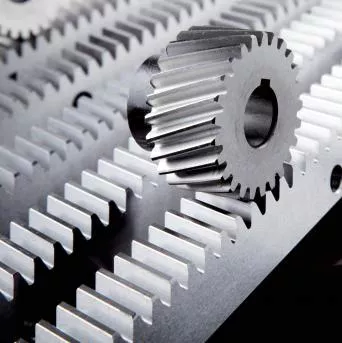

Ground Hardened Straight Tetragonal Chromium Molybdenum Alloy Steel(SCM4401) Gear Rack

The GBC Ground Hardened Straight Tetragonal Chromium Molybdenum Alloy Steel (SCM4401) Gear Rack MSTGH series offers exceptional strength and durability, making it an ideal choice for high-load applications. Its precise design ensures optimal performance, reducing wear and tear. As a leading manufacturer, we prioritize quality and reliability, ensuring that our gear racks meet the highest industry standards. Experience enhanced efficiency and longevity with GBC’s superior engineering.

Introduction

The Ground Hardened Straight Tetragonal Chromium Molybdenum Alloy Steel (SCM4401) Gear Rack is engineered for superior strength and durability. Its unique tetragonal shape optimizes performance in various applications, including robotics and automation. Made from high-quality SCM4401 alloy steel, this gear rack offers excellent wear resistance and precision. Our products stand out due to their consistent quality, attention to detail, and the ability to withstand heavy loads, ensuring reliability in demanding environments.

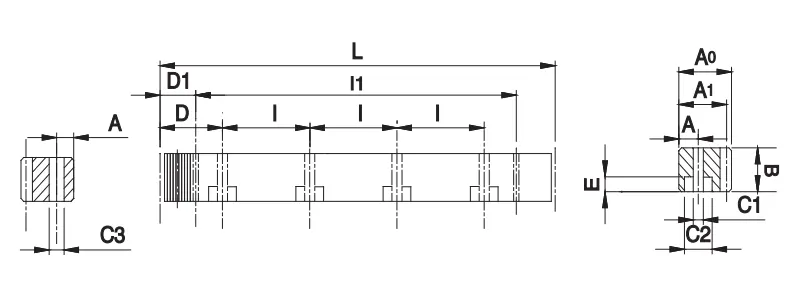

Product Specifications

| 型号 Code |

模数 Module |

L | 齿数 Tooth No. |

B | A0 | A1 | D | I | 孔数 Hole No. |

A | C1 | C2 | E | D1 | 1 | C3 | ||

| MSTGH | 010 | 05 | 1 | 499.51 | 159 | 15 | 15 | 14 | _ | _ | _ | _ | _ | _ | _ | _ | _ | _ |

| MSTGH | 015 | 05 | 1.5 | 499.51 | 106 | 19 | 19 | 17.5 | 62.44 | 124.88 | 4 | 8 | 7 | 11 | 7 | 29.0 | 441.5 | 5.7 |

| MSTGH | 015 | 10 | 1.5 | 999.03 | 212 | 19 | 19 | 17.5 | 62.44 | 124.88 | 8 | 8 | 7 | 11 | 7 | 29.0 | 941.0 | 5.7 |

| MSTGH | 020 | 05 | 2 | 502.65 | 80 | 24 | 24 | 22 | 62.83 | 125.66 | 4 | 8 | 7 | 11 | 7 | 31.3 | 440.1 | 5.7 |

| MSTGH | 020 | 10 | 2 | 1005.31 | 160 | 24 | 24 | 22 | 62.83 | 125.66 | 8 | 8 | 7 | 11 | 7 | 31.3 | 942.7 | 5.7 |

| MSTGH | 030 | 05 | 3 | 508.94 | 54 | 29 | 29 | 26 | 63.62 | 127.23 | 4 | 9 | 10 | 15 | 9 | 34.4 | 440.1 | 7.7 |

| MSTGH | 030 | 10 | 3 | 1017.88 | 108 | 29 | 29 | 26 | 63.62 | 127.23 | 8 | 9 | 10 | 15 | 9 | 34.4 | 949.1 | 7.7 |

| MSTGH | 040 | 05 | 4 | 502.65 | 40 | 39 | 39 | 35 | 62.83 | 125.66 | 4 | 12 | 10 | 15 | 9 | 37.5 | 427.7 | 7.7 |

| MSTGH | 040 | 10 | 4 | 1005.31 | 80 | 39 | 39 | 35 | 62.83 | 125.66 | 8 | 12 | 10 | 15 | 9 | 37.5 | 930.3 | 7.7 |

| MSTGH | 050 | 05 | 5 | 502.65 | 32 | 49 | 39 | 34 | 62.83 | 125.66 | 4 | 12 | 14 | 20 | 13 | 30.1 | 442.4 | 11.7 |

| MSTGH | 050 | 10 | 5 | 1005.31 | 64 | 49 | 39 | 34 | 62.83 | 125.66 | 8 | 12 | 14 | 20 | 13 | 30.1 | 945 | 11.7 |

| MSTGH | 060 | 05 | 6 | 508.94 | 27 | 59 | 49 | 43 | 63.62 | 127.23 | 4 | 16 | 18 | 26 | 17 | 31.4 | 446.1 | 15.7 |

| MSTGH | 060 | 10 | 6 | 1017.88 | 54 | 59 | 49 | 43 | 63.62 | 127.23 | 8 | 16 | 18 | 26 | 17 | 31.4 | 955.0 | 15.7 |

| MSTGH | 080 | 05 | 8 | 502.65 | 20 | 79 | 79 | 71 | 62.83 | 125.66 | 4 | 25 | 22 | 33 | 21 | 26.6 | 449.5 | 19.7 |

| MSTGH | 080 | 10 | 8 | 1005.31 | 40 | 79 | 79 | 71 | 62.83 | 125.66 | 8 | 25 | 22 | 33 | 21 | 26.6 | 952 | 19.7 |

| MSTGH | 100 | 10 | 10 | 1005.31 | 32 | 99 | 99 | 89 | 62.83 | 125.66 | 8 | 32 | 33 | 48 | 32 | 125.7 | 753.96 | 19.7 |

Product Features

- Precision Grade: DIN 6h25 ensures high accuracy and reliability.

- Material: Made from SCM440 Chromium Molybdenum Alloy Steel (42CrMo4) for enhanced durability.

- Type: Straight Rack design for efficient power transmission.

- Treatment of Teeth: Ground teeth for improved surface finish and operational efficiency.

- Hardness: Heat treated to achieve a hardness range of 50-55 degrees.

- Pressure Angle: 20 degrees for optimized meshing with gears.

- Total Pitch Error: Exceptional precision with a total pitch error of just 0.036mm/1000mm.

Troubleshooting Common Issues

The Ground Hardened Straight Tetragonal Chromium Molybdenum Alloy Steel (SCM4401) Gear Rack is known for its durability and strength. However, like any mechanical part, it may encounter certain issues during operation. Below are some common faults and their respective solutions:

- Wear and Tear: Over time, the gear rack may experience significant wear, especially in high-usage applications. Regular maintenance and lubrication can help reduce this issue. If wear is excessive, consider replacing the worn gear rack with a new one.

- Misalignment: If the gear rack is not properly aligned with the mating components, it can lead to uneven wear and increased friction. Check the installation and ensure proper alignment. Adjust and realign as necessary.

- Corrosion: Exposure to moisture or harsh chemicals can lead to corrosion of the gear rack. To prevent this, ensure that the gear rack is coated or treated with corrosion-resistant materials. If corrosion is present, clean the affected areas and apply protective coatings.

- Noise and Vibration: Excessive noise or vibration can indicate a problem with the gear rack's operation. This may be caused by loose fittings or damaged teeth. Inspect for loose bolts and tighten them; replace any damaged components as needed.

Why Gears and Racks are Important?

When it comes to the engagement of gears and racks, particularly with high-quality materials like Ground Hardened Straight Tetragonal Chromium Molybdenum Alloy Steel (SCM4401), there are several key factors to consider. Proper alignment is crucial, as even a slight misalignment can lead to increased wear and tear, resulting in premature failure of both the gear rack and the gears themselves. Additionally, lubrication plays a vital role in reducing friction and enhancing the longevity of the engagement.

The importance of these components cannot be overstated. Gear racks provide linear motion and transform rotational motion into linear force, making them essential in various applications such as automation, robotics, and machinery. The durability and strength of SCM4401 steel ensure that the gear rack can withstand heavy loads and resist deformation, which is essential for maintaining precision in mechanical systems.

Why Choose GBC Gear Racks

GBC is the Australian sales agent for Ever-power, offering high-quality drive components at competitive prices. Our products are currently available in New South Wales, Victoria, and Queensland, covering major cities such as Sydney, Melbourne, Brisbane, Adelaide, and Perth.

Ever-power boasts nearly 20 years of expertise in the industry. Our gear racks achieve a precision grade of up to 5 according to the German DIN3962 standard, with a maximum single length of 3200mm. We can manufacture various specifications of straight and helical gear racks ranging from 1 to 22 modulus, tailored to customer requirements.

Our Ground Hardened Straight Tetragonal Chromium Molybdenum Alloy Steel (SCM4401) Gear Rack is designed for durability and high performance, ensuring outstanding reliability in various applications.

We pride ourselves on providing exceptional customer service, ensuring that all your needs and inquiries are addressed promptly and professionally.

The GBC Ground Hardened Straight Tetragonal Chromium Molybdenum Alloy Steel (SCM4401) Gear Rack MSTGH series offers exceptional strength and durability, making it an ideal choice for high-load applications. Its precise design ensures optimal performance, reducing wear and tear. As a leading manufacturer, we prioritize quality and reliability, ensuring that our gear racks meet the highest industry standards. Experience enhanced efficiency and longevity with GBC’s superior engineering.