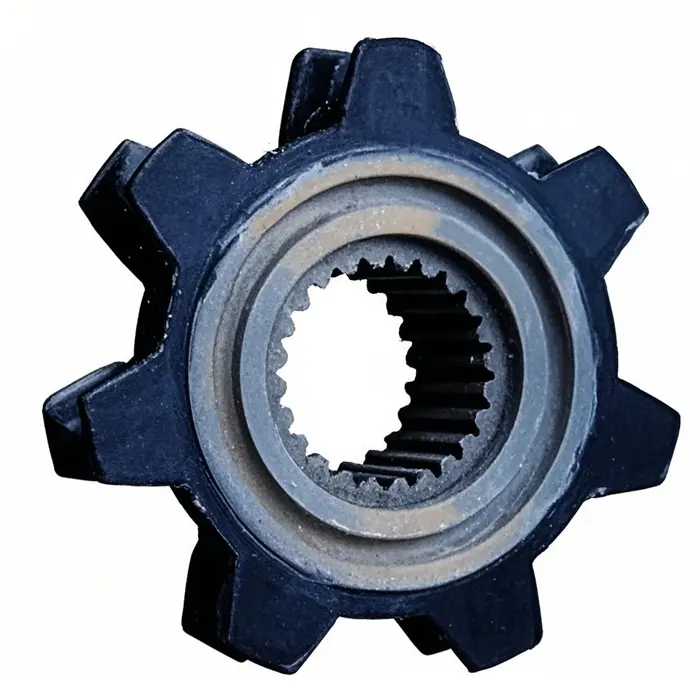

A scraper conveyor is a continuous transportation equipment that conveys bulk materials by means of a moving scraper chain. The SGB-520/22 scraper conveyor is mainly used for transportation in economic common mining faces of medium and low thick coal seams. This product features a compact and simple structure, smooth transmission, convenient installation and maintenance, reliable operation, and flexible process layout. It can not only convey horizontally but also at an incline. It can be used either as a single machine or in combination with multiple units. The sprocket is one of the important components of the scraper conveyor, and its characteristics have a direct impact on the service life of the scraper conveyor. The sprocket drive used in the sprocket wear analysis is a common traction sprocket, which has a relatively large sliding motion at the meshing point. Under harsh working conditions, it will cause relatively severe wear.

The reasons for the severe wear of the scraper sprocket chain socket are as follows:

The greater the adhesive wear load and the higher the surface temperature, the more severe the adhesion phenomenon will be.

For metallic materials of a certain hardness, wear tests conducted under different pressures obtained the curve graph of the relationship between the wear rate and the pressure. When the pressure reaches more than one