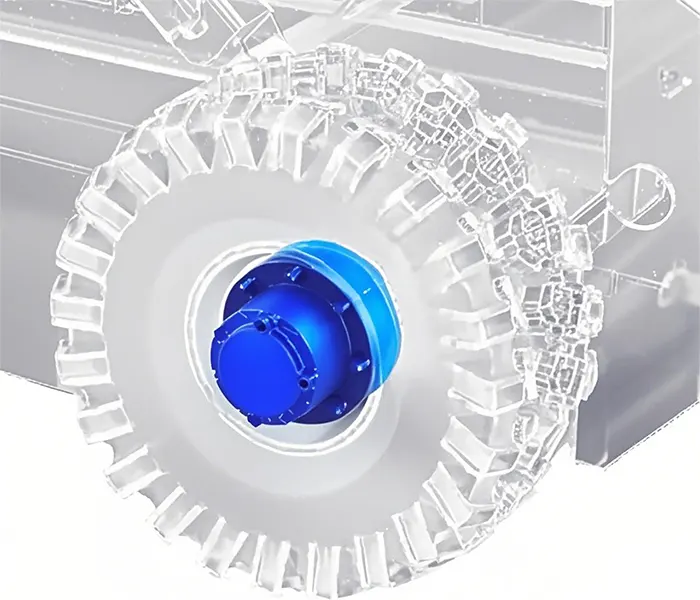

Wheel Drive Planetary Gearbox for Scissor Lift

The Wheel Drive Planetary Gearbox for Scissor Lift is an essential component designed to enhance the lifting mechanism’s efficiency and stability. It enables smooth torque transfer and precise control of lift movements, allowing for safe and effective operation in various lifting applications, such as construction and maintenance tasks.

Wheel Drive Planetary Gearbox for Scissor Lift

The Wheel Drive Planetary Gearbox for Scissor Lift is designed to provide high torque and efficiency, making it ideal for heavy lifting applications. Its compact design and robust construction ensure durability and reliability in demanding operational environments.

Specifications

- Gear Ratio: Customizable options available

- Input Power: Varies based on application

- Max Output Torque: Up to 500 Nm

- Efficiency: ≥ 95%

- Mounting Type: Vertical and horizontal configurations

- Weight: Lightweight design for easy installation

- Material: High-strength steel for longevity

| Specification | Details |

|---|---|

| Output torque range | 1000-60000 N.m |

| Gear ratios | i=5.3-142 |

| Support | The gearbox has rotating housing flanges to fit wheel |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulically released parking brake |

| Others | EP600L Series wheel drives with manual disconnect application |

| Load capacity | Large radial and axial load capacity due to the use of strong tapered roller bearings |

| Oil seal protection | Reliable oil seal protection, designed according to our field experience |

| Mounting flanges | Universal and SAE input direct mounting flanges |

| Direct mounting | The units are designed for their direct mounting into the wheel rims |

| Interchangeability | Technical data and installation dimension of EP600L Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 600 Series, so these three can be used interchangeably |

| Track drives Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP601 L1A | 1750 | 5.77 | 1000 | 450-600 |

| EP603 L2A | 4000 | 19-23-32-40 | 3000 | 210 |

| EP603 L2B | 4000 | 19-23-32-40 | 3000 | 210 |

| EP602 L2 | 5000 | 12.4-25.8 | 3000 | - |

| EP605 L2 | 7000 | 22-27-30-42-53 | 3000 | 220-310 |

| EP606 L2, L3 | 12000 | 30-35-43-68-79 | 3000 | 300-800 |

| EP607 L2, L3 | 17000 | 33-75-108 | 3000 | 300-600 |

| EP609 L2, L3 | 23000 | 33-142 | 3000 | 300-600 |

| EP610 L2, L3 | 30000 | 20-111 | 3000 | 300-800 |

| EP611 L2, L3 | 36000 | 41-47 | 3000 | 300-800 |

| EP613 L3 | 45000 | 108 | 3000 | 300-800 |

| EP615 L3 | 60000 | 108 | 3000 | 300-1000 |

Features and Advantages of Wheel Drive Planetary Gearbox for Scissor Lift

High Reduction Ratio: Achieves low-speed, high-torque output, making it suitable for heavy load applications.

Compact Integrated Design: Saves space by allowing direct installation in the wheel hub, reducing the complexity of the drive chain.

Load Distribution: Multi-planet gear design distributes stress, enhancing durability.

Efficient Transmission: Minimizes energy loss, improving overall system efficiency.

Modularity and Customization: Gear ratios and sizes can be adjusted based on load and speed requirements.

Advantages:

Reliability: Suitable for harsh environments, such as outdoor machinery.

Easy Maintenance: Compact structure allows for easy disassembly.

Low Noise and Stability: Multi-tooth engagement reduces vibration.

Selection Considerations for Wheel Drive Planetary Gearbox for Scissor Lift

When selecting a Wheel Drive Planetary Gearbox for a scissor lift, it is crucial to consider several factors. First, identify the load type: whether it is static or dynamic, as this influences the gearbox's performance and durability. Next, assess the working environment, including temperature, humidity, and dust levels, to ensure the gearbox can withstand these conditions. Lastly, determine the installation method, such as flange connection or shaft output, to guarantee compatibility and ease of installation. These factors will help ensure optimal functionality and longevity of the gearbox.

Why Choose Our Wheel Drive Planetary Gearbox for Scissor Lift

Choosing our Wheel Drive Planetary Gearbox ensures you receive a tailored solution designed to meet your specific needs, including customized gear ratios and installation methods. Our high-quality manufacturing process involves precision machining, guaranteeing low tolerances and extended lifespan. We offer comprehensive technical support, including selection guidance and after-sales service, to simplify your experience. Our gearbox reduces the complexity of the drive system while enhancing the overall performance and reliability of your equipment, making it the ideal choice for your scissor lift applications.

Maintenance Tips for Wheel Drive Planetary Gearbox in Scissor Lifts

To ensure optimal performance of your Wheel Drive Planetary Gearbox, follow these maintenance tips:

- Regularly check and top up lubricant levels to prevent overheating and wear.

- Inspect for leaks around seals and gaskets, addressing any issues promptly.

- Tighten bolts and fasteners periodically to maintain structural integrity.

- Clean the gearbox exterior to avoid dust accumulation that can cause overheating.

- Schedule professional inspections annually to catch potential problems early.

Wheel Drive Planetary Gearbox Supplier

GBC is the Australian sales agent for Ever-power Group, specializing in high-quality mechanical components and solutions. Our product range includes the advanced Wheel Drive Planetary Gearbox specifically designed for scissor lifts. These gearboxes are engineered for optimal performance, enhancing the efficiency and reliability of scissor lifts in various applications.

At GBC, we pride ourselves on providing exceptional products and services that cater to the specific needs of our clients. Our team is dedicated to offering customizable solutions to meet your unique requirements. We encourage customers to reach out for tailored designs and to explore our offerings.

Additional information

| Edited by | Sylvia |

|---|

The Wheel Drive Planetary Gearbox for Scissor Lift is an essential component designed to enhance the lifting mechanism’s efficiency and stability. It enables smooth torque transfer and precise control of lift movements, allowing for safe and effective operation in various lifting applications, such as construction and maintenance tasks.