Milled Tempered & Quenched Helical Tetragonal Chromium Molybdenum Alloy Steel(SCM4405) Gear Rack

The GBC Milled Tempered & Quenched Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4405) gear rack MHTMQ series offers exceptional strength and durability, making it an ideal choice for demanding applications. With its advanced engineering, this gear rack ensures precision and efficiency in mechanical systems. Manufacturers seeking reliable and high-performance components will find GBC’s SCM4405 gear rack to be a superior solution that enhances operational longevity and reduces maintenance costs.

Introduction

The Milled Tempered & Quenched Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4405) Gear Rack is designed for durability and precision. This gear rack features a helical tooth design, providing smooth operation and reduced noise. Ideal for high-load applications, it excels in automotive and industrial machinery. Our products stand out due to their superior strength, resistance to wear, and excellent dimensional stability, ensuring long-lasting performance in demanding environments.

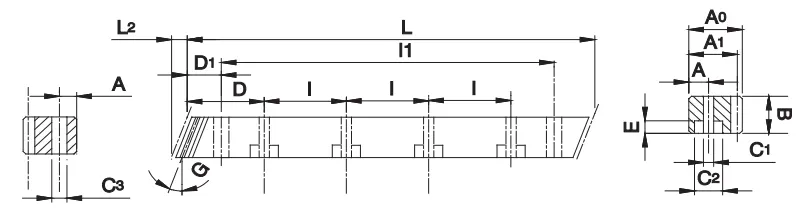

Product Parameters

| Manufacturing Description: |

| Precision Grade:DIN 8e27 |

| Material:(SCM440 Chromium Molybdenum Alloy Steel)42CrMo4 |

| Type:Helical Rack |

| Treatment of Teeth:Milled |

| Hardness:Quenched;HRC21~24 Degree |

| Sides ground:not included |

| Right Hand Angle:19°31'42” |

| Pressure Angle:20 Degree |

| Total pitch error:0.1mm/1000mm |

| 型号 Code |

模数 Module |

L | L2 | 齿数 Tooth No. |

B | A0 | A1 | D | I | 孔数 Hole No |

A | C1 | C2 | E | D1 | 11 | C3 | ||

| MHTMQ | 010 | 05 | 1 | 500.00 | 5.35 | 150 | 15 | 15 | 14 | _ | _ | _ | _ | _ | _ | _ | _ | _ | _ |

| MHTMQ | 015 | 05 | 1.5 | 500.00 | 6.7 | 100 | 19 | 19 | 17.5 | 62.5 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| MHTMQ | 015 | 10 | 1.5 | 1000.00 | 6.7 | 200 | 19 | 19 | 17.5 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| MHTMQ | 020 | 05 | 2 | 500.00 | 8.9 | 75 | 24 | 24 | 22 | 62.5 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| MHTMQ | 020 | 10 | 2 | 1000.00 | 8.9 | 150 | 24 | 24 | 22 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| MHTMQ | 030 | 05 | 3 | 500.00 | 10.6 | 50 | 29 | 29 | 26 | 62.5 | 125 | 4 | 9 | 10 | 15 | 9 | 35.0 | 430.0 | 7.7 |

| MHTMQ | 030 | 10 | 3 | 1000.00 | 10.6 | 100 | 29 | 29 | 26 | 62.5 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 |

| MHTMQ | 040 | 05 | 4 | 506.67 | 14.2 | 38 | 39 | 39 | 35 | 62.5 | 125 | 4 | 12 | 10 | 15 | 9 | 33.3 | 433.0 | 7.7 |

| MHTMQ | 040 | 10 | 4 | 1000.00 | 14.2 | 75 | 39 | 39 | 35 | 62.5 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 |

| MHTMQ | 050 | 05 | 5 | 500.00 | 17.4 | 30 | 49 | 39 | 34 | 62.5 | 125 | 4 | 12 | 14 | 20 | 13 | 37.5 | 425.0 | 11.7 |

| MHTMQ | 050 | 10 | 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.5 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 |

| MHTMQ | 060 | 05 | 6 | 500.00 | 20.9 | 25 | 59 | 49 | 43 | 62.5 | 125 | 4 | 16 | 18 | 26 | 17 | 37.5 | 425.0 | 15.7 |

| MHTMQ | 060 | 10 | 6 | 1000.00 | 20.9 | 50 | 59 | 49 | 43 | 62.5 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 |

| MHTMQ | 080 | 05 | 8 | 480.00 | 28.0 | 18 | 79 | 79 | 71 | 60.0 | 120 | 4 | 25 | 22 | 33 | 21 | 120.0 | 240.0 | 19.7 |

| MHTMQ | 080 | 10 | 8 | 960.00 | 28.0 | 36 | 79 | 79 | 71 | 60.0 | 120 | 8 | 25 | 22 | 33 | 21 | 120.0 | 720.0 | 19.7 |

| MHTMQ | 100 | 10 | 10 | 1000.00 | 35.11 | 30 | 99 | 99 | 89 | 62.5 | 125 | 8 | 32 | 33 | 48 | 32 | 125.0 | 750.0 | 19.7 |

Applications

The Milled Tempered & Quenched Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4405) Gear Rack is widely used in various industrial applications due to its exceptional strength and durability. Key applications include:

- Robotics: Provides precise movement and stability in robotic arms and automated machinery.

- Automotive: Essential in gear systems for electric and hybrid vehicles, delivering reliable performance.

- Manufacturing Equipment: Used in CNC machines and conveyor systems for efficient material handling.

- Aerospace: Utilized in aircraft components where lightweight and strength are crucial.

Assembly Instructions

The gear rack can be seamlessly connected to any length. During assembly, it is essential to adjust the gap between the two gear racks to ensure compatibility with the tooth pitch. Positioning pins must be used when installing the gear racks.

- First, position and secure the gear rack firmly in place.

- Next, utilize a reverse tooth gauge to position the next gear rack accurately.

- Finally, check each connection individually, using a feeler gauge to verify the parallelism of the gear racks.

Proper assembly ensures optimal performance and longevity of your gear rack system. Make sure to follow each step carefully and verify measurements to avoid any misalignment.

Gear Rack Engagement with SCM4405

When engaging a gear rack with a gear made from milled, tempered, and quenched helical tetragonal chromium molybdenum alloy steel (SCM4405), there are several important factors to consider to ensure optimal performance and longevity. Proper alignment is crucial; any misalignment can lead to increased wear and potential failure of the gear system. Additionally, the compatibility of the gear's tooth profile with the rack's teeth should be verified, as this directly affects the smoothness and efficiency of the engagement.

The material properties of SCM4405, which include high strength and excellent wear resistance, contribute significantly to the durability of the gear rack. However, it is essential to regularly inspect both the gear and the rack for any signs of wear or damage. Maintaining proper lubrication within the gear system will also enhance its operational efficiency and reduce friction, which can lead to overheating and accelerated wear.

The importance of the gear rack and gear engagement cannot be overstated. They play a vital role in converting rotational motion into linear motion, which is essential in various applications ranging from industrial machinery to automotive systems. A reliable gear rack engagement ensures smooth operation, enhances performance, and extends the life of mechanical systems.

Why Choose GBC Gear Racks

GBC is the Australian sales agent for Ever-power, offering high-quality transmission products at competitive prices. Our gear racks are currently available in New South Wales, Victoria, and Queensland, covering cities such as Sydney, Melbourne, Brisbane, Adelaide, and Perth.

Ever-power boasts nearly 20 years of accumulated experience in the industry. Our gear racks can achieve a precision level of up to 5 according to German DIN3962 standards, with a maximum single length of 3200mm. We can manufacture various specifications of straight and helical gear racks from module 1 to 22 based on customer requirements.

Our Milled Tempered & Quenched Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4405) gear rack is known for its exceptional durability and strength, making it an ideal choice for demanding applications.

We pride ourselves on providing excellent customer service, ensuring that our clients receive the support they need throughout their purchasing journey.

The GBC Milled Tempered & Quenched Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4405) gear rack MHTMQ series offers exceptional strength and durability, making it an ideal choice for demanding applications. With its advanced engineering, this gear rack ensures precision and efficiency in mechanical systems. Manufacturers seeking reliable and high-performance components will find GBC’s SCM4405 gear rack to be a superior solution that enhances operational longevity and reduces maintenance costs.