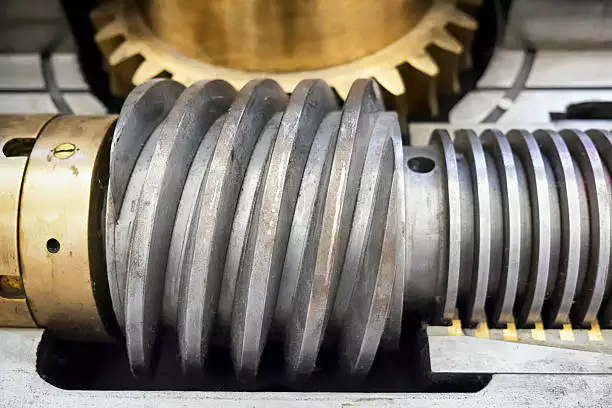

Long Worm Gear

The Long Worm Gear is a specialized mechanical component designed to convert rotational motion efficiently. Made from high-strength materials, it ensures durability and reliability in various applications. This gear system comprises a worm gear, worm wheel, and worm shaft, which work together to provide a high torque output while minimizing space. The Long Worm Gear is ideal for applications requiring precise motion control and is commonly used in machinery, conveyors, and automotive systems, making it an essential part of many engineering solutions.

Specifications of Long Worm Gear

| Parameter | Value |

|---|---|

| Material | High-Strength Steel |

| Gear Ratio | 5:1 |

| Length | 200 mm |

| Diameter | 50 mm |

| Load Capacity | 1000 N |

| Temperature Range | -20°C to 100°C |

Characteristics and Advantages of Long Worm Gear

The Long Worm Gear is designed with precision and durability in mind, making it a superior choice for various mechanical applications. Here are some key features and benefits:

- High Efficiency: The worm gear setup, featuring a worm wheel and worm shaft, ensures smooth and efficient power transmission.

- Compact Design: Its compact structure allows for space-saving installations while providing excellent torque output.

- Low Noise Operation: The design minimizes noise, making it suitable for environments where quiet operation is essential.

- Versatile Applications: The Long Worm Gear can be utilized in diverse fields, from robotics to automotive, due to its adaptability.

- Enhanced Durability: Built with high-quality materials, the worm screw mechanism offers long-lasting performance even under heavy loads.

Applications of Long Worm Gear in Mechanical Systems

The Long Worm Gear is an essential component in various mechanical applications, offering a unique advantage in torque transmission and speed reduction. This gear system consists of a Worm Gear, Worm Wheel, Worm Shaft, and Worm Screw, all working in harmony to deliver efficient performance. The Long Worm Gear is particularly beneficial in scenarios requiring high gear ratios and compact design, making it ideal for industrial machinery, conveyor systems, and automotive applications. By utilizing the Long Worm Gear, engineers can achieve reliable and smooth motion control, enhancing the overall efficiency of their systems.

Maintenance Tips for Long Worm Gear

- Regular Lubrication: To ensure optimal performance and longevity of the Long Worm Gear, regular lubrication is crucial. Using the right type of lubricant minimizes friction between the Worm Gear and Worm Wheel, preventing wear and tear. It's important to select a lubricant that suits the operational conditions of your machinery. Inspect the lubrication levels frequently and replenish as necessary. Proper lubrication not only extends the life of the Worm Shaft and Worm Screw but also enhances overall efficiency, reducing the risk of overheating and mechanical failure.

- Inspect for Wear and Damage: Regular inspection of the Long Worm Gear components is essential for identifying wear and damage early. Pay close attention to the Worm Shaft and Worm Wheel for signs of pitting, scoring, or excessive wear. If any irregularities are noticed, it may be time to replace or repair the affected parts. This proactive approach can prevent costly downtime and ensure that your equipment operates smoothly. Additionally, check the alignment of the gear system to avoid uneven stress that can lead to premature failure.

- Correct Installation and Alignment: Proper installation and alignment of the Long Worm Gear are vital for its performance and durability. Ensure that the Worm Gear and Worm Wheel are aligned accurately to prevent undue stress on the components. Misalignment can lead to increased wear and inefficient operation. Utilize alignment tools during installation, and check periodically to confirm that the system remains correctly aligned. This step will not only extend the lifespan of the Worm Shaft but also enhance the efficiency of the entire gear system.

- Temperature and Environment Monitoring: The operational environment significantly impacts the performance of the Long Worm Gear. High temperatures can lead to accelerated wear and failure. Therefore, monitoring the temperature of the gear system is critical. Establish cooling mechanisms if necessary, and ensure that the surrounding environment is free from contaminants that could affect the gear's performance. By maintaining optimal operating conditions, you can significantly increase the lifespan of the Worm Gear and its associated components.

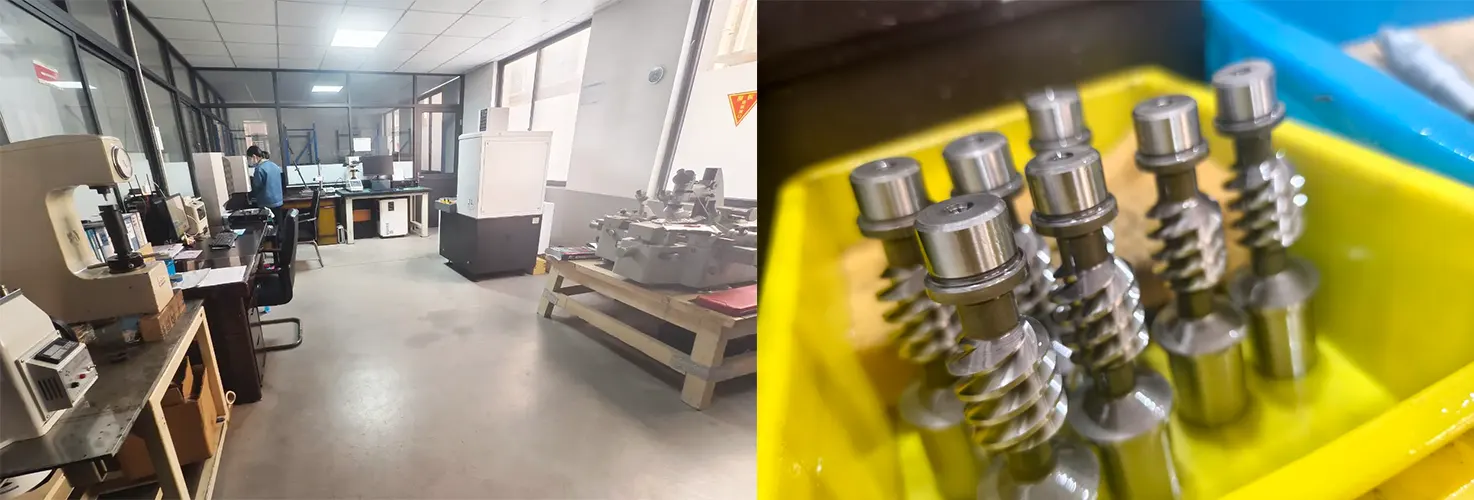

Worm Gear Manufacturer - GBC

Worm gears play a crucial role in the mechanical engineering sector, providing efficient power transmission with high torque output while minimizing space requirements. Selecting the right supplier is essential to ensure quality, reliability, and performance in applications where worm gears are utilized.

GBC is a proud sales agent for Ever-power Group in Australia. We are recognized as one of the leading suppliers and manufacturers of worm gears and worm gear sets in the region. Our extensive experience and commitment to quality make us a trusted choice for many industries.

Our product range includes Long Worm Gears, designed to cater to various industrial applications. These components are engineered for durability and precision, ensuring optimal performance in demanding conditions.

With a strong foundation in quality manufacturing and customer service, GBC stands out for its ability to meet diverse client needs. We are dedicated to providing exceptional products and support, ensuring that our customers receive the best possible solutions for their applications.

Additional information

| Edited | Sylvia |

|---|

The Long Worm Gear is a specialized mechanical component designed to convert rotational motion efficiently. Made from high-strength materials, it ensures durability and reliability in various applications. This gear system comprises a worm gear, worm wheel, and worm shaft, which work together to provide a high torque output while minimizing space. The Long Worm Gear is ideal for applications requiring precise motion control and is commonly used in machinery, conveyors, and automotive systems, making it an essential part of many engineering solutions.