Plain Bore Sprocket NK140B/NK140C (44.45mm Pitch)

The Plain Bore Sprocket NK140B/NK140C features a pitch of 44.45mm, designed for durability and precision in various applications. Its robust construction ensures optimal performance and reliability. GBC proudly offers high-quality Plain Bore Sprockets in Australia, catering to the needs of our valued customers.

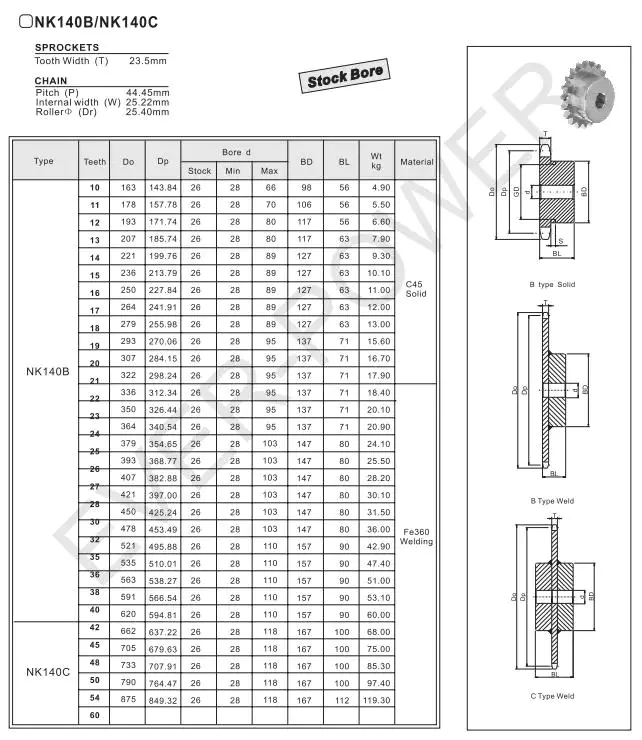

Specifications: Plain Bore Sprocket NK140B/NK140C (44.45mm Pitch)

A plain bore sprocket is a vital element in various mechanical systems, specifically designed to facilitate the transfer of rotational motion between multiple shafts through a chain. The Plain Bore Sprocket NK140B/NK140C, highlighted in the selection chart below, is a premium quality sprocket that adheres to industry standards, ensuring reliable performance across applications.

Basic Structure of a Sprocket

A sprocket is composed of several key components that are crucial when considering customization options. These include:

- Material: Sprockets can be manufactured from high carbon steel, alloy steel, or stainless steel, depending on the specific requirements of the application and the environment in which they will operate.

- Tooth Profile: The design of the sprocket's teeth is critical, as it dictates how the chain engages with the sprocket, influencing the overall efficiency and functionality of the system.

- Number of Teeth: The quantity of teeth on the sprocket determines the speed ratio as well as the torque transmission, impacting the performance characteristics of the connected machinery.

- Dimensions: The dimensions, including outer diameter and thickness, must be precisely specified in accordance with the needs of the system to ensure compatibility and proper fit.

- Bore: The central hole of the sprocket must be accurately sized to fit the shaft for which it is intended, allowing for a secure and effective mount.

- Keyway: A keyway may be included, if required, to promote a stable connection between the shaft and the sprocket, preventing slippage during operation.

- Surface Treatment: Various surface treatments are available, such as rust prevention techniques, to enhance the durability and longevity of the sprocket, ensuring optimal performance over time.

Material and Manufacturing Process

Our sprockets are crafted from high-quality materials, undergoing meticulous manufacturing processes to guarantee their durability and lasting performance. The materials utilized are chosen based on the specific application needs, including options like high carbon steel, alloy steel, or stainless steel. The manufacturing steps encompass:

- Material Selection: The choice of material is made to align with the demands of the application, ensuring that the sprocket can withstand operational stresses.

- Cutting and Stamping: The selected material is shaped through cutting and stamping, creating the initial form of the sprocket.

- Machining: Various machining techniques—like turning, milling, and drilling—are employed to achieve the precise dimensions and tooth profile required for optimal function.

- Heat Treatment: The sprocket undergoes heat treatment processes, such as quenching and tempering, to enhance its hardness and strength, providing resilience under load.

- Surface Treatment: To combat rust and corrosion, surface treatments are applied, which help maintain the sprocket's performance over extended periods.

- Quality Inspection: Each sprocket is subjected to thorough quality inspections to ensure that it meets both industry standards and specific customer requirements.

Applications

The NK140B/NK140C Plain Bore Sprocket is utilized across various industries, including:

- Heavy Machinery and Equipment: This sprocket is often incorporated into heavy-duty machinery, playing a pivotal role in power transmission applications.

- Food Processing and Packaging: In the food industry, the sprocket is essential for conveying and packaging processes, ensuring efficiency and reliability.

- Chemical and Pharmaceutical: Applications in chemical and pharmaceutical sectors leverage the sprocket for precise material handling, contributing to operational accuracy.

- Assembly Lines: Integral to assembly lines, this sprocket facilitates seamless and synchronized operations, boosting productivity.

- Logistics and Warehousing: Sprockets are widely used in conveyor systems, assisting with transportation and storage solutions in logistics operations.

Maintenance and Troubleshooting

To ensure optimal performance and extend the lifespan of the sprocket, regular maintenance and inspections are crucial. Key maintenance practices include:

- Daily Checks: Regular inspections help identify wear, damage, or misalignment that could affect performance.

- Cleaning: Keeping the sprocket free from dirt and contaminants is essential for maintaining its efficiency and functionality.

- Lubrication: Appropriate lubrication is vital for reducing friction, which helps promote smooth operation and reduces wear.

- Adjustment and Calibration: Periodically checking and adjusting the tension and alignment of the chain and sprocket is necessary to maintain proper function.

Common issues associated with sprockets can include tooth skipping, breakage, wear, excessive noise, and chain detachment. The following solutions can help address these challenges:

- Tooth Skipping: Misalignment or excessive wear should be checked; realigning or replacing the sprocket may be necessary.

- Breakage: Inspect for signs of fatigue or overload; replacement may be warranted if damage is detected.

- Wear: Monitoring wear patterns regularly allows for replacement before critical limits are reached, ensuring continued performance.

- Excessive Noise: Proper lubrication and alignment checks can help mitigate excessive noise, improving overall operation.

- Chain Detachment: Verifying the tension and alignment of the chain, along with replacing worn components, can prevent detachment.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the best sprocket suppliers in Australia. Our commitment to quality is evident in our range of Plain Bore Sprockets, including the NK140B/NK140C with a 44.45mm pitch. These sprockets are designed for durability and high performance, ensuring they meet the rigorous demands of various applications.

At GBC, we prioritize customer satisfaction by offering exceptional pre-sales and after-sales services. Our knowledgeable team is ready to assist you in selecting the right sprocket for your needs and providing support even after your purchase. Additionally, we understand that every customer has unique requirements, so we offer non-standard customization options to meet specific demands.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK140B/NK140C features a pitch of 44.45mm, designed for durability and precision in various applications. Its robust construction ensures optimal performance and reliability. GBC proudly offers high-quality Plain Bore Sprockets in Australia, catering to the needs of our valued customers.