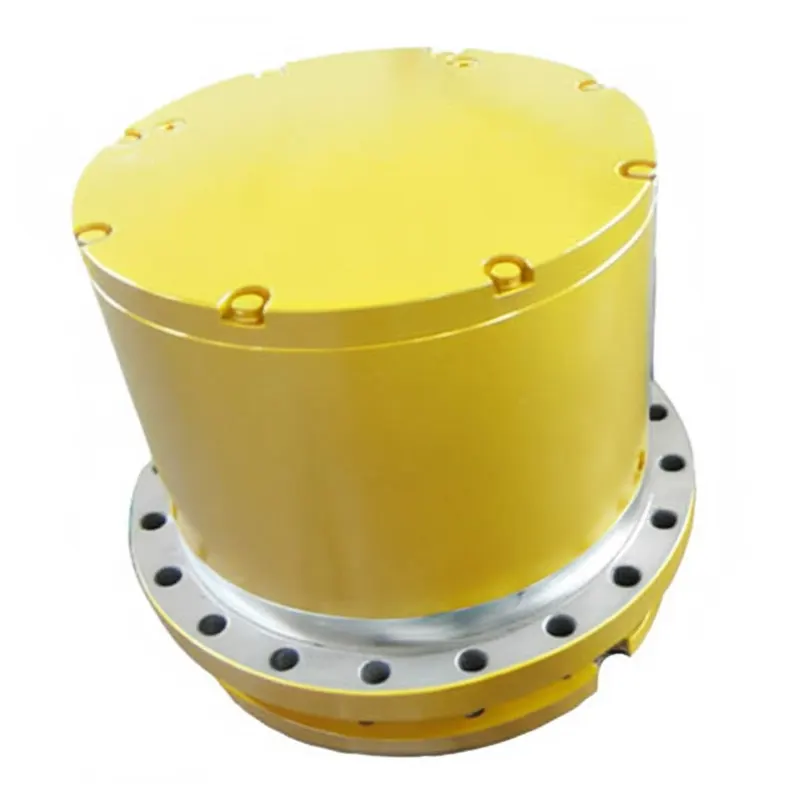

Winch Drive for Wind Turbine Installation Equipment

The Winch Drive Planetary Gearbox is designed specifically for wind turbine installation equipment. This gearbox provides high torque and efficiency, enabling smooth operation of winch systems. Its planetary design allows for compact size while delivering reliable power transmission, essential for the precise positioning and lifting of heavy turbine components.

Winch Drive Planetary Gearbox for Wind Turbine Installation Equipment

The Winch Drive Planetary Gearbox is designed for high efficiency and reliability in wind turbine installation equipment. Its compact design and robust construction ensure optimal performance in demanding environments, reducing downtime and maintenance costs.

| Specification | Details |

|---|---|

| Output torque range | 1000-280000 N.m |

| Gear ratios | i=5.3-400 |

| Support | The gearbox has rotating housing flanges to fit winch |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve on request |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake on request |

| Performance figures | Refer to FEM standards, class M5 (T5-L2) for output max. speeds of 25 rpm |

| Compatibility | Technical data and installation dimensions of the EP400W Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 800 Series, so these three can be used interchangeably |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP400W1 | 870 | 6.09 | 1000 | 130 |

| EP401W1 | 1300 | 6.2 | 1000 | 270 |

| EP402W2 | 4000 | 12.4-37.1 | 3500 | - |

| EP403W2 | 4000 | 15.4-40 | 3500 | 270 |

| EP405W | 7000 | 20-80 | 3500 | 270 |

| EP405.4W | 5500 | 26-57 | 3500 | 280 |

| EP406AW | 12500 | 23-220 | 3500 | 430 |

| EP406W | 13000 | 28-140 | 3500 | 430 |

| EP406BW3 | 17500 | 63-136 | 3500 | 430 |

| EP407AW | 18000 | 38-136 | 3500 | 430-530 |

| EP407W3 | 26000 | 63-136 | 3500 | 530 |

| EP410W3 | 37500 | 62-177 | 3500 | 530 |

| EP413W3 | 42500 | 86-172 | 3500 | 610 |

| EP414W3 | 67000 | 76-186 | 3500 | 1200 |

| EP415W3 | 100000 | 81-215 | 3000 | 1200 |

| EP416W3 | 140000 | 87-255 | 3000 | 2000 |

| EP417W3 | 200000 | 123-365 | 3000 | 2000 |

| EP419W3 | 275000 | 161-306 | 2500 | 3000 |

How does the Winch Drive Planetary Gearbox for Wind Turbine Installation Equipment Work?

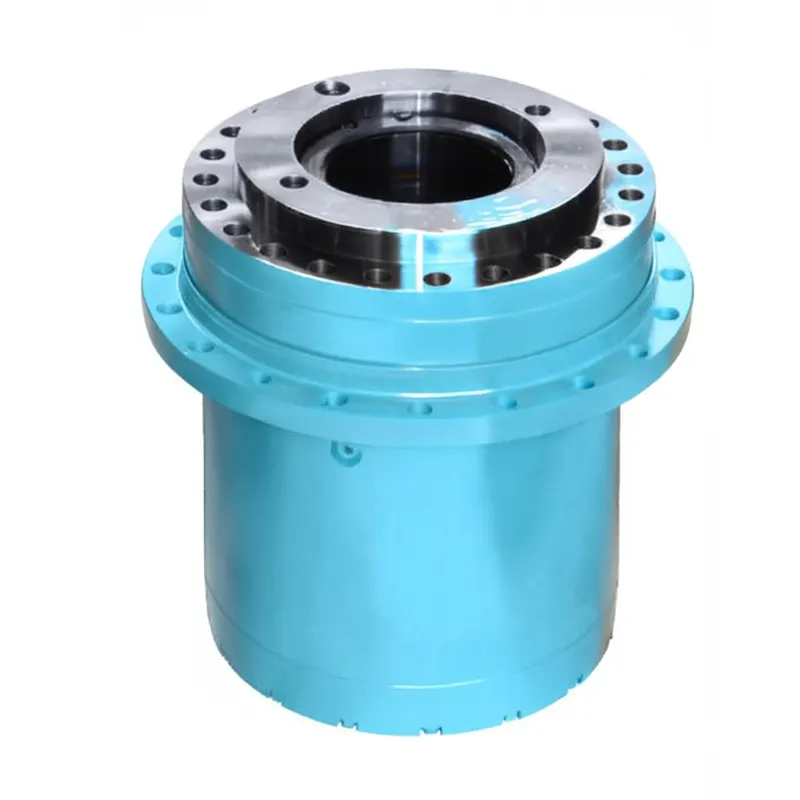

The Winch Drive Planetary Gearbox is designed to efficiently transmit power in wind turbine installation equipment. It consists of a central sun gear, multiple planet gears, and an outer ring gear, creating a compact and robust structure. As the sun gear rotates, the planet gears revolve around it, transferring motion to the ring gear. This planetary arrangement allows for high torque output while minimizing size and weight, making it ideal for heavy-duty lifting tasks in wind turbine installations.

Determining Maximum Torque Capacity of Winch Drive Planetary Gearbox

To ascertain the maximum torque capacity of the Winch Drive Planetary Gearbox designed for wind turbine installation, several factors must be evaluated. First, consider the gearbox's material strength and design specifications, which define its load-bearing capabilities. Next, analyze the gear ratios, as they influence the torque multiplication effect. Additionally, assess the operational conditions, including load variations and environmental factors. Finally, consult the manufacturer's guidelines and perform calculations based on the gearbox's mechanical properties to ensure it meets the required torque limits without risking failure.

How to Choose a Winch Drive Planetary Gearbox for Wind Turbine Installation Equipment

When selecting a winch drive planetary gearbox, consider the following factors: First, evaluate the power or torque requirements to ensure compatibility with your application. Next, determine the gear ratio and operational speed needed for optimal performance. Assess the input type and output configuration, such as spline, hollow, or solid shaft options. It's essential to check for external or radial loads on the input or output ends. Additionally, review the working temperature, lifespan requirements, and any special demands, like continuous operation or shock resistance, to ensure the gearbox meets your specific needs.

Winch Drive Planetary Gearbox for Wind Turbine Installation Equipment

To determine if a winch drive planetary gearbox is overloaded, observe the following indicators: monitor the gearbox temperature; excessive heat can signify overload. Additionally, check for unusual noises or vibrations during operation, which may indicate stress on the components. Lastly, inspect for signs of wear or damage on the gear teeth and housing. Regular maintenance and monitoring are essential to prevent overload and ensure the longevity of the gearbox.

Signs of Gearbox Overload

- Increased operating temperature

- Unusual noises or vibrations

- Visible wear on gear teeth

- Frequent tripping of overload protection systems

Winch Planetary Gearbox Supplier

GBC is the Australian sales agent for Ever-power Group, providing top-quality winch drive planetary gearboxes. The Winch Drive Planetary Gearbox is crucial for wind turbine installation equipment, offering enhanced torque and efficiency while ensuring reliability in demanding conditions. These gearboxes are designed to withstand the rigors of heavy-duty applications, making them essential for the smooth operation of wind energy projects.

We encourage all customers to customize and purchase our winch drive planetary gearboxes, tailored to meet your specific requirements. Invest in quality that delivers performance and durability.

Additional information

| Edited by | Sylvia |

|---|

The Winch Drive Planetary Gearbox is designed specifically for wind turbine installation equipment. This gearbox provides high torque and efficiency, enabling smooth operation of winch systems. Its planetary design allows for compact size while delivering reliable power transmission, essential for the precise positioning and lifting of heavy turbine components.