Metric Bore Sprocket for ISO ASA25 Roller Chain (6.35mm Pitch)

The Metric Bore Sprocket for ISO 606 and DIN 8187 ASA25 Roller Chain (6.35mm Pitch) is designed for durability and precision in various mechanical applications. Its robust construction ensures reliable performance, making it ideal for power transmission systems. GBC proudly offers high-quality Metric Bore Sprockets in Australia.

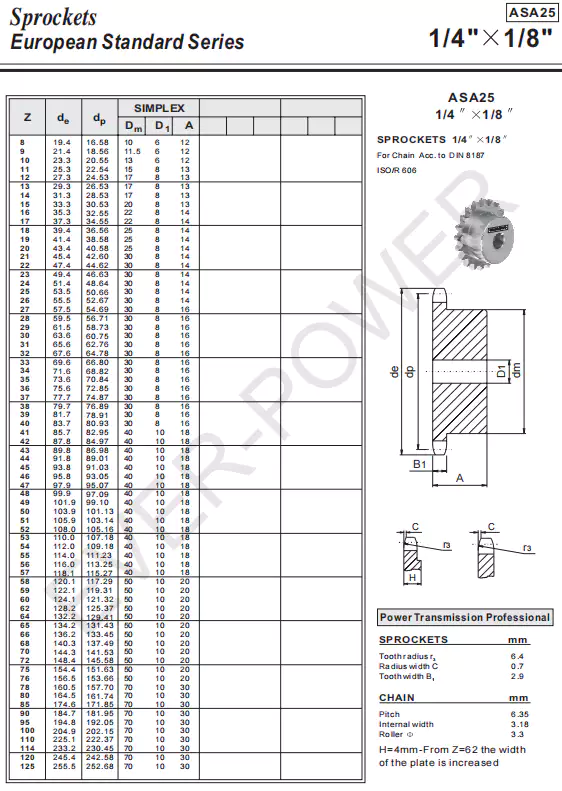

Specifications: Metric Bore Sprocket for ISO ASA25 Roller Chain (6.35mm Pitch)

A metric bore sprocket is a specialized type of sprocket designed to accommodate various shaft sizes while adhering to standardized bore diameters. The Metric Bore Sprocket for ISO ASA25 Roller Chain, specifically, is an essential component utilized across multiple industries due to its versatility and reliability. This sprocket comes with a pitch of 6.35 mm, a roller width of 3.18 mm, and features a standard hub diameter that can range from 12.7 mm to 63.5 mm, making it suitable for a wide range of applications.

Basic Structure and Customization of Sprockets

The structure of a sprocket is fundamentally composed of two critical parts: the toothed wheel and the hub. The toothed wheel has evenly distributed teeth that effectively engage with a chain, allowing for the efficient transmission of power. The hub is the central part that attaches to the shaft, providing stability and support during operation.

Customization options for sprockets are extensive and include selecting the appropriate material, tooth profile, number of teeth, pitch, hub bore size, keyway, and surface treatment. These specifications are vital for ensuring optimal performance, durability, and longevity of the sprocket in its intended application.

- Material: The Metric Bore Sprocket for ISO ASA25 Roller Chain is commonly manufactured from high carbon steel, alloy steel, or stainless steel, depending on the specific demands of the application.

- Tooth Profile: Various tooth profiles are available, such as the traditional ANSI tooth profile or custom-designed configurations tailored to specific needs.

- Number of Teeth: The number of teeth on the sprocket is chosen based on the application's requirements and the desired ratio with another driving sprocket.

- Pitch: The pitch is defined as the distance between two adjacent chain pins. For the Metric Bore Sprocket, the pitch is set at 6.35 mm.

- Hub Bore Size: The hub bore size is essential as it determines the diameter of the shaft that the sprocket is designed to fit on, ensuring a secure connection.

- Keyway: Incorporating a keyway into the hub allows for a key to be inserted, which secures the sprocket onto the shaft, preventing slippage.

- Surface Treatment: Surface treatments such as galvanization or coating can be applied to enhance rust and corrosion resistance, thus increasing the lifespan of the sprocket.

Materials and Manufacturing Process

The manufacturing of the Metric Bore Sprocket for ISO ASA25 Roller Chain is conducted using high-quality materials and a stringent process that ensures durability and functionality. The process encompasses several key stages:

- Material Selection: High carbon steel, alloy steel, or stainless steel are chosen based on the application's specific requirements to ensure optimal performance.

- Cutting: Advanced cutting tools are employed to achieve precise dimensions, which is critical for proper fitting and operation.

- Forming: The sprocket is then shaped using mechanical or forging presses to obtain the desired form.

- Machining: Subsequent machining processes, including turning, milling, drilling, and tapping, refine the sprocket's specifications further.

- Heat Treatment: Heat treatment methods such as quenching and tempering are applied to enhance the strength and hardness of the sprocket based on the selected materials.

- Surface Treatment: Various surface treatments are applied to prevent rust and corrosion, employing methods like electroplating, painting, or powder coating.

- Quality Control: Rigorous quality control checks are integrated throughout the manufacturing process to verify that each sprocket meets established standards and specifications.

Applications

The Metric Bore Sprocket for ISO ASA25 Roller Chain enjoys widespread application across various industries, including:

- Heavy Machinery and Equipment: This sprocket is vital for heavy machinery such as bulldozers and excavators, where reliable power transmission is crucial.

- Food Processing and Packaging: Its corrosion-resistant properties make it ideal for applications in the food industry, where hygiene and cleanliness are paramount.

- Chemical and Pharmaceutical: The sprocket's resistance to harsh chemicals and high temperatures makes it suitable for the chemical and pharmaceutical manufacturing sectors.

- Assembly Lines: It is widely used in assembly lines for transporting products, contributing to efficient production processes.

- Logistics and Warehousing: Commonly found in conveyor systems, this sprocket facilitates the movement of goods within warehouses and logistics operations.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of a sprocket, regular maintenance and troubleshooting are critical. The following steps should be actively practiced:

- Daily Inspection: Conduct daily checks for signs of wear, damage, or misalignment to catch potential issues early.

- Cleaning: Regular cleaning of the sprocket is essential to remove debris or dirt that could lead to various forms of damage.

- Lubrication: Applying lubricant periodically helps reduce friction and wear, extending the sprocket's operational life.

- Adjustment and Calibration: Continual adjustment and calibration ensure that the sprocket remains properly aligned and functions efficiently.

- Troubleshooting: Address common issues such as skipped teeth, breakage, and noise by identifying and rectifying the root causes promptly.

Other Types of Sprockets

Beyond the Metric Bore Sprocket for ISO ASA25 Roller Chain, there are several other types of sprockets available that cater to varying applications, including:

- Platewheel Sprocket: This sprocket type features a plate or disc design in lieu of a traditional hub.

- Idler Sprocket: Serves to guide the chain while also maintaining necessary tension.

- QD Sprocket: This design incorporates a quick-disconnect mechanism for ease of installation and removal.

- Taper Lock Sprocket: Utilizes a taper bushing, allowing for straightforward installation and removal.

A comprehensive range of compatible chains is also available, providing a complete power transmission solution to enhance operational efficiency.

Metric Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the best sprocket suppliers in Australia. Our range includes the Metric Bore Sprocket for ISO ASA25 Roller Chain (6.35mm Pitch), designed with precision engineering to ensure optimal performance in various applications. We prioritize quality, utilizing high-grade materials and advanced manufacturing processes that meet international standards.

At GBC, we understand the importance of excellent customer service. Our dedicated pre-sales team is ready to assist clients in selecting the right sprocket for their needs, while our after-sales support ensures any issues are resolved swiftly and efficiently. Additionally, we offer non-standard customization based on customer requirements, allowing us to provide tailored solutions that fit specific operational demands.

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket for ISO 606 and DIN 8187 ASA25 Roller Chain (6.35mm Pitch) is designed for durability and precision in various mechanical applications. Its robust construction ensures reliable performance, making it ideal for power transmission systems. GBC proudly offers high-quality Metric Bore Sprockets in Australia.