Essential Requirements for Heavy-duty Uses

The particular requirements of the application must be determined before choosing a drive chain. High torque, high loads, and challenging operating conditions are typical of heavy-duty applications. Important factors to consider:

- Load capacity: How much weight can the drive chain support at its maximum?

- Operating speed: Does the chain run at a safe pace?

- Operating environment: Are there severe elements like dust, corrosion, or high temperatures?

- Equipment type: What kind of machinery, such as an excavator, crane, or conveyor, will use the drive chain?

Drive Chain Types and Application Scenarios

There are numerous varieties of drive chains, each with special benefits and uses. Here are some typical drive chain types:

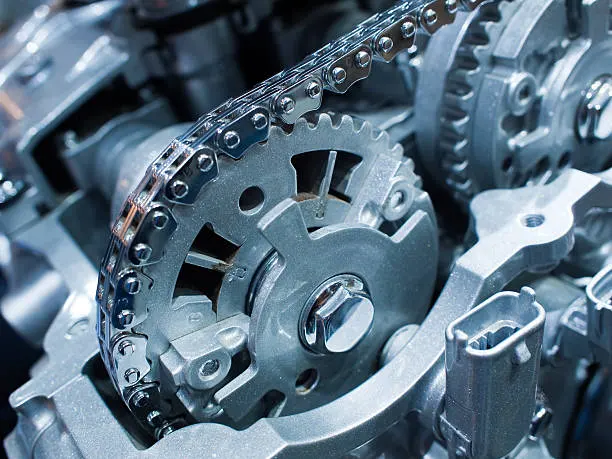

- Roller Chain

The most popular kind of drive chain is the roller chain, which works well for applications requiring modest loads and speeds. Although it is easy and affordable to build, heavy-duty applications could need for more strength and resistance to wear. - Curved Plate Chain

For heavy-duty conveyor systems and lifting equipment, bent plate chain, which is made up of several chain plates and pins, offers exceptional strength and longevity. - Engineering Steel Chain

Engineered steel chains are frequently utilized in mining, metallurgy, and construction because they are made for heavy-duty applications with exceptional strength and fatigue resistance. - Toothed Chain

Powered by teeth meshing, toothed chains are ideal for heavy machinery that has to run smoothly because of their high precision and low noise levels.