Mining Power Transmission Parts

GBC delivers a complete range of heavy-duty mining power transmission parts, engineered by Ever-power to withstand harshest conditions. We provide robust, reliable solutions to boost your operational uptime and productivity.

Our Mining Power Transmission Solutions

From colossal conveyor systems to the toughest mining chains, our products form the backbone of the most demanding mining operations.

DA Series Single Strand Conveyor Chains

Exceptional durability for continuous miners, borer miners, and road headers in demanding underground environments.

K Series Ladder Conveyor Chains

High-efficiency double-strand scrap chains for rapid material extraction in shuttle cars and feeder breakers.

TC Series Crawler Chains

Extended service life and superior durability for the crawler tracks of underground mining machinery.

AF Series Apron Feeder Chains

Robust, high-impact chains for handling heavy, abrasive, or large-sized materials with controlled flow.

G Series Bucket Elevator Chains

High-strength, fatigue-resistant chains for vertical transportation of bulk materials at fast elevating speeds.

DF Series Drop Forged Chains

Superior strength and wear resistance for conveying abrasive materials like ore and coal in the toughest conditions.

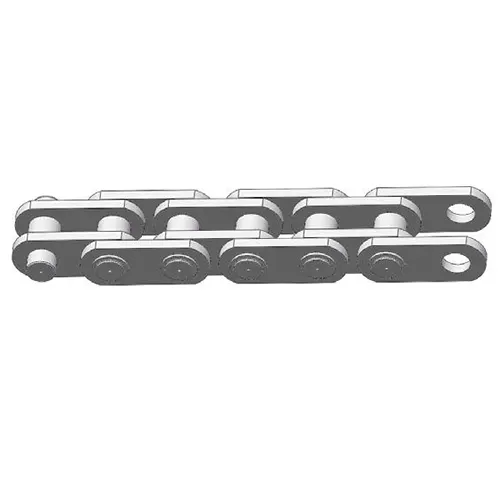

H Series Transmission Chains

Heavy-duty roller chains for power transmission in high-load, high-shock, and abrasive mining environments.

HD Series Heavy Duty Drive Chain

Thickened side plates for increased fatigue resistance and load strength, suitable for low-speed, high-shock applications in heavy equipment and mining environments.

DP Series Deep Pan Conveyor Chain

Heavy-duty chains for horizontal or inclined transport of bulk materials, offering robust construction to handle abrasive loads with durability in mining environments.

O Series Round Link Chain

High-strength steel chains with interconnected round links, designed for underground coal mining to resist abrasion, corrosion, and fatigue in harsh conditions.

Motor Grader Chain

Durable traction chains for motor graders, providing enhanced grip and protection on uneven mining surfaces to improve stability under heavy loads.

Push Coke Chain

Robust drive chains for coking processes, resistant to high temperatures and stress for efficient material pushing with minimal wear in metallurgical operations.

Applications & Industry Scenarios

GBC’s mining power transmission parts offer versatility across the entire mining lifecycle. We provide robust solutions for diverse applications, from underground extraction to surface processing and specialized equipment.

GBC’s diverse product lines form a comprehensive ecosystem of power transmission solutions, from extraction to processing and specialized tasks. This broad applicability positions GBC as a one-stop-shop for Australian mining needs, simplifying procurement and ensuring compatibility for clients.

The GBC Advantage: Engineered for Durability

Our commitment to quality is built on a foundation of superior materials, precision engineering, and rigorous testing. This is how we ensure every GBC component delivers a lower total cost of ownership.

Advanced Metallurgy

We use selected premium qualified steels and high-strength alloys. Processes like special heat-treatment for pins and induction hardening for teeth create components with superior wear resistance and structural integrity.

Precision Manufacturing

With over 20 years of manufacturing experience, Ever-power’s state-of-the-art facilities ensure every component is built to exact tolerances for perfect fitment, smooth operation, and extended service life.

Rigorous Quality Assurance

From raw material inspection to final performance testing, every product undergoes a multi-stage quality control process to guarantee it meets the highest international and Australian standards.

Customer Testimonials

These testimonials highlight how GBC’s tailored solutions address specific operational challenges, contributing to enhanced performance and reliability.

Western Australia – Iron Ore Mine

“Our iron ore operations in the Pilbara region demand components that can withstand relentless abrasive forces and extreme heat. We previously struggled with premature wear on conveyor idlers, leading to frequent replacements and significant downtime. It was a constant battle to keep our conveyors running efficiently, and the costs associated with frequent part changes were substantial. Since switching to GBC’s heavy-duty idlers, specifically designed for such conditions, we’ve seen a remarkable increase in lifespan. This has drastically reduced our maintenance schedule, freeing up our teams for other critical tasks, and boosting our daily output of iron ore. The local support from GBC’s Perth team has been invaluable, providing quick delivery and expert advice whenever we’ve needed it, ensuring our operations remain smooth even in this challenging environment.”

Queensland – Underground Coal Mine

“In our underground coal mine in Queensland, reliability is non-negotiable. Our continuous miners are the heart of our production, relying on robust conveyor chains to move tons of material daily from the coal face. We consistently experienced issues with chain elongation and unexpected breakages with previous suppliers, which directly impacted our production targets and created safety concerns. GBC’s DA Series single strand chains have proven exceptionally reliable in these harsh conditions, with their specialized heat-treated pins enduring the constant stress and abrasive environment. Their Brisbane team’s responsiveness ensures we always have the right parts when we need them, minimizing costly interruptions and allowing us to maintain our operational rhythm without compromise.”

New South Wales – Quarry

“As a quarry operator in NSW, we face the challenge of efficiently handling various aggregate sizes, from fine sand to large rocks. We found that many off-the-shelf conveyor systems often required extensive modifications or simply failed to handle such diverse materials efficiently, leading to spillage and bottlenecks. GBC provided a tailored DTII fixed belt conveyor system, integrated with a mix of specialized rollers, that perfectly matched our unique needs. The initial investment was quickly recouped through significantly improved material flow and a dramatic reduction in spillage. This demonstrates GBC’s deep understanding of practical operational challenges in quarrying and their ability to deliver solutions that genuinely enhance efficiency.”

South Australia – Processing Plant

“Our processing plant in South Australia requires precise material handling to maintain the quality of our finished products. We had ongoing issues with our bucket elevator chains and sprockets, which led to inconsistent material flow and increased wear on other critical components. This was causing bottlenecks in our processing line and impacting our overall efficiency. GBC’s G Series bucket elevator chains and SD Series segmental sprockets provided a seamless upgrade to our system. The ease of installation of the segmental sprockets drastically cut down our maintenance time, allowing for faster repairs. The improved chain performance has since optimized our entire vertical transport system, ensuring consistent material feed and contributing to a higher quality output. It’s a testament to GBC’s engineering and product quality.”

FAQs

Addressing common questions to further establish GBC’s expertise and provide valuable information.

What types of mining power transmission parts does GBC supply?

GBC provides a comprehensive range of mining power transmission parts. This includes various belt conveyor systems (universal, fixed, high-angle, mobile, screw), essential conveyor components (drive drums, bend pulleys, idlers, rollers, cleaners, take-ups), and a specialized portfolio of heavy-duty mining chains (DA, K, TC, AF, DP, O, G, DF, H, HD series etc.), as well as segmental sprockets and specialty chains for motor graders and push coke applications.

How does GBC ensure the durability of its mining power transmission parts?

GBC ensures the exceptional durability of its products through a multi-faceted approach. This includes the exclusive use of selected premium-grade alloy steels, the application of advanced heat treatment processes (such as special heat-treated pins and induction hardened teeth), precision engineering in design and manufacturing, and rigorous multi-stage quality assurance protocols. These measures are specifically designed to enable components to withstand the high stresses, severe abrasion, and harsh environmental conditions typical of Australian mining operations.

Are GBC's products compatible with existing mining equipment?

Many of GBC’s products are designed as direct replacements or are dimensionally interchangeable with Original Equipment Manufacturer (OEM) equipment, ensuring seamless integration into existing systems. GBC also offers comprehensive customization services. This allows for the design and manufacturing of bespoke solutions that ensure perfect compatibility and optimal performance with specific machinery and unique operational requirements.

How does GBC support Australian mining operations?

As the Australian sales agent for Ever-power Group Co., Ltd., GBC provides dedicated localized sales and technical support, ensuring responsive customer service and fast delivery of critical components. GBC’s team possesses a deep understanding of Australian mining conditions and industry standards, enabling them to offer solutions that are precisely tailored to the local context. The company is committed to building long-term partnerships based on mutual trust and shared success with its Australian clients.

Can GBC provide customized power transmission solutions for unique mining challenges?

Yes, GBC specializes in providing custom-engineered solutions for complex and unique mining challenges. GBC’s expert team can collaborate closely with clients to design and manufacture bespoke power transmission components and systems. These solutions are precisely tailored to specific site requirements, unique material properties, and challenging environmental conditions, ensuring optimal performance where standard products may not suffice.

Complementary Products & Solutions from GBC

GBC offers comprehensive power transmission solutions, simplifying procurement and ensuring system compatibility.

Chains & Sprockets

We offer a full range of sprockets designed to mesh with our heavy-duty mining chains, ensuring optimal power transmission and longevity.

Conveyor Systems & Components

We supply high-performance components like drive drums, bend pulleys, and various idlers and rollers, engineered for seamless integration and enhanced efficiency.

Bearings

GBC offers general bearings, lubrication solutions, and reliability products, crucial for optimal operation and extended lifespan of all power transmission components.

Partner with Your Power Transmission Expert

Elevate your mining operations with GBC’s superior power transmission solutions. Our commitment to quality, performance, and local support ensures peak efficiency and productivity across Australian sites. As Ever-power Group Co., Ltd.’s trusted Australian sales agent, GBC combines global manufacturing excellence with responsive, localized service. This dual advantage provides high-performance, durable components for Australia’s harsh conditions, backed by expert technical support and efficient logistics. Contact GBC today at sales@australia-drive.com to optimize your power transmission systems.