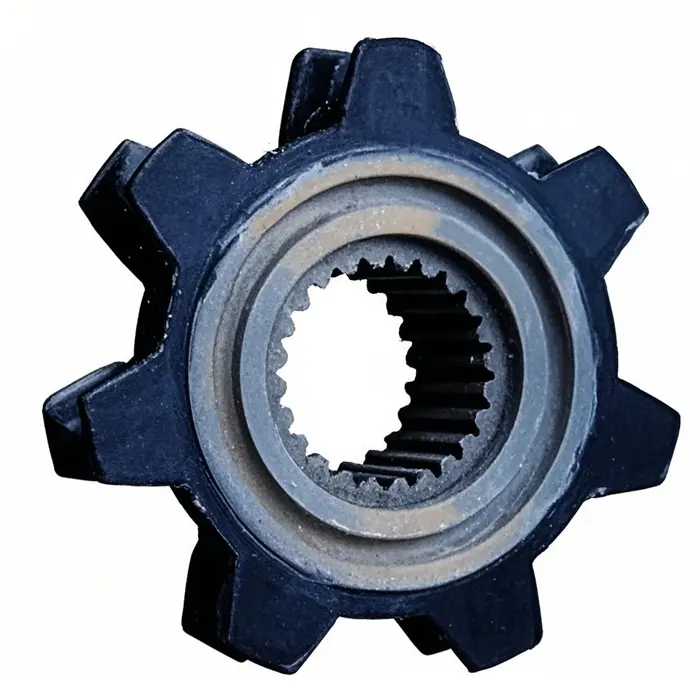

Scraper Sprocket

Scraper sprocket is a type of sprocket specifically designed for scraper conveying systems and is widely used in industries such as agriculture, food processing, mining, and sewage treatment. It achieves efficient material transportation by being used in combination with the scraper chain. Compared with ordinary sprockets, the scraper sprockets produced by our company has stronger wear resistance and corrosion resistance, and are suitable for various complex working conditions.

What Is a Scraper Sprocket Used For?

The scraper sprocket is a key transmission component in the scraper conveying system, mainly used to drive the scraper chain to run along the conveying path. It transmits the rotational power of the motor to the conveyor chain by meshing with the tooth shape of the chain, achieving continuous material transportation. This type of sprocket usually appears in chain-driven systems and is particularly suitable for scenarios where powdery, granular, or moist materials are conveyed, such as grains, ores, sludge, etc.

Compared with the ordinary sprocket, scraper sprocket pays more attention to wear resistance, corrosion resistance, and high load performance in structural design, and can maintain stable operation for a long time in heavy-duty environments. It is an integral part of the scraper conveyor system, which not only enhances the conveying efficiency but also ensures the stable operation of the entire equipment.

What Industries Use Scraper Sprockets?

Scraper sprockets are widely used in multiple key industries that rely on material conveying. Due to its strong adaptability and durability, different industries will choose scraper sprockets of different materials and specifications to meet the requirements of specific working conditions.

- Agricultural machinery: Conveying systems used for bulk materials such as grains and feed, often in conjunction with chain scraper sprockets to achieve efficient handling.

- Food processing: Due to the high requirements for hygiene and anti-corrosion, stainless steel scraper sprockets are usually selected.

- The mining and building materials industry: It is necessary to handle highly abrasive materials and is often equipped with heavy-duty scraper sprockets.

- In water treatment plants, scraper sprockets drive the sludge scraping chain, and the use of corrosion-resistant plastic materials is particularly common.

- Chemical and pharmaceutical industry: custom scraper sprockets can adapt to complex media and corrosive environments.

How to Choose the Right Scraper Sprocket?

Selecting the appropriate scraper sprocket is the key to ensuring the efficient and stable operation of the conveying system. Different application scenarios have different requirements for the design, material and performance of sprocket.

| Chain specification matching | The scraper sprocket must be consistent with the model of the scraper chain being used, and the tooth profile should match to avoid poor operation or accelerated wear. |

| Usage environment | In humid, high-temperature, and corrosive environments, stainless steel or plastic scraper blades should be selected to ensure durability. |

| Load and usage frequency | For high-frequency operation or high-load applications, heavy-duty scraper sprocket should be selected, which has higher strength and wear resistance. |

| Customization requirements | If the equipment structure is special, custom scraper sprockets can be selected, supporting the customization of parameters such as size, number of teeth, and shaft holes. |

In addition, the scraper sprocket maintenance guide provided by the manufacturer should also be referred to to ensure correct installation and regular maintenance, extend the service life and reduce the equipment failure rate.

Structural Features of the Scraper Conveyor Sprocket Shaft Assembly and Lubrication System

The sprocket of the scraper conveyor is integrally forged from alloy steel. The tooth profile is formed by numerical control processing. Tooth surface quenching treatment. The inner hole is a involute spline, which is assembled with the shaft. The power is output by the reducer and transmitted to the sprocket spline through the sprocket shaft, thereby driving the operation of the scraper chain. The sprocket shaft assembly can be disassembled as a whole in the drive part of the machine head for easy maintenance. The sprocket shaft assembly is equipped with a centralized oil tank for thin oil lubrication. The lubricating oil used can enter the sprocket shaft assembly through the hose of the oil tank, which is convenient for refueling and optimizes the internal environment of the sprocket shaft assembly, thereby extending the service life of the shaft assembly.

Scraper Chains and Sprockets

The sprocket assembly of the scraper conveyor, also known as the sprocket shaft assembly, is an indispensable component of the head part of the fully mechanized scraper conveyor and the transfer machine. During the coal mining process, the sprocket drives the chain through the reducer, which in turn drives the scraper to run in the middle trough, thereby achieving the transportation of coal and other materials. The sprocket assembly of the scraper conveyor is divided into various models according to its size and is suitable for the scraper conveyor used in underground coal mines and the scraper transfer machine used in the chute.

The scraper conveyor sprocket assembly can be classified into the head sprocket shaft assembly and the tail sprocket shaft assembly according to the usage position. The sprocket and chain of the scraper conveyor are the main transmission components in the scraper conveyor, and together they form the transmission mechanism of the scraper conveyor. The sprocket assembly is an important component of the entire mining scraper conveyor, and the drive sprocket (referred to as the sprocket) is the most crucial accessory among them. Therefore, the design of the sprocket has a vital impact on the transmission performance of the conveyor.

At present, the main type of scraper conveyor used is the circular scraper chain. When transporting coal mines driven by sprockets, all the dimensions and models of the driving sprockets should be standard to ensure reliability during use.

Additional information

| Edited | Sylvia |

|---|

Scraper sprocket is a type of sprocket specifically designed for scraper conveying systems and is widely used in industries such as agriculture, food processing, mining, and sewage treatment. It achieves efficient material transportation by being used in combination with the scraper chain. Compared with ordinary sprockets, the scraper sprockets produced by our company has stronger wear resistance and corrosion resistance, and are suitable for various complex working conditions.