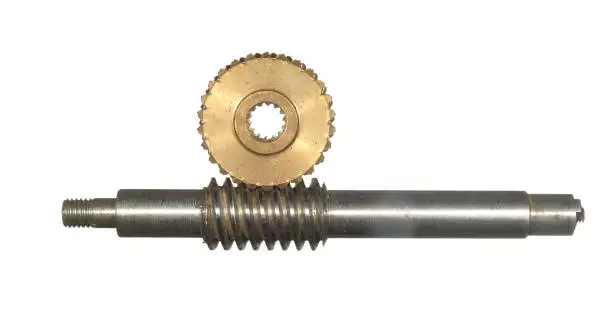

Brass Worm Wheel

The Brass Worm Wheel is a critical component in various mechanical systems, designed to work seamlessly with brass worm gears. Constructed from high-quality brass, this durable wheel provides excellent wear resistance and low friction properties. Its primary function is to transmit motion and torque efficiently between non-intersecting shafts, making it ideal for applications in machinery and automotive systems. The worm gear mechanism allows for smooth operation, enhancing the overall performance of devices utilizing the brass worm wheel.

Specifications of Brass Worm Wheel

| Specifications | |

|---|---|

| Material | Brass |

| Color | Yellow |

| Modulus | 0.5 |

| Weight | 16g |

| Size of the worm wheel | |

|---|---|

| Teeth | 20 |

| Teeth Dia | 11.2mm |

| Height | 12mm/0.47inch |

| Outer Diameter | 11mm/0.43inch |

| Hole Diameter | 4mm/0.16inch |

| Step Size | 9x7mm/0.35x0.27inch ( Dia x H) |

| Overall Size | 12x11x4mm/0.47x0.39x0.12inch( H x OD x ID) |

| Size of worm gear shaft | |

|---|---|

| Height | 20mm/0.79inch |

| Outer Diameter | 9.8mm/0.39inch |

| Inner Diameter | 3.17mm/0.12inch |

| Size | 20x9.8x3.17mm/0.79x0.39x0.12inch( H x OD x ID) |

Features and Advantages of Brass Worm Wheel

- High Durability: The Brass Worm Wheel is engineered from high-quality brass, ensuring long-lasting performance under various operating conditions.

- Excellent Load Distribution: This worm gear design allows for efficient load distribution, minimizing wear and extending the lifespan of the gear.

- Corrosion Resistance: Brass is naturally resistant to corrosion, making the Brass Worm Gear ideal for applications in humid or corrosive environments.

- Smooth Operation: The precise manufacturing process ensures smooth engagement between the worm gear and the brass worm wheel, resulting in quiet and efficient operation.

Applications of Brass Worm Wheel in Mechanical Systems

The Brass Worm Wheel is an essential component in various mechanical systems, providing efficient power transmission and torque multiplication. Widely used in industries such as robotics, conveyor systems, and automotive applications, the brass worm gear offers durability and resistance to wear. The unique design of the worm gear allows for smooth operation and reduced noise, making it ideal for high-performance machinery. By integrating a brass worm wheel, engineers can achieve precise control and increased efficiency in their projects. Discover the benefits of incorporating a brass worm gear in your next design.

Maintenance Tips for Brass Worm Wheel

- Regular Inspection for Wear and Tear:

To ensure the longevity of your brass worm wheel, it is crucial to conduct regular inspections. Examine the worm gear and the brass worm wheel for any signs of wear, such as scoring or uneven teeth. If you notice any irregularities, it may indicate that the components are under excessive stress or misaligned. Regular checks will help in identifying issues early, allowing for timely repairs or replacements. This proactive approach not only extends the life of the brass worm gear but also ensures optimal performance. Remember, addressing wear and tear promptly can save you from costly repairs in the future. - Proper Lubrication:

Lubrication is key to maintaining the efficiency of the brass worm wheel and worm gear. Using the correct type of lubricant reduces friction, which in turn minimizes heat generation and wear on the brass components. Make sure to apply lubricant to both the worm gear and the brass worm wheel regularly. This practice not only enhances the smooth operation of the gear system but also protects the brass from corrosion and premature wear. Selecting a high-quality lubricant specifically designed for brass materials will yield the best results, ensuring that your brass worm wheel operates seamlessly for years to come. - Avoid Overloading:

One of the main reasons for premature wear of the brass worm gear and worm wheel is overloading. Ensure that the load applied does not exceed the specified limits for the gear system. Overloading can cause excessive stress on the brass components, leading to deformation and eventual failure. To prolong the life of your brass worm wheel, always adhere to the manufacturer's specifications regarding load capacity. This careful management not only maintains the integrity of the components but also ensures safety during operation.

Worm Gear Manufacturer - GBC

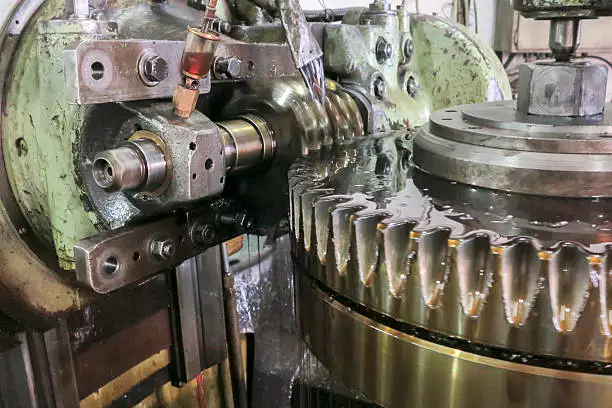

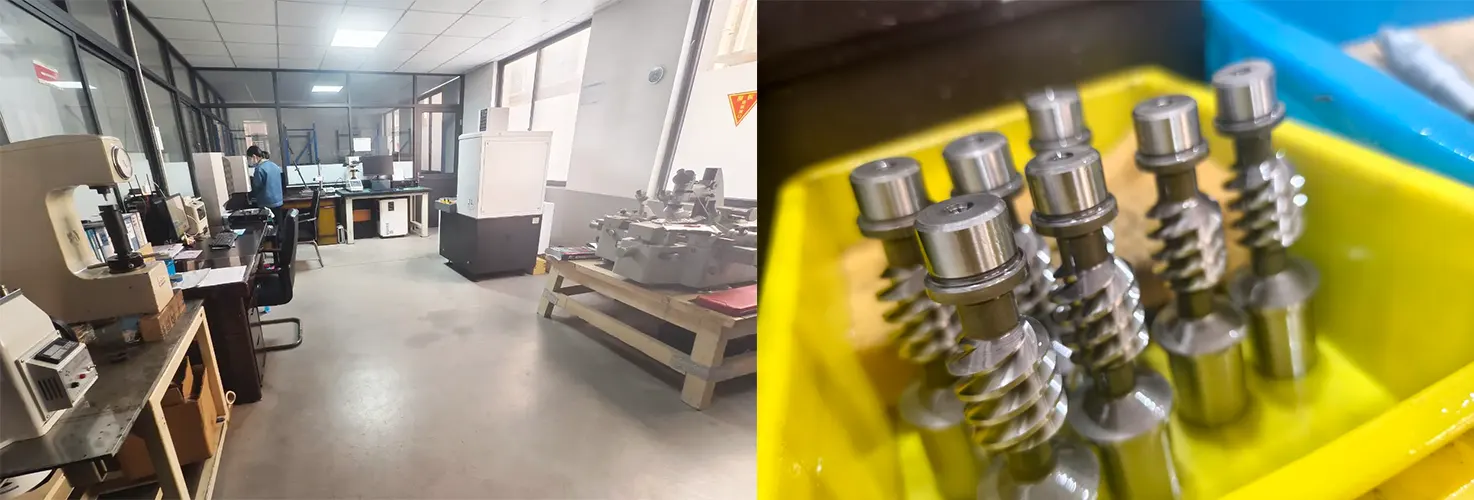

Worm gears play a crucial role in various mechanical systems, providing efficient power transmission and enabling precise speed reduction. Choosing the right supplier is essential to ensure the quality and reliability of these components. GBC, as the Australian sales agent for Ever-power Group, stands out as one of Australia’s leading suppliers and manufacturers of worm gears.

Our product line includes high-quality Brass Worm Wheels, designed for durability and optimal performance in diverse applications. These components are engineered to withstand significant loads while providing smooth operation, making them a preferred choice in the industry.

At GBC, we pride ourselves on our strength and service. Our experienced team is committed to delivering top-notch products and support, ensuring that our clients receive the best solutions tailored to their needs.

Additional information

| Edited | Sylvia |

|---|

The Brass Worm Wheel is a critical component in various mechanical systems, designed to work seamlessly with brass worm gears. Constructed from high-quality brass, this durable wheel provides excellent wear resistance and low friction properties. Its primary function is to transmit motion and torque efficiently between non-intersecting shafts, making it ideal for applications in machinery and automotive systems. The worm gear mechanism allows for smooth operation, enhancing the overall performance of devices utilizing the brass worm wheel.