Worm gear and worm are a type of gear, often used to transmit motion and power between two interlocking shafts, and are widely applied in various motion and power transmission devices, such as worm gear and worm reducers.

Types of Lubricating Oil for Worm Gears and Worms

At present, the lubricating oils used for worm gears and worms include the following types:

Mineral-based gear oil:

One type is the special lubricating oil for worm gears and worm wheels. This type of gear oil is added with fat additives to provide lubrication for the sliding between the teeth of worm gears and worm wheels, reducing the friction between the tooth surfaces.

Another common type is mineral extreme pressure gear oil (EP), which contains sulfur and phosphorus extreme pressure additives. However, if this type of gear oil comes into contact with copper-containing components, it may cause corrosion. If this type of gear oil is used, it is fine when the temperature is low, but when the temperature is high, it will cause corrosion of copper-containing components. If the gears in contact with the oil do not contain copper, this type of gear oil can be used.

Synthetic gear oils: Mainly include PAO and PAG.

PAO (Polyalphaolefin), also known as polyalphaolefin, has excellent lubricity and is therefore very suitable for applications involving a lot of sliding friction, such as worm gears and worm gears. Similarly, when choosing this type of synthetic oil, remember to check if there are sulfur-phosphorus type extreme pressure additives in the composition.

- PAG (Polyalkylene glycols) polyether synthetic oil also has excellent performance and is gradually becoming popular. The characteristic of PAG is that it is particularly lubricated and completely free of paraffin. At low temperatures, paraffin wax solidifies. The poor fluidity of many mineral oils at low temperatures is due to wax formation. Therefore, PAG synthetic gear oil has excellent low-temperature performance. The main issue with using PAG gear oil is compatibility (whether PAG is compatible with seals, coatings, etc.) When switching to PAG gear oil, is it compatible with the original oil?

Case Analysis

Let’s discuss the selection of worm gear lubricating oil based on the problems that occurred in the worm gear and worm gearbox of a wet grinding machine we once served in a certain enterprise.

Equipment Condition:

The company has 12 wet grinding machines, which are made in the UK and put into use in January 2007. They basically operate 24 hours a day.

The gearbox is driven by worm gear and worm, with a power of 350kw. The input speed of the reducer is 1480r/min, and the output shaft speed is 109r/min. It is equipped with a water cooling system, so the oil temperature will not be too high, and the surrounding environment does not involve water vapor. High-temperature and high-humidity conditions can be disregarded.

Since its commissioning, Mobil SHC320 has been in use.

The equipment has been operating normally all the time.

Problems encountered during lubrication: Pitting corrosion was found in the internal components during the maintenance in April 2009.

|

|

Key Points for Selecting Oil Products

Due to the particularity of the worm gear and worm structure

When the rotation direction of the worm gear is at a right Angle to the rotation direction of the worm wheel that transmits power, and the two tooth surfaces mesh and come into contact, it is almost entirely a sliding contact. High sliding force generates a large amount of friction, so the temperature during the operation of worm gear gearboxes is often higher than that of spur gears and helical gears. Moreover, as the worm gear and worm are vertical, it is relatively difficult to form an oil film on the worm. Therefore, the lubricating oil needs to have good adhesion and excellent lubrication and load-bearing capacity. And it does not contain sulfur and phosphorus type additives. In view of the special circumstances of the equipment, the oil products we select need to meet the following conditions:

It has a relatively high viscosity index to ensure that the viscosity of the oil does not change much under certain temperature variations, thereby maintaining stability

Verify the stability of the oil film.

- Excellent lubrication and load-bearing capacity

- Excellent adhesion ability

- Excellent heat dissipation performance

- Longer lubrication cycle

The effectiveness of worm gear lubricating oil in protecting against wear mainly depends on the selection of base oil rather than the influence of additive formula. The most commonly used worm gear lubricating oil is formulated with the lowest proportion of extreme pressure additives or anti-wear agents.

The common types of lubricating oil for worm gears and worms are as follows:

1) Basic lubricating oil: The lubricating oil is formulated with paraffin base oil, with a minimum viscosity index of 90 to 95.

Advantages:

. The cost is relatively low.

. Considering the simplification of product integration, one product can be shared with other gear oils or circulating oils.

Disadvantages

. The worm gear made of bronze has the highest wear rate – the lifespan of the gear set

The shortest life.

. The operating temperature is relatively high.

. The service life of lubricating oil is relatively short.

Representative oil products are:

. Mobil DTE series products, such as DTE Extra Heavy

. RAYCO (Runyike) GEAR series

2) Superior lubricating oil: The lubricating oil is formulated with synthetic base oil PAO, with a minimum viscosity index of 150

Advantages:

. It has a very high viscosity index and provides excellent oil film stability over a wide range of high and low temperatures.

. Both high and low viscosity grade products are available.

. It has been recognized by quite a number of original manufacturers.

. Reduce the wear rate of the bronze worm gear – increase the service life of the gear set.

. Reduce the operating temperature of the gearbox.

. The lubricating oil has a long service life – up to 3 to 4 times longer than that of ordinary mineral oil.

. Due to the long service life of the lubricating oil and gearbox, the downtime can be reduced.

. Compatible with mineral oil.

. It can be used in many other types of lubrication.

Disadvantage:

. The price of oil is high – but it can be compensated for by the benefits such as the lifespan of the oil, the lifespan of the gearbox, and reduced downtime, etc.

Representative oil products are:

. Mobil SHC 600 series

. Mobilgear SHC XMP series

RAYCO (Runyike) ED series

3) The best choice of lubricating oil: The lubricating oil is formulated with synthetic base oil PAG, and its viscosity index exceeds 200.

Advantages:

. It has the highest viscosity index and can provide the best oil film stability.

. The worm gear made of bronze wears the least – and the gear set has the longest service life.

. Reduce the operating temperature of the gearbox.

. The service life of lubricating oil is long – up to six times longer than that of ordinary mineral oil.

. Reduce the time for downtime and oil changes.

. Improve productivity.

Disadvantage:

. The high price of lubricating oil can be compensated for by increasing the service life of the oil, improving the service life of the gearbox and reducing downtime. . It is not compatible with mineral oil.

Representative oil products are:

. Mobil Glygoyle series, RAYCO SL series.

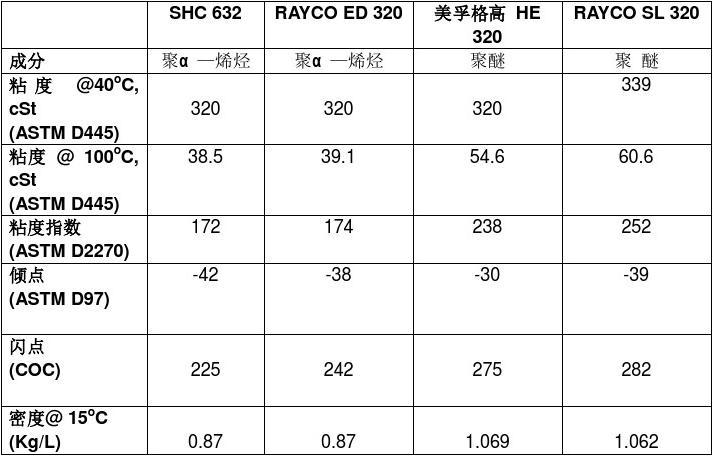

Comparison of Several Gear Oil Parameters

The differences between polyα -olefins and polyethers are reflected as follows:

It can be seen from the above comparison table that the various indicators of RAYCO (Runyike) SL 320 and Mobil Glygoyle HE320 based on polyether (PAG) are significantly higher than those of Mobil SHC320 and RAYCO ED320 based on PAO. Due to the difference in base oils, The viscosity index of polyether components is higher than that of poly – α -olefins. At 100℃, the polyether type shows a higher viscosity, thus having a more stable oil film thickness, and the polyether type has higher high-temperature resistance.

Finally, we recommended to the customer the replacement of PAG type RA YCO (Runyike) SL 320 gear oil. Since the equipment has been in operation, no new pitting corrosion has occurred.

Precautions

When using polyether products, considering their compatibility with other mineral oils or polyalpha-olefin synthetic lubricating oils, to ensure the high performance of the oil and avoid contamination by other oils, which may cause problems such as sludge and foam, please pay attention to cleaning.

When replacing mineral oil or polyα -olefin synthetic lubricating oil with PAG products, the following cleaning measures are required:

Before discharging the old oil, the system should be run to heat it up, and then the old oil should be drained as much as possible. Special attention should be paid to places where old oil is likely to remain, such as the oil tank and pipelines, and at the same time, the oil sludge should be removed. Under no-load conditions, use the minimum amount of PAG gear oil for cleaning. When the system is running, heat up the cleaning oil and then drain it. If necessary, repeat the cleaning to achieve the best effect. Seals and other components need to be inspected. If they are damaged, they must be replaced. When seals soaked in old oil are replaced with PAG gear oil, they may shrink. If possible, it is best to replace them, but it is not mandatory. A detailed inspection can prevent system leakage. It is best to check whether the lubricating oil is contaminated by other materials after one to two days of use.