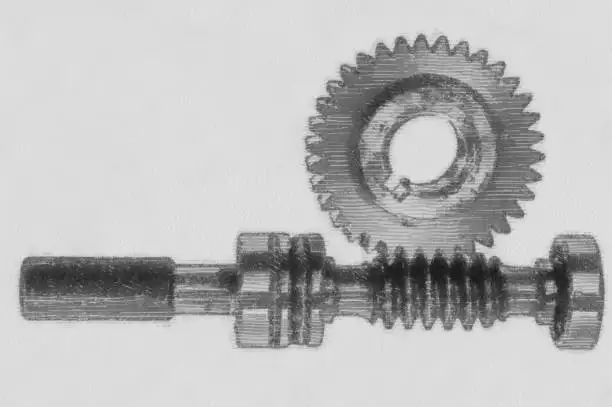

Stepper Worm Gear

The Stepper Worm Gear is an essential component in various mechanical applications, designed to provide efficient speed reduction and high torque output. Composed of durable materials such as brass or steel, the Worm Gear works in conjunction with a Worm Wheel to ensure smooth operation. The Worm Shaft allows for precise movement, while the Worm Screw enhances performance by minimizing backlash. Ideal for automation and robotics, the Stepper Worm Gear is vital for reliable power transmission.

Specifications of Stepper Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 10:1 |

| Max Torque | 5 Nm |

| Input Shaft Diameter | 8 mm |

| Output Shaft Diameter | 12 mm |

| Operating Temperature | -20 to 100 °C |

| Weight | 1.2 kg |

Features and Advantages of Stepper Worm Gear

The Stepper Worm Gear is a remarkable component in mechanical systems, offering several key features and advantages:

- High Torque Output: The Worm Gear design provides significant torque amplification, making it ideal for heavy-load applications.

- Compact Size: The compact nature of the Worm Wheel and Worm Shaft allows for space-saving designs without compromising performance.

- Self-Locking Property: The unique geometry of the Worm Screw ensures that the system remains stable even under load, preventing back driving.

- Smooth Operation: The interaction between the Worm Gear and Worm Wheel results in minimal noise and vibration during operation.

Applications of Stepper Worm Gear in Precision Machinery

The Stepper Worm Gear is an essential component in various precision machinery applications. Utilizing a Worm Gear mechanism, it provides smooth and controlled motion, ideal for robotics, conveyor systems, and automated machinery. The Worm Wheel and Worm Shaft work together to efficiently transfer power with minimal backlash, ensuring high accuracy in motion control. Additionally, the Worm Screw design allows for a compact and durable setup, making it suitable for tight spaces. Overall, the Stepper Worm Gear is crucial for enhancing the performance and reliability of modern mechanical systems.

Maintenance Tips for Your Stepper Worm Gear

- Regular Lubrication: To ensure the longevity of your Stepper Worm Gear, regular lubrication is essential. Use a high-quality lubricant that is compatible with the materials of the Worm Gear and Worm Wheel. Proper lubrication reduces friction between the Worm Shaft and Worm Screw, preventing excessive wear and overheating. Check the lubricant levels frequently and apply as needed to maintain optimal performance. A well-lubricated system not only extends the lifespan of your components but also enhances operational efficiency.

- Periodic Inspections: Schedule periodic inspections of your Stepper Worm Gear to check for signs of wear. Look for any unusual noises or vibrations that may indicate issues with the Worm Shaft or Worm Screw. Inspect the teeth of the Worm Gear and Worm Wheel for any signs of damage, such as chips or excessive wear. Early detection of problems can prevent more significant failures and costly repairs. Document your findings and replace any worn components promptly to maintain the smooth operation of your gear system.

- Temperature Monitoring: Monitor the operating temperature of your Stepper Worm Gear, as excessive heat can lead to premature failure. High temperatures can degrade the lubricant and cause wear on the Worm Gear and Worm Wheel. Use thermal imaging or temperature sensors to keep track of the heat generated during operation. If you notice temperatures exceeding the recommended range, consider improving ventilation or reducing load to prevent damage to the Worm Shaft and Worm Screw.

- Load Management: Ensure that your Stepper Worm Gear operates within its specified load limits. Overloading the Worm Gear can lead to increased stress on the Worm Shaft and Worm Screw, resulting in accelerated wear and potential failure. Always refer to the manufacturer's guidelines for load capacity and adjust your applications accordingly. Implementing proper load management practices will not only prolong the lifespan of your gear but also enhance its overall performance.

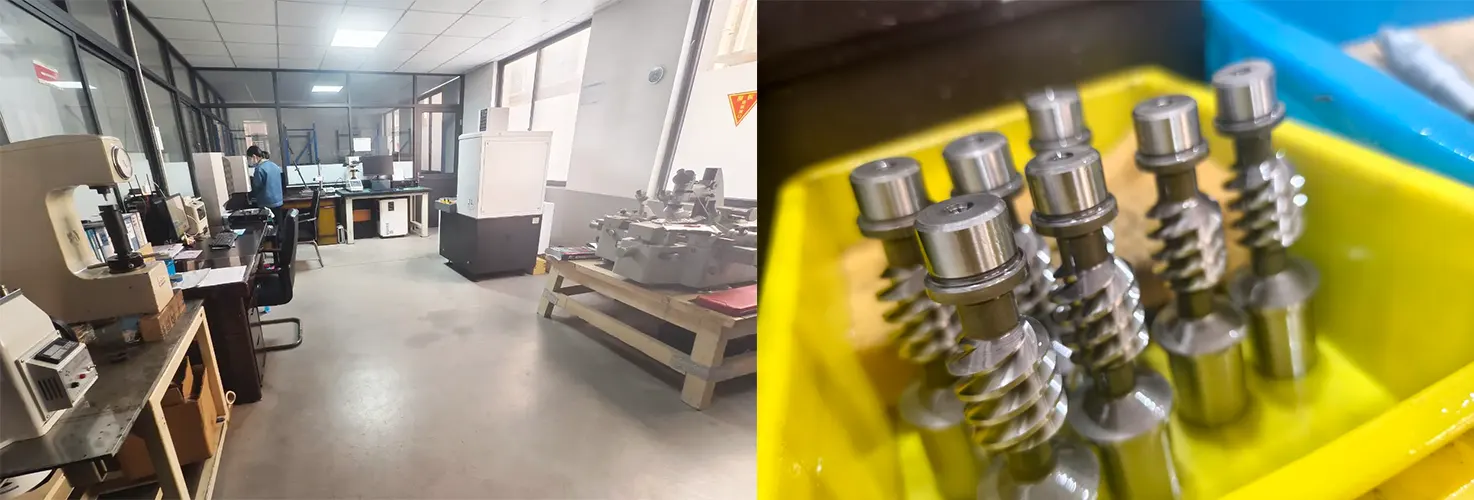

Worm Gear Manufacturer - GBC

Worm gears play a crucial role in various mechanical applications due to their ability to provide high torque and speed reduction while maintaining a compact design. Choosing the right supplier is essential to ensure the quality and performance of these components, as they significantly affect the efficiency of machinery.

GBC serves as the Australian sales agent for Ever-power Group, establishing us as one of the leading suppliers and manufacturers of worm gears in Australia. Our expertise allows us to provide high-quality products tailored to meet diverse industrial needs.

Our product line includes the Stepper Worm Gear, designed to deliver precise motion control and excellent torque transmission. These gears are ideal for applications requiring accurate positioning and reliable performance, making them a favorite among engineers and designers.

At GBC, we pride ourselves on our strength in manufacturing and our commitment to exceptional customer service. Our experienced team is dedicated to supporting our clients with tailored solutions and reliable products to meet their specific requirements.

Additional information

| Edited | Sylvia |

|---|

The Stepper Worm Gear is an essential component in various mechanical applications, designed to provide efficient speed reduction and high torque output. Composed of durable materials such as brass or steel, the Worm Gear works in conjunction with a Worm Wheel to ensure smooth operation. The Worm Shaft allows for precise movement, while the Worm Screw enhances performance by minimizing backlash. Ideal for automation and robotics, the Stepper Worm Gear is vital for reliable power transmission.