Machinable Bore Sprocket for ANSI 200 Roller Chain (2 1/2″ Pitch)

The Machinable Bore Sprocket for ANSI 200 Roller Chain is designed for optimal performance and durability in various industrial applications. With a 2 1/2″ pitch, it ensures seamless integration and enhanced efficiency in your machinery. Trust GBC for high-quality sprockets available in Australia, delivering reliability and precision you can count on.

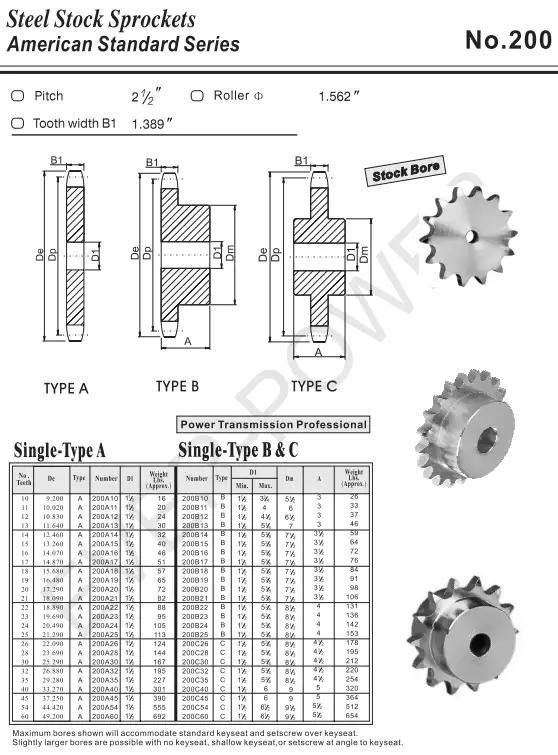

Specifications for Machinable Bore Sprocket for ANSI 200 Roller Chain (2 1/2" Pitch)

A machinable bore sprocket is an essential component commonly used across various industries to efficiently transmit rotary motion between two shafts via a roller chain. The Machinable Bore Sprocket designed for ANSI 200 Roller Chain (2 1/2" Pitch) features specific characteristics that make it suitable for high-performance applications. This type of sprocket allows customization of the bore size to fit different shaft diameters, ensuring compatibility and optimal functionality in various machinery setups.

Basic Structure and Customization

The structure of a machinable bore sprocket consists of a circular disc equipped with teeth that engage with the roller chain's links. Customizing a machinable bore sprocket requires consideration of several key factors:

- Material: Machinable bore sprockets can be manufactured from high carbon steel, alloy steel, or stainless steel. Each material brings unique benefits that cater to specific environmental conditions and mechanical requirements.

- Tooth Profile: The tooth profile is crucial for effective chain engagement. Sprockets can feature various profiles, including involute, standard tooth, and hunting tooth, each offering distinct advantages depending on application needs.

- Number of Teeth: The quantity of teeth on the sprocket plays a vital role in determining the speed ratio between the driving and driven shafts, directly impacting operational efficiency.

- Dimensions: Specific dimensions, such as the outer diameter and thickness, must be tailored to meet the application's needs, ensuring proper fit and function.

- Bore Size: The bore size is the diameter of the central hole in the sprocket, which must align perfectly with the shaft's diameter for secure installation.

- Keyway: The keyway is a vital slot on the bore, allowing for a secure connection between the sprocket and the shaft using a key, preventing slippage during operation.

- Surface Treatment: Surface treatments enhance durability and corrosion resistance, with options including anti-rust coatings and hardening processes to extend the sprocket's lifespan.

Material and Manufacturing Process

Machinable bore sprockets are produced from high carbon steel, alloy steel, or stainless steel, chosen based on application requirements. The manufacturing process includes several critical steps:

- Material Selection: The selection process considers factors like strength, wear resistance, and corrosion resistance to ensure optimal performance.

- Cutting and Stamping: The chosen material undergoes cutting and stamping to form the desired shape of the sprocket.

- Machining: Machining processes, including turning, milling, drilling, and tapping, are employed to achieve precise dimensions and tooth profiles necessary for optimal functionality.

- Heat Treatment: Heat treatment processes like quenching, tempering, and surface hardening are utilized to enhance the sprocket's hardness and overall strength.

- Surface Treatment: The surface is treated with anti-rust coatings to prevent corrosion and prolong the sprocket's life.

- Quality Inspection: Every sprocket is subjected to stringent quality inspections, ensuring dimensional accuracy and mechanical integrity.

Applications

The Machinable Bore Sprocket for ANSI 200 Roller Chain has a wide range of applications across numerous industries, including:

- Heavy Machinery and Equipment: These sprockets are integral in heavy machinery, facilitating reliable power and motion transfer.

- Food Processing and Packaging: In the food industry, sprockets play a critical role in conveyor systems and packaging machinery, ensuring smooth operations.

- Chemical and Pharmaceutical: They are used in various chemical processing and pharmaceutical manufacturing equipment, crucial for operational efficiency.

- Assembly Lines: Sprockets are vital components in assembly lines, ensuring consistent movement and product flow.

- Logistics and Warehousing: Sprockets are utilized in conveyor systems designed for efficient material handling and storage solutions.

Maintenance and Troubleshooting

To ensure optimal performance and longevity of machinable bore sprockets, proper maintenance is essential. Regular maintenance practices include:

- Daily Inspection: Conduct frequent inspections to identify signs of damage, wear, or misalignment early on.

- Cleaning: Keep the sprocket clean, preventing dirt, debris, and lubricant accumulation that can hinder performance.

- Lubrication: Regularly apply suitable lubrication to minimize friction and reduce premature wear on the sprocket.

- Adjustment and Calibration: Regularly check the roller chain's tension and alignment, making necessary adjustments to maintain efficiency.

Common issues with sprockets may include tooth skipping, breakage, wear, excessive noise, and chain disengagement. Solutions to these problems involve:

- Tooth Skipping: Assess for misalignment or wear in the chain and sprocket, replacing any damaged parts as needed.

- Breakage: Inspect for cracks or fatigue; replace the sprocket if structural integrity is compromised.

- Wear: Monitor tooth wear regularly and replace the sprocket when it exceeds acceptable wear limits.

- Excessive Noise: Check chain tension and alignment, adjusting or replacing components to eliminate noise.

- Chain Disengagement: Ensure proper chain tension and secure all connections to prevent disengagement during operation.

Machinable Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are one of the best sprocket suppliers in Australia. Our specialty lies in providing high-quality machined bore sprockets designed specifically for ANSI 200 roller chains (2 1/2" pitch). We pride ourselves on our exceptional quality, ensuring that every sprocket meets stringent standards for durability and performance.

At GBC, we offer comprehensive pre-sales and post-sales services to assist our customers every step of the way. Our knowledgeable team is dedicated to helping you find the right sprocket solutions for your needs, and we are always available to provide support after your purchase.

Additionally, we understand that every customer has unique requirements. Therefore, we offer non-standard customization options to tailor our products according to your specific needs and preferences.

Additional information

| Edited by | Sylvia |

|---|

The Machinable Bore Sprocket for ANSI 200 Roller Chain is designed for optimal performance and durability in various industrial applications. With a 2 1/2″ pitch, it ensures seamless integration and enhanced efficiency in your machinery. Trust GBC for high-quality sprockets available in Australia, delivering reliability and precision you can count on.