Electric Worm Gear

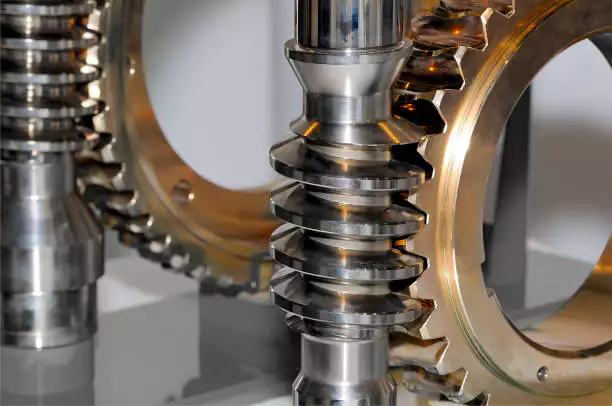

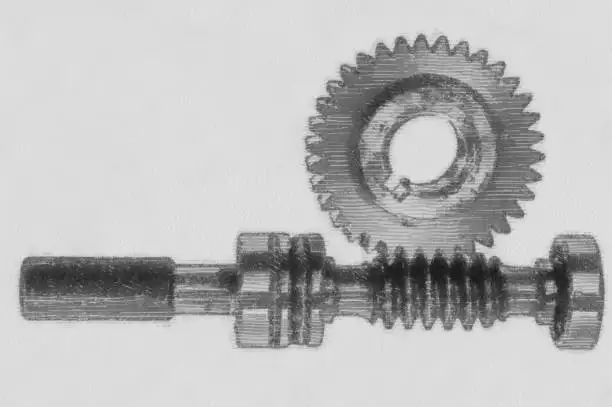

The Electric Worm Gear is an innovative mechanical device designed for efficient power transmission. Comprising a Worm Gear and a Worm Wheel, it effectively converts rotational motion while providing high torque and reduced speed. Made from durable materials like hardened steel or aluminum, the Worm Shaft ensures longevity and reliability. The unique design of the Worm Screw allows for smooth operation, making the Electric Worm Gear ideal for various applications in automation and machinery.

Specifications of Electric Worm Gear

| Specification | Value |

|---|---|

| Input Power | 0.5 - 5 HP |

| Gear Ratio | 5:1 to 100:1 |

| Output Torque | Up to 200 Nm |

| Efficiency | 80% - 90% |

| Operating Temperature | -20°C to 100°C |

| Mounting Type | Foot or Flange Mount |

Features and Advantages of Electric Worm Gear

- High Efficiency: The Electric Worm Gear provides excellent power transmission while minimizing energy loss, thanks to the unique design of the Worm Gear and Worm Wheel.

- Compact Design: Its compact structure allows for installation in tight spaces without compromising performance, making it ideal for various applications.

- Self-locking Mechanism: The Worm Shaft offers a self-locking feature, ensuring stability and safety in operation.

- Durability: Constructed from high-quality materials, the Electric Worm Gear is designed to withstand wear and tear, providing long-lasting performance.

- Versatility: Suitable for various industries, the Worm Screw can be used in applications ranging from machinery to robotics.

Applications of Electric Worm Gear in Modern Machinery

The Electric Worm Gear is an essential component in various mechanical systems, providing efficient power transmission. Utilizing a Worm Gear and Worm Wheel configuration, this gear type excels in applications requiring significant torque and space-saving designs. The Worm Shaft, part of the system, ensures smooth operation and durability, while the Worm Screw facilitates precise movement in machinery. Industries such as automotive, robotics, and material handling benefit from the unique capabilities of Electric Worm Gear, making it a preferred choice for engineers and designers.

Maintenance Tips for Electric Worm Gear

- Regular Lubrication: Proper lubrication is crucial for the longevity of your Electric Worm Gear. The Worm Gear, Worm Wheel, and Worm Shaft experience significant friction during operation. Using the correct lubricant reduces wear and tear, ensuring smooth movement. It is essential to apply lubricant on the Worm Screw at regular intervals, ideally every six months or according to the manufacturer's guidelines. When lubricating, make sure to clean any old grease or dirt from the components to avoid contamination. By maintaining proper lubrication, you can significantly extend the lifespan of your Electric Worm Gear.

- Inspect for Wear and Tear: Regular inspections are vital for identifying any signs of wear in the Worm Gear and its components. Look for unusual noises or vibrations during operation, as these may indicate issues with the Worm Wheel or Worm Shaft. Additionally, check for any visible damage such as cracks or excessive wear on the Worm Screw. If you notice any irregularities, address them immediately to prevent further damage. Regular maintenance checks will help you track the condition of your Electric Worm Gear and make timely repairs, ensuring optimal performance.

- Cleaning the Components: Keeping the Electric Worm Gear clean is essential for its performance. Dust and debris can accumulate on the Worm Gear, Worm Wheel, and Worm Shaft, leading to inefficient operation. Use a soft brush or cloth to gently remove any dirt, ensuring that you do not damage the components. Regular cleaning helps in preventing overheating and maintains the efficiency of the Worm Screw. Make it a habit to clean these parts whenever you conduct your routine inspections, as it can greatly contribute to the gear's durability.

Worm Gear Manufacturer - GBC

Worm gears are essential components in various mechanical systems, providing high torque and efficient power transmission in confined spaces. Choosing the right supplier for worm gears is crucial to ensure optimal performance and longevity of your machinery. GBC, as the Australian sales agent for Ever-power Group, stands out as one of Australia's professional suppliers and manufacturers of worm gears.

At GBC, we specialize in Electric Worm Gears that are designed to meet diverse industrial needs. Our products are engineered for durability and precision, making them suitable for a wide range of applications.

With our deep expertise and commitment to quality, we pride ourselves on delivering exceptional products and services to our clients. Our focus on customer satisfaction ensures that you receive the best solutions tailored to your specific requirements.

Additional information

| Edited | Sylvia |

|---|

The Electric Worm Gear is an innovative mechanical device designed for efficient power transmission. Comprising a Worm Gear and a Worm Wheel, it effectively converts rotational motion while providing high torque and reduced speed. Made from durable materials like hardened steel or aluminum, the Worm Shaft ensures longevity and reliability. The unique design of the Worm Screw allows for smooth operation, making the Electric Worm Gear ideal for various applications in automation and machinery.