Steel Helical Tetragon Milled Tempered & Quenched Gear Rack

The CHTMQ series steel Helical Tetragon Milled Tempered & Quenched Gear Rack by GBC is engineered for precision and durability, making it an ideal choice for various industrial applications. Its unique helical design enhances load distribution, reducing wear and increasing efficiency. As a trusted manufacturer, GBC ensures top-notch quality through advanced tempering and quenching processes. By choosing GBC, suppliers can invest in a reliable gear rack that maximizes performance and longevity, essential for modern machinery.

Introduction

The Steel Helical Tetragon Milled Tempered & Quenched Gear Rack is engineered from high-quality tempered steel, ensuring durability and strength. Its unique helical tetragon tooth profile provides enhanced load distribution, minimizing wear and maximizing efficiency. This gear rack is ideal for precision applications in industrial automation, robotics, and machinery. Our product stands out due to its superior manufacturing process, which guarantees consistent performance and reliability. Additionally, we offer customized solutions to meet specific requirements, ensuring that our gear racks are the perfect fit for various operational needs.

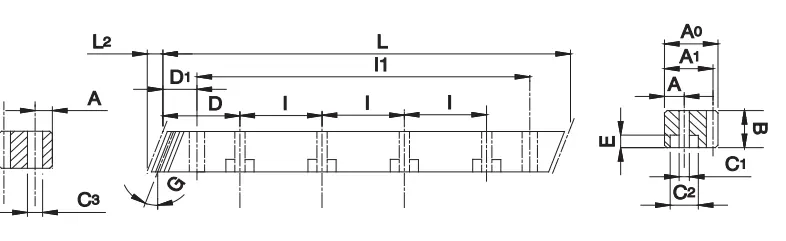

Product Specifications

Manufacturing Description:

Precision Grade:DIN 8e27

Material:S45C

Type:Helical Rack

Treatment of Teeth:Milled

Hardness:Qucnched:HRC18~20 Degree

Sides Ground:not Included

Right Hand Angle:19°31'42”

Pressure angle:20 degree.

Total Pitch Error:0.1mm/1000mm

| 型号 Code |

模数 Module |

L | L2 | 齿数 Tooth No. |

B | A0 | A1 | D | I | 孔数 Hole No. |

A | C1 | C2 | E | D1 | I1 | C3 | ||

| CHTMQ | 010 | 05 | 1 | 500.00 | 3.14 | 150 | 15 | 15 | 14 | _ | _ | _ | _ | _ | _ | _ | _ | _ | _ |

| CHTMQ | 015 | 05 | 1.5 | 500.00 | 6.7 | 100 | 19 | 19 | 17.5 | 62.5 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| CHTMQ | 015 | 10 | 1.5 | 1000.00 | 6.7 | 200 | 19 | 19 | 17.5 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| CHTMQ | 020 | 05 | 2 | 500.00 | 8.9 | 75 | 24 | 24 | 22 | 62.5 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| CHTMQ | 020 | 10 | 2 | 1000.00 | 8.9 | 150 | 24 | 24 | 22 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| CHTMQ | 030 | 05 | 3 | 500.00 | 10.6 | 50 | 29 | 29 | 26 | 62.5 | 125 | 4 | 9 | 10 | 15 | 9 | 35.0 | 430.0 | 7.7 |

| CHTMQ | 030 | 10 | 3 | 1000.00 | 10.6 | 100 | 29 | 29 | 26 | 62.5 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 |

| CHTMQ | 040 | 05 | 4 | 506.67 | 14.2 | 38 | 39 | 39 | 35 | 62.5 | 125 | 4 | 12 | 10 | 15 | 9 | 33.3 | 433.0 | 7.7 |

| CHTMQ | 040 | 10 | 4 | 1000.00 | 14.2 | 75 | 39 | 39 | 35 | 62.5 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 |

| CHTMQ | 050 | 05 | 5 | 500.00 | 17.4 | 30 | 49 | 39 | 34 | 62.5 | 125 | 4 | 12 | 14 | 20 | 13 | 37.5 | 425.0 | 11.7 |

| CHTMQ | 050 | 10 | 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.5 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 |

| CHTMQ | 060 | 05 | 6 | 500.00 | 20.9 | 25 | 59 | 49 | 43 | 62.5 | 125 | 4 | 16 | 18 | 26 | 17 | 37.5 | 425.0 | 15.7 |

| CHTMQ | 060 | 10 | 6 | 1000.00 | 20.9 | 50 | 59 | 49 | 43 | 62.5 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 |

| CHTMQ | 080 | 05 | 8 | 480.00 | 28.0 | 18 | 79 | 79 | 71 | 60.0 | 120 | 4 | 25 | 22 | 33 | 21 | 120.0 | 240.0 | 19.7 |

| CHTMQ | 080 | 10 | 8 | 960.00 | 28.0 | 36 | 79 | 79 | 71 | 60.0 | 120 | 8 | 25 | 22 | 33 | 21 | 120.0 | 720.0 | 19.7 |

| CHTMQ | 100 | 10 | 10 | 1000.00 | 35.11 | 30 | 99 | 99 | 89 | 62.5 | 125 | 8 | 32 | 33 | 48 | 32 | 125.0 | 750.0 | 19.7 |

Applications

The Steel Helical Tetragon Milled Tempered & Quenched Gear Rack is widely utilized in various industrial applications, particularly in automation and machinery. Its unique helical design allows for smooth and efficient power transmission, making it ideal for use in CNC machines, robotic arms, and conveyor systems. The tempered and quenched treatment enhances its durability and resistance to wear, ensuring longevity in demanding environments. This gear rack is essential in precision engineering, providing reliable performance in applications that require high accuracy and load-bearing capabilities.

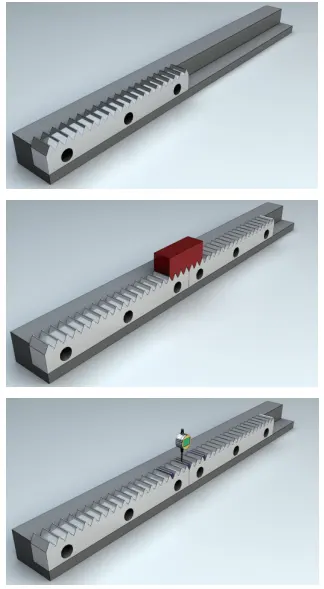

Assembly Instruction

The Steel Helical Tetragon Milled Tempered & Quenched Gear Rack can be assembled to any desired length by connecting multiple racks together. When assembling, it is crucial to adjust the gap between two racks to ensure proper engagement of the tooth spacing. The installation process requires the use of locating pins to secure the racks accurately.

- First, position and fasten the gear rack securely in place.

- Next, use a reverse tooth gauge to position the next gear rack accurately.

- Finally, check each connection individually and utilize a gauge pin to measure the parallelism of the gear racks.

By following these steps carefully, you can ensure optimal performance and longevity of your gear rack assembly.

Why Choose GBC Gear Racks

GBC is the Australian sales agent for Ever-power, a company with nearly 20 years of experience in the gear rack manufacturing industry. Over the years, Ever-power has gradually established and perfected an internationally leading scientific management system for product production and quality inspection, ensuring high quality and cost-effective products. The gear racks produced by the company can achieve a precision level of up to grade 5 according to the German DIN3962 standard, with a maximum single gear rack length of 3200mm. We can manufacture various specifications of straight and helical gear racks from 1 to 22 modules based on customer requirements.

Our Steel Helical Tetragon Milled Tempered & Quenched Gear Rack offers exceptional strength and durability, making it suitable for various applications in demanding environments.

Additionally, our company prides itself on providing excellent customer service, ensuring that all inquiries and needs are addressed promptly and effectively.

The CHTMQ series steel Helical Tetragon Milled Tempered & Quenched Gear Rack by GBC is engineered for precision and durability, making it an ideal choice for various industrial applications. Its unique helical design enhances load distribution, reducing wear and increasing efficiency. As a trusted manufacturer, GBC ensures top-notch quality through advanced tempering and quenching processes. By choosing GBC, suppliers can invest in a reliable gear rack that maximizes performance and longevity, essential for modern machinery.