Metric Bore Sprocket for ISO 05B Roller Chain (8mm Pitch)

The Metric Bore Sprocket for ISO 606 and DIN 8187 05B Roller Chain (8mm Pitch) is designed for optimal performance and durability in various applications. Engineered with precision, it ensures smooth operation and longevity, making it an essential component for your machinery. GBC proudly offers high-quality Metric Bore Sprockets in Australia.

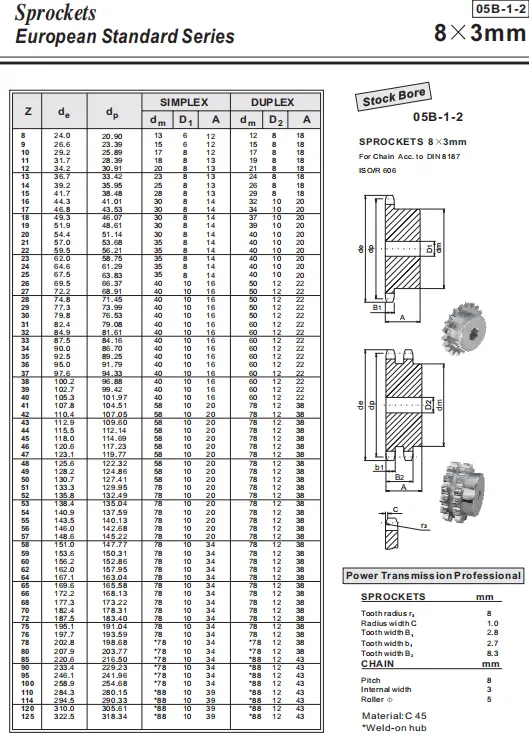

Specifications for Metric Bore Sprocket for ISO 05B Roller Chain (8mm Pitch)

The Metric Bore Sprocket for ISO 05B Roller Chain (8mm Pitch) is a specialized component crucial for the effective functioning of roller chain systems in various industrial applications. This sprocket is engineered to fit precisely with the ISO 05B roller chain, ensuring compatibility and optimal performance. With a standard bore size, it provides ease of installation and adaptability for different setups where space and efficiency are key considerations.

Basic Structure and Customization

A metric bore sprocket features a circular disc outfitted with teeth designed to engage with the ISO 05B roller chain securely. When customizing such a sprocket, several critical factors must be taken into account:

- Material: The material choices for this sprocket include high carbon steel, alloy steel, and stainless steel, each providing its unique advantages based on application demands and environmental conditions.

- Tooth Profile: The tooth profile of the sprocket is integral to how effectively it meshes with the chain. Different profiles are tailored to specific applications, enhancing performance and reducing wear over time.

- Number of Teeth: The sprocket's tooth count significantly influences its gear ratio, which in turn dictates the speed relationship between the driving and driven machinery.

- Dimensions: Key dimensions, including outer diameter and width, are essential to guarantee proper fit and alignment with other mechanical components, ensuring smooth operation.

- Bore Size: The bore size determines the diameter of the central hole through which the sprocket is mounted onto a shaft, affecting its stability and function.

- Keyway: A keyway is a slot integrated into the bore for secure attachment to the shaft using a key, enhancing the sprocket's connection and preventing slippage.

- Surface Treatment: Application of surface treatments, such as rust protection, is vital to extend the sprocket's lifespan and maintain effective operation, especially in harsh environments.

Materials and Manufacturing Processes

Our metric bore sprockets are produced from high-quality materials, ensuring durability and precision through rigorous manufacturing processes. These include material selection, cutting, punching, forging, and machining methods such as turning, milling, and drilling. Heat treatment processes, including quenching and tempering, enhance the material strength, while surface hardening and treatment provide additional protection against wear and corrosion. Finally, thorough quality testing is conducted to guarantee that each sprocket meets high standards of performance and reliability.

Applications of Metric Bore Sprocket for ISO 05B Roller Chain

The Metric Bore Sprocket for ISO 05B Roller Chain (8mm Pitch) is widely utilized across various sectors, including:

- Heavy machinery and equipment

- Food processing and packaging applications

- Chemical and pharmaceutical industries

- Assembly lines and manufacturing

- Logistics and warehousing operations

Maintenance and Care

To ensure the longevity and optimal performance of the metric bore sprocket, proper maintenance and care are paramount:

- Daily Inspection: Regularly examine the sprocket for any signs of wear, damage, or misalignment that could hinder performance.

- Cleaning: It is essential to keep the sprocket free from dust, debris, and other contaminants that may compromise its function and efficiency.

- Lubrication: Proper lubrication is crucial to minimize friction and prevent premature wear on the sprocket and chain, enhancing their operational life.

- Adjustment and Calibration: Routine checks and adjustments should be made to ensure the sprocket's alignment and calibration remain within optimal performance parameters.

Common issues that may arise with sprockets include tooth skipping, breakage, wear, excessive noise, and chain derailment. To troubleshoot these problems:

- Tooth Skipping: Inspect for worn-out teeth or inadequate lubrication. Replace the sprocket or add lubrication as necessary to restore function.

- Breakage: Look for cracks or physical damage on the sprocket. If any defects are found, replacement is essential to maintain safety and performance.

- Wear: Conduct regular inspections for signs of wear on the teeth. Prompt replacement is necessary to prevent further damage and ensure reliability.

- Excessive Noise: Assess for misalignment, insufficient lubrication, or damaged teeth. Address the root cause to eliminate noise issues effectively.

- Chain Derailment: Ensure that the chain tension is correctly adjusted and that sprocket teeth are intact and undamaged to prevent derailment.

Plain Bore Sprockets Supplier - GBC

GBC is the sales agent for Ever-power Group in Australia, and we are proud to be one of the best sprocket suppliers in the region. Our Metric Bore Sprockets for ISO 05B Roller Chain (8mm Pitch) are designed to meet the highest standards of quality and performance. We utilize advanced manufacturing processes to ensure that our sprockets are durable, reliable, and suitable for various applications.

In addition to our commitment to quality, GBC offers exceptional pre-sales and after-sales services. Our knowledgeable staff is always ready to assist customers in selecting the right sprockets for their needs, and we provide support even after the purchase to ensure complete satisfaction.

Furthermore, we understand that every customer has unique requirements, which is why we offer non-standard customization options to tailor our products to specific needs. Trust GBC for all your sprocket needs!

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket for ISO 606 and DIN 8187 05B Roller Chain (8mm Pitch) is designed for optimal performance and durability in various applications. Engineered with precision, it ensures smooth operation and longevity, making it an essential component for your machinery. GBC proudly offers high-quality Metric Bore Sprockets in Australia.