Worm Gear and Shaft

Efficient and Durable Worm Gear and Shaft Drive Solutions

Worm Gears for Sale

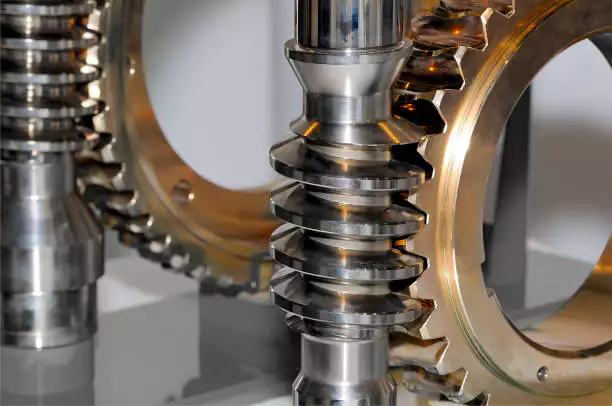

Worm gear and shaft is an efficient and reliable transmission device, which is widely used in various mechanical equipment. It is composed of worm and worm gear. Among them, the worm shaft, also known as worm screw, and the worm wheel, also known as worm gear, achieve power transmission through meshing. This design is renowned for its high reduction ratio, smooth operation and compact structure. Our worm gear set is made of high-quality materials to ensure durability and stability during long-term use.

Our products offer outstanding performance, optimize transmission efficiency and meet a variety of industrial demands.

-

Plastic Worm Gears

-

Worm Gear Shaft

-

Cylindrical Worm Wheel

-

Duplex Worm Gear

-

Brass Worm Wheel

-

Stainless Steel Worm Gear

-

Worm Gear for Solar Tracking

-

Alloy Steel Worm And Worm Gear for Auto Parts

-

Bronze Worm Gear

-

Small Worm Gears

-

Large Worm Gear

-

Steering Worm Gear

-

Throated Worm Gear

-

Double Enveloping Worm Gear

-

Single Enveloping Worm Gear

-

Telescope Worm Gear

-

Electric Motor Worm Gear

-

Electric Worm Gear

-

Globoid Worm Gear

-

Metric Worm Gears

-

Heavy Duty Worm Gear

-

Hollow Worm Gear

-

Hydraulic Worm Gear

-

Long Worm Gear

-

Magnetic Worm Gear

-

Pinion and Worm Gear

-

Precision Worm Gear

-

Reverse Worm Gear

-

Spiral Worm Gear

-

Stepper Worm Gear

Technical Specifications of Worm Shaft and Worm Wheel

Understand the technical details of worm gear and shaft product series and select the configuration that best suits your needs. Our worm gear set offers a variety of specifications, including different modules, tooth numbers and material options, to meet various application scenarios ranging from light loads to heavy loads. The following are some technical parameters of worm and wheel gear:

Materials: High-strength alloy steel, stainless steel or custom materials to enhance the durability of worm shaft and worm gear.

Reduction ratio: From 5:1 to 100:1, meeting the power requirements of different worm gear drive shafts.

Size range: Supports customization of worm wheel shaft and shaft worm gear to meet the installation requirements of various devices.

Surface treatment: Precision grinding and heat treatment to enhance the wear resistance of the worm gear worm wheel.

Our gearbox worm wheel and worm and gear set undergo strict quality control to ensure that each worm gear with shaft can meet industry standards. Need a detailed specification sheet? Please contact us for the complete product catalogue!

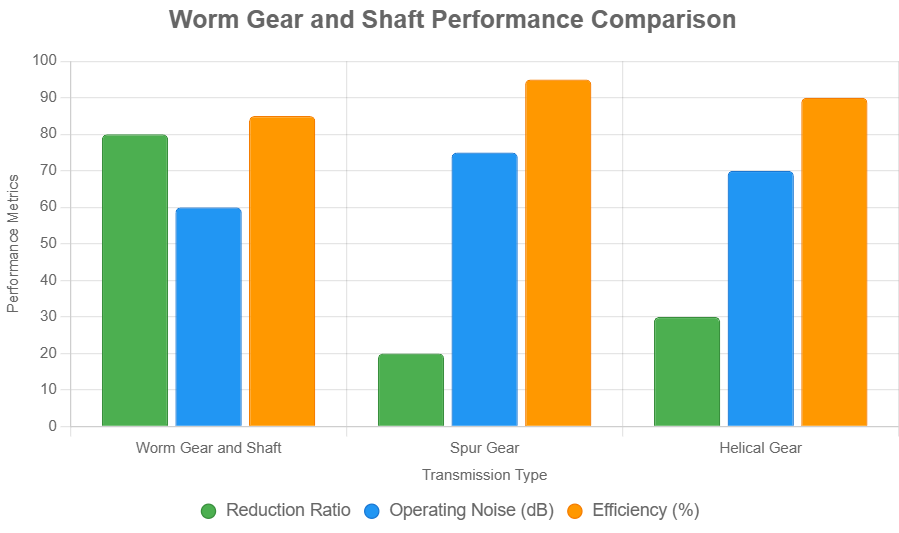

Worm Gear Set and Other Gear Systems

How to Select the Right Worm Gear Drive for Your Application

In industrial automation, mechanical manufacturing and transmission systems, worm gear and worm transmission devices are widely used in various types of equipment due to their advantages such as compact structure, strong self-locking ability and smooth transmission. However, to make the equipment operate efficiently and stably, the correct selection of worm gear drive is a crucial step. The following are the key parameters that need to be focused on when choosing a worm gear drive device to help you find the most suitable WORM GEAR DRIVE solution.

a. Clarify Application Requirements

Before choosing the worm gear drive, its usage scenarios and load requirements should be clarified first. For example:

- What is the maximum torque it can carry?

- Is the self-locking function needed?

- Is the space limited?

- Are there any high temperatures, humidity or corrosive substances in the working environment?

- These factors will directly affect the type, material and size selection of the worm gear drive.

b. Analysis of Core Technical Parameters

- Reduction Ratio

Speed ratio is one of the core indicators of worm gear drive. Different transmission requirements require different speed ratio configurations. Generally speaking, the larger the speed ratio, the slower the output speed and the greater the torque. Common speed ratios include 10:1, 30:1, 60:1, etc. The appropriate configuration should be selected based on the specific working conditions.

- Torque

Torque determines the load capacity that the worm gear drive can withstand. During the selection process, it is essential to ensure that the rated torque of the selected transmission device is higher than the maximum working torque of the equipment to prevent overload damage.

- Efficiency

Although the efficiency of the worm gear drive is relatively low, the operational efficiency can be significantly improved by optimizing the worm gear material (such as bronze) and the lubrication method. For equipment with high performance requirements, it is recommended to choose worm gear drives with ball bearings or double worm structures.

- The installation method matches the size

The installation method of the worm gear drive should match the structure of the equipment. Common installation forms include horizontal, vertical, flange, etc. The choice should be reasonable based on the space of the equipment.

c. Materials and Durability

It is crucial to choose high-quality worm gear drive materials. The common configuration is a steel worm gear combined with a bronze worm wheel. This combination has good wear resistance and is suitable for long-term high-intensity operation. Meanwhile, a high-quality lubrication system can significantly extend the service life of the equipment.

If you still need help, please contact us and our technicians will serve you.

Why Choose Our Worm Gear and Shaft?

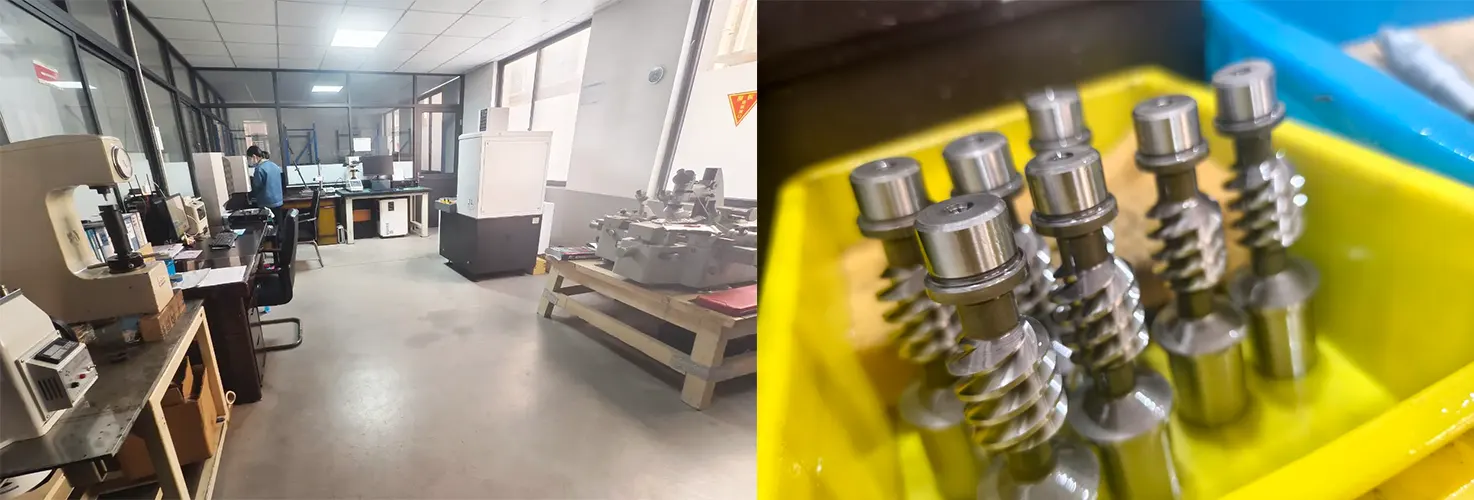

High-precision manufacturing

Our worm gear and shaft adopts advanced production processes to ensure the tooth profile accuracy and surface finish of each worm and worm wheel. This not only improves the transmission efficiency of the worm gear drive shaft, but also significantly reduces the noise and wear during operation. The design of the Gearbox worm wheel has undergone strict testing to ensure a perfect match with the worm shaft and worm gear, providing a smooth operating experience.

Wide range of application fields

Worm and wheel gear is applicable to a variety of industries, including automated equipment, conveying systems, packaging machinery and heavy machinery, etc. Our worm gear set is capable of handling high loads and complex working conditions. Whether it is shaft worm gear or worm wheel shaft, both can provide reliable power support for your equipment. The flexibility of Worm and gear set makes it an ideal choice for many mechanical designs.

Durability and efficiency

By optimizing the material selection of worm gear shaft and worm wheel worm gear, our products have excellent corrosion resistance and wear resistance. The unique design of Worm gear worm wheel ensures a high reduction ratio and low energy consumption, making it perform excellently in energy conservation and environmental protection. Choose our worm and worm gear and you will enjoy long-term stable performance and lower maintenance costs.

Advantages of Our Worm Gears and Shafts

High reduction ratio

The Worm and wheel design provides excellent reduction performance and is suitable for scenarios that require precise control.

Compact structure

The compact design of Worm gear with shaft saves space and is convenient for installation in various devices.

Low-noise operation

The optimized worm shaft and worm wheel reduces vibration and noise, enhancing the comfort of the working environment.

Customized support

We offer worm wheel gear and gear worm wheel in various specifications to meet the needs of different customers.

Frequently Asked Questions

What are the differences between worm & worm gear and traditional gear transmission?

The worm and wheel gear offers a higher reduction ratio and self-locking function through a unique meshing method, making it suitable for applications that require high torque and low speed.

How to choose the suitable worm gear set?

Based on your device load, speed requirements and space limitations, we can recommend the appropriate configurations of worm gear worm wheel and worm gear drive shaft.

What are the maintenance requirements of worm gear with shaft?

Regular lubrication and inspection of the wear of worm shaft and worm gear can ensure long-term efficient operation.

Contact Us for More Information

If you are on the hunt for high-quality worm gear and shaft, or other worm and worm gear products, look no further! Our offerings extend beyond these components; we are also proud to note that our worm gears have made a significant presence in the Australian market. They’ve successfully covered states like New South Wales, Victoria, and Queensland, and are actively selling in major cities such as Sydney, Melbourne, Brisbane, Adelaide, and Perth.

Our team is dedicated to providing you with professional technical support and customized solutions. We’ll ensure that your equipment is equipped with the best worm gear set configuration, tailored to your specific needs. Don’t hesitate to consult with us immediately. Learn more about our worm wheel and worm gear drive shaft offerings, and let us help you optimize your drive system for peak performance!