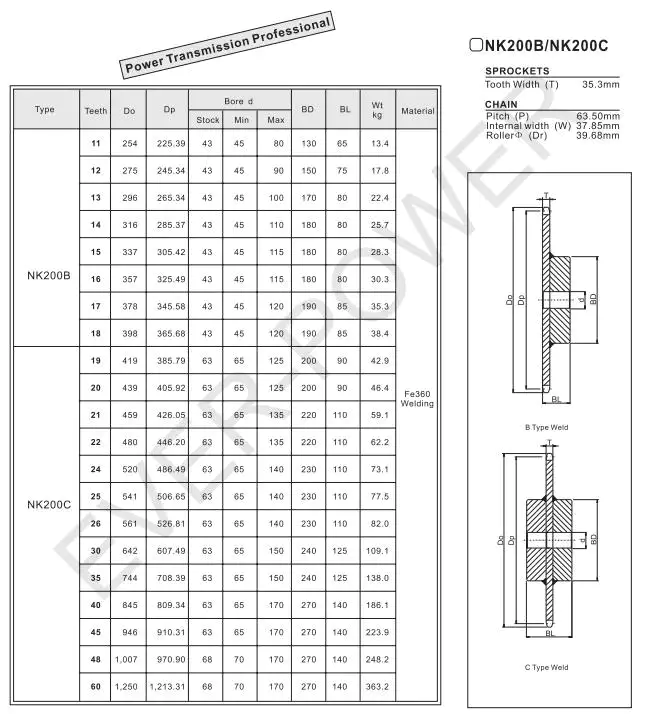

Plain Bore Sprocket NK200B/NK200C (63.5mm Pitch)

The Plain Bore Sprocket NK200B/NK200C features a 63.5mm pitch, designed for durability and efficiency in various applications. Its robust construction ensures reliable performance in demanding environments. GBC proudly offers high-quality Plain Bore Sprockets in Australia, ensuring you receive the best products for your needs.

Specifications Plain Bore Sprocket NK200B/NK200C (63.5mm Pitch)

A plain bore sprocket is a specialized type of sprocket utilized in various industrial applications. It is engineered to efficiently transmit rotational motion between two shafts through a chain mechanism. The plain bore sprocket serves as a crucial element in numerous machinery and equipment systems, facilitating smooth operation and enhancing overall machinery performance.

Basic Structure of Sprocket

A sprocket comprises several critical elements necessary for custom fabrication:

- Material: Sprockets can be made from high carbon steel, alloy steel, or stainless steel, chosen based on the specific demands of the application.

- Tooth Profile: The design of the tooth profile is fundamental as it influences the efficient transfer of power and the overall effectiveness of the sprocket.

- Number of Teeth: The number of teeth plays a significant role in determining the speed ratio and precise movement of the chain, impacting the machinery's functionality.

- Dimensions: Accurate dimensions, including outer diameter and width, are vital for ensuring proper integration within the machinery.

- Bore Size: The bore size refers to the diameter of the central hole, which allows for mounting the sprocket onto a shaft securely.

- Keyway: The keyway is a critical slot that aids in locating and centering the sprocket on the shaft, ensuring stability during operation.

- Surface Treatment: The sprocket's surface may undergo treatments to improve hardness, corrosion resistance, and enhance overall durability, thereby extending its life.

Materials and Manufacturing Process

Our plain bore sprockets are crafted from premium materials through advanced manufacturing techniques:

- Material: We select high carbon steel, alloy steel, or stainless steel tailored to meet specific application needs.

- Manufacturing Process: The production of our sprockets involves meticulous steps, including material selection, cutting, stamping, forging, machining, heat treatment, surface hardening, rust prevention, and rigorous quality inspection to ensure optimal performance and reliability.

Applications

The Plain Bore Sprocket NK200B/NK200C is employed across various industries, highlighting its versatility:

- Heavy Machinery and Equipment: Designed to endure high loads, these sprockets deliver dependable performance in heavy-duty machinery applications.

- Food Processing and Packaging: Sprockets used in food-related sectors comply with stringent hygiene and safety standards, making them suitable for sensitive environments.

- Chemical and Pharmaceutical: Our sprockets are engineered to resist corrosion, enabling them to thrive in harsh chemical contexts.

- Assembly Lines: Playing a vital role in conveyor systems, sprockets are essential for efficient assembly line operations.

- Logistics and Warehousing: Used in material handling equipment such as forklifts and conveyor belts, these sprockets enhance efficiency in warehouses and distribution centers.

Maintenance and Troubleshooting

To ensure longevity and optimal performance, proper maintenance and regular inspections are imperative:

- Daily Inspection: Conduct checks for any signs of damage, misalignment, or abnormal wear to maintain functionality.

- Cleaning: Regularly remove dirt, debris, and lubricant buildup to prevent interference with the chain's movement, which could hinder operations.

- Lubrication: Apply suitable lubrication consistently to reduce friction, which helps in preventing premature wear and tear of the sprocket.

- Adjustment and Calibration: Necessary adjustments should be made to ensure proper tension and alignment of the chain, thus enhancing operational efficiency.

Common Issues and Solutions:

- Skipping Teeth: This may arise from worn-out teeth or inadequate chain tension. Address this by replacing the sprocket or adjusting the chain tension appropriately.

- Breakage: Inspect the sprocket for cracks or fractures. If any are found, replace the sprocket to avoid further issues.

- Wear: Prolonged use or inadequate lubrication can lead to wear. Implementing regular maintenance and proper lubrication can significantly reduce wear.

- Noise: Excessive noise could indicate misalignment or worn sprocket teeth. Adjust alignment or replace the sprocket as necessary to resolve this issue.

- Chain Slippage: Inspect the chain for loose or damaged links. Repairing or replacing the chain will help prevent further slippage and ensure smooth operation.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the leading sprocket suppliers in Australia. Our commitment to quality and customer satisfaction sets us apart in the industry. We specialize in a variety of sprockets, including the Plain Bore Sprocket NK200B/NK200C, which features a 63.5mm pitch, designed for optimal performance in various applications.

At GBC, we prioritize quality in every product we offer. Our sprockets are manufactured using premium materials and state-of-the-art technology to ensure durability and reliability. We also provide comprehensive pre-sales and after-sales support, assisting our customers throughout their purchasing journey and ensuring satisfaction long after the sale.

Moreover, we understand that each customer has unique needs. Therefore, we offer non-standard customization options to meet specific requirements, ensuring that you receive the perfect solution for your application.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK200B/NK200C features a 63.5mm pitch, designed for durability and efficiency in various applications. Its robust construction ensures reliable performance in demanding environments. GBC proudly offers high-quality Plain Bore Sprockets in Australia, ensuring you receive the best products for your needs.