Mining Chains

GBC delivers unparalleled durability and innovation in heavy-duty mining chains, ensuring maximum uptime and operational efficiency for your surface and underground applications.

30%

Increased Tensile Strength

350%

Greater Corrosion Resistance

24/7

Reliability & Support

Mining Chains Products Catalogue

GBC offers a comprehensive portfolio of mining chains, each meticulously engineered to meet the specific demands of various mining applications.

DA Series Single Strand Conveyor Chains

Exceptional durability for continuous miners, borer miners, and road headers in demanding underground environments.

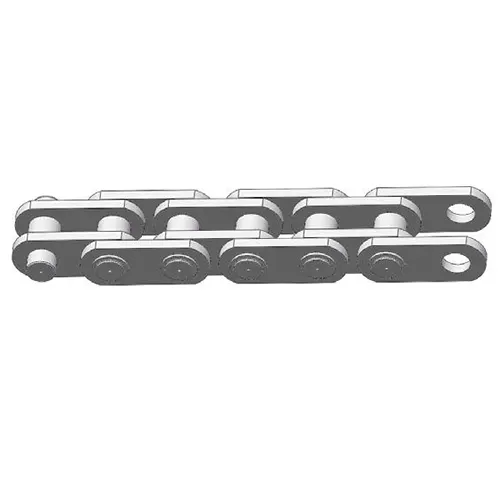

K Series Ladder Conveyor Chains

High-efficiency double-strand scrap chains for rapid material extraction in shuttle cars and feeder breakers.

TC Series Crawler Chains

Extended service life and superior durability for the crawler tracks of underground mining machinery.

AF Series Apron Feeder Chains

Robust, high-impact chains for handling heavy, abrasive, or large-sized materials with controlled flow.

G Series Bucket Elevator Chains

High-strength, fatigue-resistant chains for vertical transportation of bulk materials at fast elevating speeds.

DF Series Drop Forged Chains

Superior strength and wear resistance for conveying abrasive materials like ore and coal in the toughest conditions.

H Series Transmission Chains

Heavy-duty roller chains for power transmission in high-load, high-shock, and abrasive mining environments.

HD Series Heavy Duty Drive Chain

Thickened side plates for increased fatigue resistance and load strength, suitable for low-speed, high-shock applications in heavy equipment and mining environments.

DP Series Deep Pan Conveyor Chain

Heavy-duty chains for horizontal or inclined transport of bulk materials, offering robust construction to handle abrasive loads with durability in mining environments.

O Series Round Link Chain

High-strength steel chains with interconnected round links, designed for underground coal mining to resist abrasion, corrosion, and fatigue in harsh conditions.

Motor Grader Chain

Durable traction chains for motor graders, providing enhanced grip and protection on uneven mining surfaces to improve stability under heavy loads.

Push Coke Chain

Robust drive chains for coking processes, resistant to high temperatures and stress for efficient material pushing with minimal wear in metallurgical operations.

Customised Series Mining Chains

GBC’s Customised Series represents a collaborative approach with mining technology pioneers, providing tailored cutter drive chains, sprockets, and belly conveyor chains to enhance productivity through bespoke solutions. GBC is committed to fostering long-term relationships with clients, built on trust, integrity, and mutual success, striving to exceed customer expectations from initial consultation through to after-sales support.

GBC Customised Series – Key Capabilities & Benefits

The GBC Advantage

Our commitment to quality, innovation, and support ensures your operation runs at peak performance.

Engineering Excellence

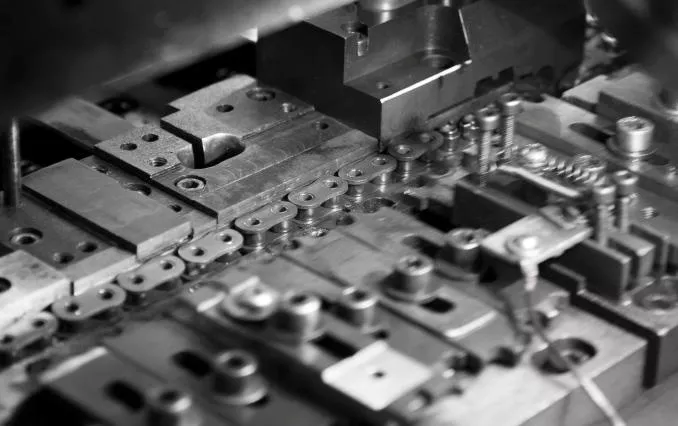

Using premium qualified steels and advanced heat treatments, we produce chains with superior wear resistance and extended service life, verified by rigorous quality control.

Innovation & Customisation

We collaborate with mining technology pioneers to offer fully customised chains, sprockets, and attachments that integrate seamlessly with modern automated systems.

Dedicated Support

Through our Australian agent, we provide responsive local support, fast lead times, and access to technical expertise to minimise downtime and keep your operation moving.

Customer Testimonials

Hear directly from our clients about how our mining chains have transformed their operations.

“Operating in the Pilbara’s extreme heat and abrasive iron ore conditions, our previous conveyor chains often struggled with premature wear and frequent breakages. Since switching to GBC’s heavy-duty chains, we’ve seen a remarkable reduction in downtime. The robust construction and specialized heat treatment truly stand up to the challenge, keeping our operations running smoothly even on the toughest days.”

– Operations Manager, Iron Ore Mine

“The underground environment in our Queensland coal mine presents constant challenges, from dust and moisture to unexpected impacts. GBC’s DA Series conveyor chains have proven exceptionally reliable. Their low operating noise and ease of maintenance have also been a significant benefit for our crews, enhancing both productivity and on-site safety. It’s a noticeable improvement from what we’ve used before.”

– Underground Supervisor, Coal Mine

“When upgrading our feeder breaker system, we needed chains that could handle high-impact loads without constant servicing. GBC’s AF Series apron feeder chains, with their drop-forged links, have exceeded our expectations. The reduced maintenance frequency has translated directly into cost savings and increased throughput, which is vital for our bottom line.”

– Procurement Lead, Mining Contractor

“In our remote site, minimizing equipment failure and simplifying repairs is critical. GBC’s segmental sprockets have made a real difference. The ease of installation and maintenance accessibility means our technicians spend less time in the field on complex repairs, allowing us to get back to production faster. It’s a practical solution for the unique logistics of Australian mining.”

– Maintenance Engineer, Regional Gold Mine

“Our bucket elevators operate continuously, lifting heavy, abrasive minerals, and chain fatigue was a constant concern. GBC’s G Series chains, with their enhanced fatigue resistance, have provided the reliability we needed. We’ve experienced significantly fewer unexpected stoppages, which is paramount for our high-volume processing plant. Their performance has been outstanding.”

– Plant Manager, Lithium Processing Facility

Optimizing Your Operations: A GBC Chain Selection Guide

Choosing the right mining chain is crucial. The following questions help you select the optimal solution for your specific needs.

What is being conveyed or driven?

Identify the type of material (e.g., abrasive, hot, sticky, heavy ore, coal) or the primary function of the chain (e.g., conveying, lifting, driving power, crawling motion). Understanding material properties is crucial for selecting chains with appropriate wear and impact resistance.

Where will the chain operate?

Consider the specific environmental conditions, distinguishing between surface and underground mining operations. Factors such as dust, moisture, corrosive elements, or extreme temperatures (e.g., in coke ovens) must be taken into account.

Why is this chain needed?

Focus on the key performance indicators (KPIs) and strategic objectives of the operation. Is the primary goal increased productivity, enhanced safety, significant cost reduction, or maximized uptime?

When is the chain required for operation and maintenance?

This pertains to the desired operational lifespan of the chain and the planned maintenance intervals. Longer lifespan chains reduce replacement frequency, contributing to cost savings and increased uptime.

Who will be operating and maintaining the equipment?

Consider the human element, including safety considerations for workers and the ease of installation and maintenance for technical personnel. Chains designed for low noise or easy assembly can significantly improve worker well-being and efficiency.

How will the chain integrate with existing machinery?

This involves technical compatibility, including precise dimensions, pitch, and required load capacity. Understanding the installation and maintenance procedures is also vital for seamless integration and long-term operational success.

Installation & Maintenance Best Practices

Proper installation and diligent maintenance are paramount for maximizing the lifespan and performance of your GBC mining chains.

General Guidelines for Longevity

Proper cleaning and maintenance are essential for extending service life, and regular visual inspections are required to identify potential issues early. This proactive approach minimizes unexpected failures and ensures continuous operation.

Comprehensive Technical Support

GBC provides comprehensive “technical support and expertise to assist mining companies with chain selection, installation, and maintenance.” Our knowledgeable team is dedicated to optimizing your chain performance and maximizing equipment uptime.

These design features that simplify maintenance directly address the significant “maintenance costs” and “unplanned downtime” challenges prevalent in Australian mining operations. By providing solutions with a “low maintenance design,” GBC offers substantial value to the industry, contributing to improved operational efficiency and reduced overall cost of ownership.

GBC Design for Simplified Maintenance

- DA Series: Engineered for “less complexity of maintenance” and “easy to install and disassemble,” reducing labor and downtime.

- SD Series: Segmental Sprockets:** Offer “accessibility for maintenance,” allowing for quicker component replacement without extensive disassembly.

- H Series Chains: Feature “self-lubricating” options or are “compatible with advanced lubrication systems” to significantly reduce maintenance frequency and needs.

Troubleshooting Common Chain Issues

Even with the most robust designs, operational challenges can arise. GBC is committed to supporting clients in efficiently resolving common chain issues.

Identifying Common Problems

Common problems observed in mining chains include general wear, the development of cracks, chemical damage, gouging, and other deformations. Chain elongation can also occur over time, particularly in heavy-duty drive chains.

GBC’s Proactive Solutions & Support

GBC’s robust design and selection of high-quality materials are engineered to significantly reduce the incidence of these common issues. Our commitment to quality ensures that our chains are built to withstand the most demanding conditions, minimizing the likelihood of premature failure.

In instances where problems do arise, GBC maintains a responsive support system. Clients are encouraged to “contact our technical department,” which is committed to replying “within 24 hours and provide possible solutions.” This rapid response capability is crucial for Australian mining operations, where minimizing costly downtime is a top priority. By proactively addressing common chain issues through superior product design and offering a clear, responsive support channel, GBC reinforces its trustworthiness and commitment to after-sales service, directly mitigating the financial and operational risks associated with chain failures.

Complementary Products & Integrated Solutions

GBC offers a holistic range of products that complement its mining chain offerings, providing integrated solutions for comprehensive material handling and power transmission systems.

Sprockets

GBC manufactures high-quality sprockets, including the SD Series Segmental Sprockets, designed for easy installation and maintenance. These are crucial for efficient operation of all chain-driven systems.

Conveyor Components

Beyond chains, GBC’s expertise extends to components that support the entire conveyor system, including various flight bar designs and attachment options that work seamlessly with GBC conveyor chains.

Power Transmission Systems

For heavy-duty drive applications, GBC’s H Series and HD Series chains are complemented by a range of power transmission components, ensuring a complete and reliable power transfer solution.

Custom Engineered Solutions

GBC’s Customised Series highlights our ability to develop bespoke components beyond standard chains and sprockets, including specialized attachments and unique link designs for highly specific mining applications.

FAQs

Find quick answers to common questions about GBC mining chains and our services.

Q1: What types of mining chains does GBC offer?

A1: GBC offers a comprehensive range of heavy-duty mining chains, including DA Series single strand conveyor chains, K Series ladder conveyor chains, TC Series crawler chains, AF Series apron feeder chains, DP Series deep pan conveyor chains, O Series round link chains, G Series bucket elevator chains, DF Series drop forged chains, H Series transmission chains, HD Series heavy-duty drive chains, Motor Grader chains, and Push Coke chains. We also specialize in customized solutions.

Q2: How do GBC chains withstand the harsh mining environment?

A2: GBC chains are engineered with features specifically designed for extreme conditions. This includes the use of selected premium qualified steels, special heat-treated pins for enhanced wear resistance, robust durability against abrasion and impact, and specialized coatings or materials for corrosion and fatigue resistance. Our sealed designs also protect against dust and moisture, crucial for varied climate.

Q3: Are GBC chains compliant with safety and quality standards?

A3: While GBC is a global manufacturer, our products are meticulously crafted using professional manufacturing techniques and subjected to rigorous quality control measures, aligning with international best practices. We emphasize features that meet the spirit of Australian Standards, such as high tensile strength, fatigue resistance, and durability, which are critical for safety and performance in the mining context.

Q4: Can GBC provide customized chain solutions for specific mining equipment?

A4: Absolutely. GBC specializes in customized solutions, collaborating with clients to provide tailored cutter drive chains, sprockets, and conveyor chains. Our “Customised Series” features replaceable alloy tooth tips and modular link structures for adaptability, addressing unique operational requirements and integration with advanced mining technologies like automation and robotics.

Q5: How do GBC chains contribute to operational efficiency and cost reduction?

A5: GBC chains are designed for consistent chain lifespan, reduced downtime, and less complexity of maintenance. Features like self-lubricating options, modular designs, and superior wear resistance minimize the need for frequent servicing and replacements. This directly translates to lower operational costs, increased productivity, and enhanced overall efficiency for mining operations.