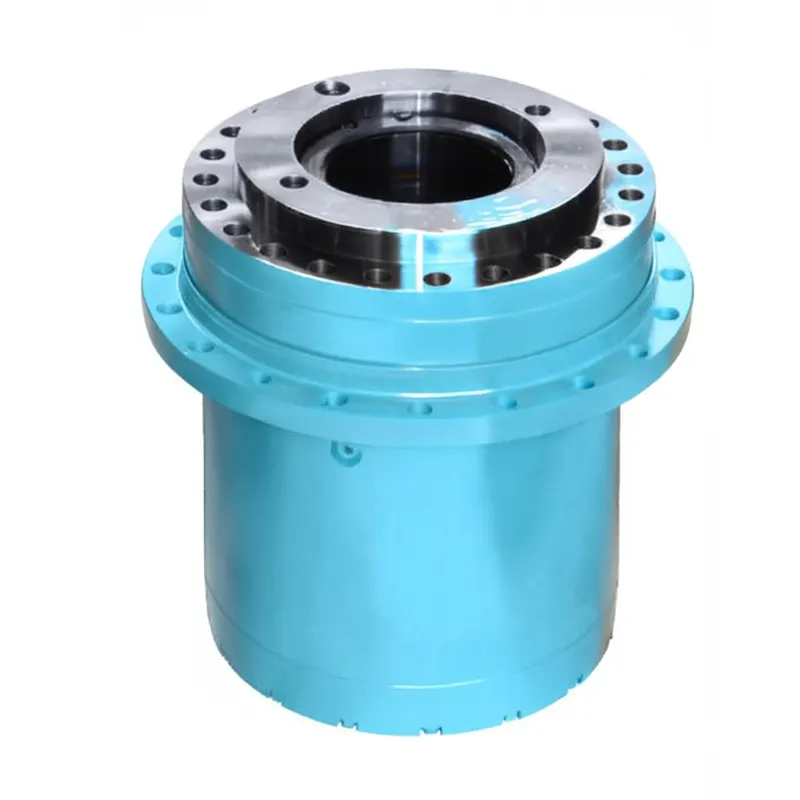

Winch Drive for Oil Drilling Winches

The Winch Drive Planetary Gearbox for Oil Drilling Winches is a high-efficiency mechanical system designed to transfer power from the motor to the winch. It allows for precise control and enhanced torque, making it essential for lifting and lowering operations in oil drilling applications, ensuring reliability and performance in demanding environments.

Winch Drive Planetary Gearbox for Oil Drilling Winches

The Winch Drive Planetary Gearbox is engineered to provide exceptional torque and efficiency, making it ideal for heavy-duty oil drilling applications. Its compact design and robust construction ensure reliable performance even in the most demanding environments.

Specifications

- Gear Ratio: Customized options available

- Max Input Speed: 3000 RPM

- Output Torque: Up to 10000 Nm

- Material: High-strength alloy steel

- Weight: Varies based on configuration

| Specification | Details |

|---|---|

| Output torque range | 1000-280000 N.m |

| Gear ratios | i=5.3-400 |

| Support | The gearbox has rotating housing flanges to fit winch |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve on request |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake on request |

| Performance figures | Refer to FEM standards, class M5 (T5-L2) for output max. speeds of 25 rpm |

| Compatibility | Technical data and installation dimensions of the EP400W Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 800 Series, so these three can be used interchangeably |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP400W1 | 870 | 6.09 | 1000 | 130 |

| EP401W1 | 1300 | 6.2 | 1000 | 270 |

| EP402W2 | 4000 | 12.4-37.1 | 3500 | - |

| EP403W2 | 4000 | 15.4-40 | 3500 | 270 |

| EP405W | 7000 | 20-80 | 3500 | 270 |

| EP405.4W | 5500 | 26-57 | 3500 | 280 |

| EP406AW | 12500 | 23-220 | 3500 | 430 |

| EP406W | 13000 | 28-140 | 3500 | 430 |

| EP406BW3 | 17500 | 63-136 | 3500 | 430 |

| EP407AW | 18000 | 38-136 | 3500 | 430-530 |

| EP407W3 | 26000 | 63-136 | 3500 | 530 |

| EP410W3 | 37500 | 62-177 | 3500 | 530 |

| EP413W3 | 42500 | 86-172 | 3500 | 610 |

| EP414W3 | 67000 | 76-186 | 3500 | 1200 |

| EP415W3 | 100000 | 81-215 | 3000 | 1200 |

| EP416W3 | 140000 | 87-255 | 3000 | 2000 |

| EP417W3 | 200000 | 123-365 | 3000 | 2000 |

| EP419W3 | 275000 | 161-306 | 2500 | 3000 |

How does the Winch Drive Planetary Gearbox for Oil Drilling Winches Work?

The Winch Drive Planetary Gearbox operates through a series of gears that distribute torque efficiently. Its basic structure includes a sun gear, planet gears, and a ring gear, all enclosed within a housing. When the sun gear rotates, it causes the planet gears to revolve around it, which in turn drives the ring gear. This design allows for high torque output while maintaining a compact footprint, making it ideal for oil drilling applications. The gearbox ensures smooth operation and enhances the performance of winches in challenging environments.

Determining Maximum Torque Capacity of Winch Drive Planetary Gearbox

To determine the maximum torque capacity of the Winch Drive Planetary Gearbox used in oil drilling winches, several factors must be considered. First, calculate the gear ratio and input speed of the gearbox. Using the formula: Maximum Torque = (Input Power x 60) / (2π x Input Speed), you can derive the maximum torque. Additionally, material properties and design factors, including safety margins, should be assessed. It's crucial to consult manufacturer specifications and engineering guidelines to ensure the gearbox can handle the required load efficiently and safely.

How to Choose Winch Drive Planetary Gearbox for Oil Drilling Winches

When selecting a winch drive planetary gearbox for oil drilling applications, several factors must be considered. First, determine the power or torque requirements to ensure the gearbox can handle the load. The gear ratio is crucial for achieving the desired speed and torque. Evaluate the input and output types, including spline, hollow, or solid configurations. Consider whether external forces or radial loads will act on the input or output ends. Additionally, assess the working temperature and the expected lifespan of the gearbox. Finally, account for any special requirements, such as continuous operation or shock loads, to ensure optimal performance.

Winch Drive Planetary Gearbox for Oil Drilling Winches

To determine whether a planetary gearbox is overloaded, operators should monitor several indicators. Key signs include abnormal noises, overheating, and excessive vibrations during operation. Additionally, if the gearbox's output speed significantly drops or if it experiences difficulty in starting, these may indicate that the load exceeds the gearbox's rated capacity. Regular maintenance checks and performance monitoring can help in early detection of overload conditions.

Indicators of Overload in Gearboxes

- Unusual noises during operation.

- Overheating of the gearbox.

- Increased vibration levels.

- Significant drops in output speed.

- Struggles during startup.

Winch Planetary Gearbox Supplier

GBC is the Australian sales agent for Ever-power Group, specializing in high-quality winch solutions. The Winch Drive Planetary Gearbox for Oil Drilling Winches plays a crucial role in enhancing the efficiency and reliability of drilling operations. Its design ensures optimal torque transmission and durability, making it an essential component for any drilling rig. We encourage our valued customers to consider customizing and purchasing these vital gearboxes to meet their specific operational needs and improve productivity.

Additional information

| Edited by | Sylvia |

|---|

The Winch Drive Planetary Gearbox for Oil Drilling Winches is a high-efficiency mechanical system designed to transfer power from the motor to the winch. It allows for precise control and enhanced torque, making it essential for lifting and lowering operations in oil drilling applications, ensuring reliability and performance in demanding environments.