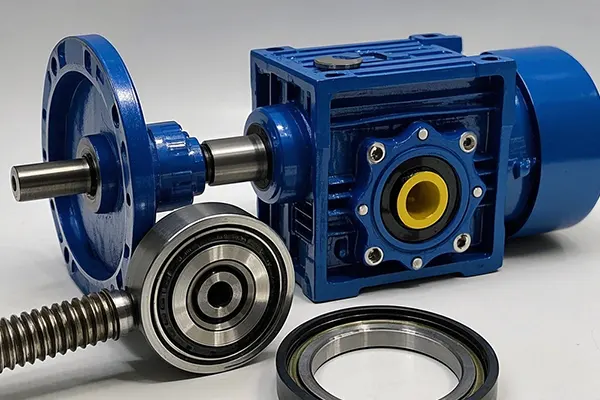

Worm Gearbox Solutions for All Industries

Explore our high-quality worm reducer gearboxes designed for precision, durability, and efficiency across diverse applications.

Worm Gearbox for Sale

Our worm drive gearboxes are engineered to meet the needs of various industries, offering reliable performance, high torque, and compact designs. Browse by application to find the perfect solution for your equipment.

Worm Gearboxes for Industrial Applications

Robust and versatile gearboxes for heavy-duty industrial use.

Worm Gearbox for Conveyor Systems

- Features: High torque, durable housing, self-locking option.

- Function: Drives belts to transport materials in factories.

Worm Gearbox for Mixers

- Features: Smooth operation, high reduction ratio, wear-resistant materials.

- Function: Powers mixing blades for uniform blending in processing.

Worm Gearbox for Packaging Machinery

- Features: Compact size, precise speed control, low maintenance.

- Function: Operates sealing or labeling components in packaging lines.

Worm Gearbox for Winches

- Features: Strong load capacity, self-locking, corrosion-resistant finish.

- Function: Provides lifting power for industrial hoisting equipment.

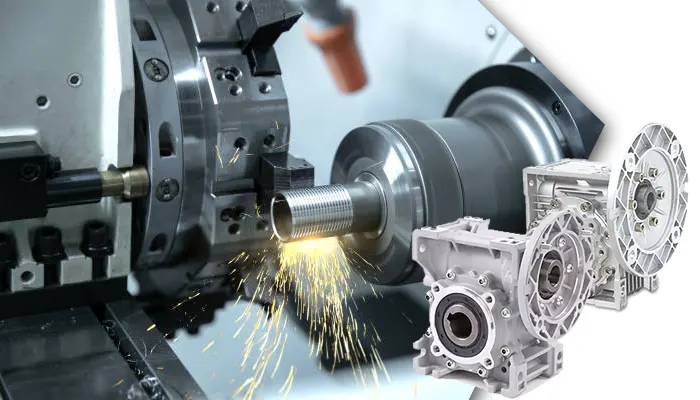

Worm Gearbox for Machine Tools

- Features: High precision, adjustable speed, robust construction.

- Function: Controls precise movements in milling or cutting machines.

Worm Speed Reducers for Agricultural Equipment

Durable gearboxes designed for outdoor and rugged use.

Worm Speed Reducer for Irrigation Equipment

- Features: Corrosion-resistant, high torque, weatherproof.

- Function: Rotates sprinklers for even watering.

Worm Speed Reducer for Seeders

- Features: Precise control, durable, dust-resistant.

- Function: Dispenses seeds at controlled rates.

Worm Speed Reducer for Harvesters

- Features: Heavy-duty, shock-resistant, high load capacity.

- Function: Drives cutting or collecting parts in crops.

Worm Speed Reducer for Greenhouse Shutter Machines

- Features: Compact, reliable, weather-resistant.

- Function: Raises/lowers vents for climate control.

Worm Speed Reducer for Feed Mixers

- Features: High torque, sturdy, low maintenance.

- Function: Blends animal feed uniformly.

Worm Drive Gearboxes for Construction Machinery

Heavy-duty gearboxes for construction reliability.

Worm Drive Gearbox for Construction Elevators

- Features: Self-locking, high load capacity, rugged design.

- Function: Lifts materials or workers to heights.

Worm Drive Gearbox for Concrete Mixers

- Features: High torque, wear-resistant, stable operation.

- Function: Rotates drums to mix concrete.

Worm Drive Gearbox for Tower Cranes

- Features: Strong build, precise control, high durability.

- Function: Adjusts crane arms for lifting tasks.

Worm Drive Gearbox for Electric Rolling Doors

- Features: Smooth motion, reliable, easy to install.

- Function: Opens/closes large doors in buildings.

Worm Drive Gearbox for Pile Drivers

- Features: Impact-resistant, high power, robust housing.

- Function: Powers pile insertion for foundations.

Worm Drive Reduction Gearboxes for Energy Solutions

Precision gearboxes for sustainable energy systems.

Worm Drive Reduction Gearbox for Solar Trackers

- Features: High precision, weatherproof, low speed operation.

- Function: Aligns panels to follow the sun.

Worm Drive Reduction Gearbox for Wind Turbines

- Features: High load capacity, durable, smooth adjustment.

- Function: Adjusts blade angles or orientation.

Worm Drive Reduction Gearbox for Hydroelectric Gate Controls

- Features: Corrosion-resistant, strong torque, reliable.

- Function: Opens/closes water flow gates.

Worm Drive Reduction Gearbox for Geothermal Pumps

- Features: Heat-resistant, steady performance, compact.

- Function: Drives pumps for heat extraction.

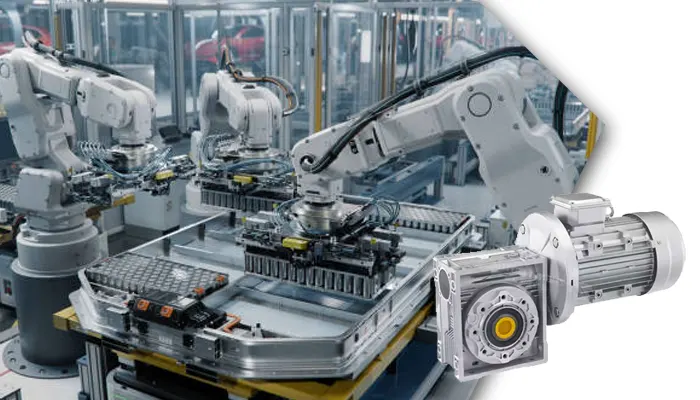

Worm Reduction Gearboxes for Precision Machinery

High-accuracy gearboxes for advanced technology applications.

Worm Reduction Gearbox for CNC Machines

- Features: Minimal backlash, high precision, sturdy build.

- Function: Ensures precise tool positioning in machining.

Worm Reduction Gearbox for Industrial Robots

- Features: High torque, compact, excellent repeatability.

- Function: Powers robotic arms for accurate tasks.

Worm Reduction Gearbox for Medical Equipment

- Features: Sterilizable materials, quiet, high reliability.

- Function: Drives components in scanners or surgical tools.

Worm Reducers for Automotive Solutions

Compact and efficient worm reducers for automotive precision.

Worm Reducer for Automotive Steering Systems

- Features: Self-locking, smooth torque delivery, compact design.

- Function: Transfers steering input to wheel movement.

Worm Reducer for Electric Seat Adjusters

- Features: Low noise, small footprint, reliable operation.

- Function: Adjusts seat position for driver comfort.

Worm Reducer for Window Lifters

- Features: Lightweight, high efficiency, durable gears.

- Function: Raises and lowers car windows smoothly.

Worm Reducer for Rearview Mirror Adjusters

- Features: Micro size, precise adjustment, low power consumption.

- Function: Fine-tunes mirror angles for visibility.

Worm Reducer for Windshield Wiper Motors

- Features: Weather-resistant, consistent speed, quiet operation.

- Function: Drives wipers for clear windshield operation.

Worm Gearmotor Features and Advantages

- Worm gearboxes can be obtained with large transmission ratios and are more compact than staggered helical gear mechanisms.

- There is line contact between the tooth surfaces of the two wheels, and its bearing capacity is much higher than that of the staggered helical gear mechanism.

- Worm transmission is equivalent to spiral transmission, multi-tooth meshing transmission, so the transmission is smooth and the noise is very small.

- Worm gear reducer has self-locking property. When the lead Angle of the worm is less than the equivalent friction Angle between the meshing gear teeth, the mechanism has self-locking and can realize reverse self-locking, that is, the worm can only drive the worm wheel, but not the worm wheel. Such as the self-locking worm mechanism used in its heavy machinery, its reverse self-locking can play a safety protection role.

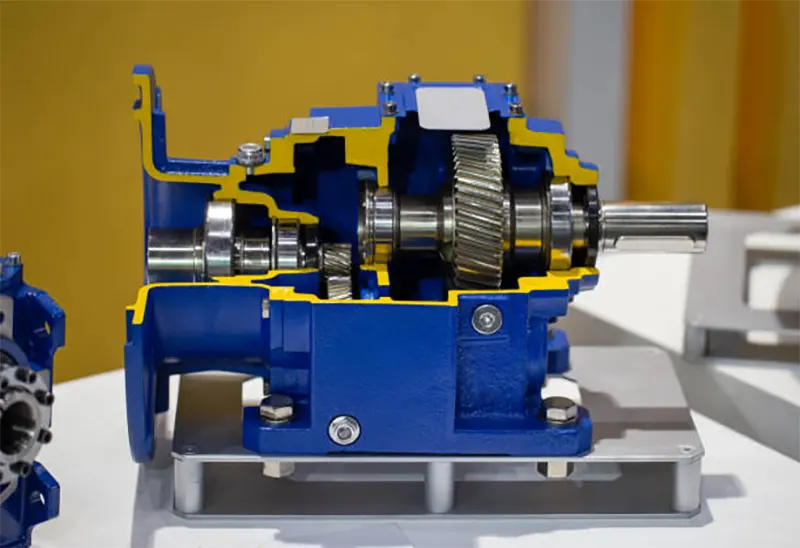

How Does a Worm Drive Gearbox Work?

As an efficient and compact transmission device, the Worm Gearbox not only achieves a high reduction ratio but also has self-locking characteristics, providing an important guarantee for the safe operation of the equipment.

Overview of Working Principle

The core of the worm gear reducer lies in the meshing transmission between the worm and the worm wheel. A worm is an shaft with helical teeth, while a worm gear is a cylindrical gear that meshes with it. When the worm rotates, its helical teeth will drive the worm wheel to rotate, thereby achieving the transmission of power and deceleration. This transmission mode not only has a compact structure but also can achieve significant deceleration within a limited space, making it highly suitable for applications that require precise control of speed and torque.

Analysis of Self-locking Characteristics

One of the most remarkable features of worm gearboxes is their self-locking capability. Self-locking refers to the ability of the output shaft to resist external forces without relative sliding under the action of a load. This characteristic stems from the unique geometric shape and mechanical properties of worm gear and worm transmission. Specifically, when the lead angle of the worm is less than the equivalent friction angle between the teeth of the meshing gear, the mechanism has self-locking properties. This means that under the action of a load, the worm gear cannot drive the worm in the opposite direction, thus achieving reverse self-locking.

Self-locking characteristics are extremely useful in mechanical applications, especially in situations where reverse rotation needs to be prevented or safety ensured. For instance, in fields such as lifting machinery, winches, and conveying equipment, the self-locking feature of worm drive gearboxes can ensure that when the equipment is powered off or loses power, the load will not accidentally slide down due to gravity, thereby safeguarding the safety of operators and the normal operation of the equipment.

However, it is worth noting that not all worm gearboxes have an ideal self-locking function. The realization of self-locking capability requires meeting certain conditions, such as the lead angle of the worm, the material of the worm wheel and worm, the manufacturing process, lubrication conditions, etc. In addition, the self-locking property may fail under extreme conditions, such as dry oil, insufficient lubrication or overheating. Therefore, in practical applications, these factors need to be comprehensively considered to ensure the stability and reliability of the self-locking function.

Transmission Efficiency Analysis

Although worm gearboxes have the significant advantage of self-locking, their relatively low transmission efficiency is also a drawback that cannot be ignored. This is mainly due to the fact that there is a large amount of sliding friction in the worm gear and worm transmission process, resulting in significant energy loss. Generally speaking, the transmission efficiency of worm gear reducers ranges from 70% to 95%, and the specific value depends on factors such as the design structure, material, manufacturing process, and lubrication conditions of the reducer.

To improve the transmission efficiency, a series of measures can be taken. For instance, high-quality metal materials are selected to manufacture worm gears and worms, and the processing technology and mating surface accuracy are optimized to reduce sliding friction and energy loss. Meanwhile, good lubrication is also the key to improving transmission efficiency. By regularly injecting lubricating oil, the friction and wear between the worm gear and worm can be reduced, thereby extending the service life of the reducer and improving the transmission efficiency.

In addition, the reduction ratio and input/output speed will also have an impact on the transmission efficiency. Generally speaking, when the reduction ratio is larger and the output speed is lower, the transmission efficiency is relatively higher. This is because as the reduction ratio increases, the slip friction loss is relatively small, thereby improving the transmission efficiency.

Installation of Worm Gear Reducers

Worm gear reducer assembly process is a very critical work, the following worm gear reducer assembly process and its steps.

- Prepare

Before the assembly of the worm reducer, it is necessary to make preparations. Preparations include cleaning the work area and preparing necessary tools and spare parts.

- Assemble worm gear and worm

When assembling the worm gear and worm, first fasten the bearing to the side of the worm gear. Then put the worm into the center hole of the worm wheel, and fix the assembled bearing in the lower hole slot of the worm wheel.

- Install the shaft

After the worm gear has been assembled, you can begin to install the shaft. When installing the shaft, it is necessary to install bearings at both ends of the shaft, and then load the shaft into the worm gear and worm.

- Install the cover plate and sealing ring

When installing the cover plate to the worm gearbox, be careful to keep it flat and properly connected. After installing the cover plate, you can install the seal ring. The installation of the sealing ring should be determined according to the actual situation.

- Check the worm gear reducer

After the worm drive gearbox is assembled, it is necessary to carefully check it again to ensure that it is installed correctly, functions normally, and is not loose.

- Lubricate

After completing the assembly of the worm reduction gearbox, it is also lubricated. In the lubrication process, the correct lubricating oil should be injected into the reducer to ensure that the reducer has a good lubrication effect.

Worm Reducer Gearbox Selection Guide

- Input power and torque

Input power and torque are determined according to the rated power and speed of the driving equipment (such as motors, engines, etc.)

- Output speed and torque

According to the actual operating speed and required torque of the working equipment, the output of the gear box is accurately determined by speed and torque. For example, a production equipment requires the output of 400N · m torque at a speed of 60r/min, then it is necessary to achieve a reasonable match between the input speed and the output speed through the gearbox transmission ratio, so as to meet the requirements of the output torque.

- Speed range

- Working Conditions on Selection

Working temperature and humidity

Dust and pollution

Vibration and shock

GBC Worm Reducers Testimonials

The worm gearbox for harvesters was a game-changer this season. Its dust-proof design cut field maintenance, and strong torque boosted cutting efficiency by 20%.”

“Our worm gearbox for concrete mixers exceeds expectations in wear resistance. It runs smoothly 8 hours daily under heavy loads, cutting maintenance by 50%.”

“Our conveyor belts use your worm gearbox for conveyor systems, and it’s been flawless for over a year. Stable torque, 30% less noise than our old model, and easy installation saved us maintenance time.”

Customization Options

We understand the uniqueness of each application and therefore provide flexible customization services. Our worm gearboxes, which are sold across New South Wales, Victoria, Queensland, and in major cities like Sydney, Melbourne, Brisbane, Adelaide, and Perth, can be tailored to your exact needs. Whether it’s a specific transmission ratio, mounting method, or special materials and motor adaptations you require, we’ve got you covered. We can customize worm gearboxes in Australia to ensure optimal performance and a perfect fit for your application.

Contact us, tell us your specific requirements, and let us provide you with a dedicated solution!

Ready to Find Your Worm Gearbox?

Contact us today for expert advice or to request a custom solution tailored to your needs.