16B-1 European Standard Finished Bore Sprocket

The 16B-1 European Standard Finished Bore Sprocket is engineered for exceptional durability and performance in various applications. This high-quality sprocket features a precision finish, ensuring optimal fit and functionality with your chain system. Manufactured according to strict European standards, it provides reliable operation in demanding environments. Whether for industrial machinery or agricultural equipment, our sprocket guarantees longevity and efficiency.

GBC proudly offers the 16B-1 European Standard Finished Bore Sprocket in Australia, ensuring top-quality products for our customers.

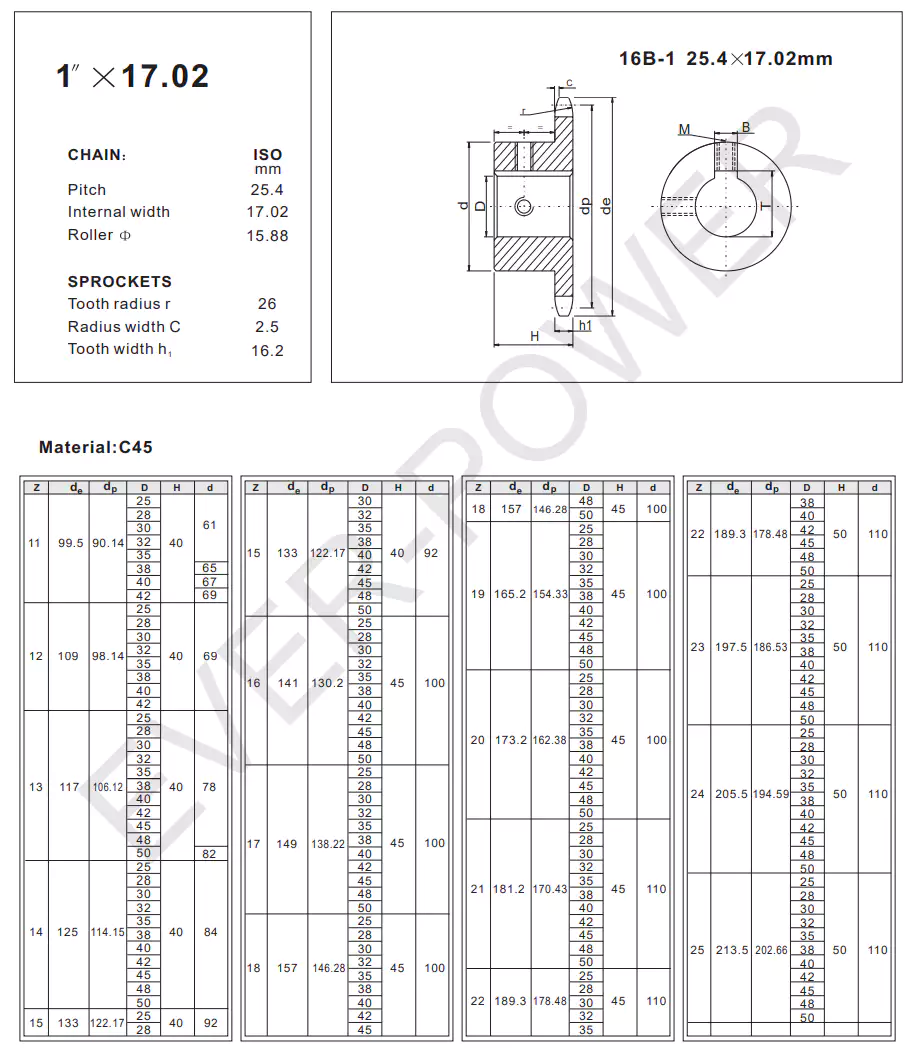

Specifications of 16B-1 European Standard Finished Bore Sprocket

A finished bore sprocket is a crucial component in power transmission systems. It features a wheel with teeth around its edge, designed to engage with a chain or belt to transfer power and motion between shafts. The 16B-1 European Standard represents a specific type of finished bore sprocket frequently utilized in industrial settings.

Materials and Manufacturing Process

Our finished bore sprockets are crafted from high carbon, alloy, or stainless steel, tailored to meet specific application requirements. The manufacturing process involves several stages, including material selection, cutting, stamping, forging, machining, heat treatment, surface hardening, surface treatment, and quality inspection.

- Material selection: We select materials based on necessary strength, durability, and corrosion resistance.

- Cutting: Raw materials are shaped and sized according to specifications.

- Stamping and Forging: The sprocket is shaped through stamping or forging to ensure strength.

- Machining: Advanced techniques are used for drilling, turning, milling, and boring the sprocket.

- Heat treatment: The sprocket undergoes heating followed by rapid quenching to enhance hardness.

- Surface hardening: Techniques like carburizing or induction hardening improve wear resistance.

- Surface treatment: Coatings or plating are applied to prevent rust and corrosion.

- Quality inspection: The sprocket is rigorously tested to confirm compliance with standards.

Applications of Plate Wheel Sprockets

Plate wheel sprockets find extensive use in heavy-duty industrial applications, including heavy machinery, food processing and packaging, chemical and pharmaceutical sectors, assembly lines, logistics, and warehousing. They work effectively with roller chains or conveyor chains for reliable power transmission.

Maintenance and Troubleshooting

To ensure optimal performance and longevity, proper maintenance and regular inspection of the finished bore sprocket are essential. Important maintenance tips include:

- Daily inspection: Look for signs of wear or damage, such as cracks or bent teeth.

- Cleaning: Remove dirt, debris, or grease that has accumulated on the sprocket.

- Lubrication: Use a suitable lubricant to minimize friction and wear.

- Adjustment and Calibration: Periodically check the chain's alignment and tension, adjusting as necessary.

Common issues with plate wheel sprockets include skipping teeth, breakage, wear, excessive noise, and chain disengagement. Solutions to these problems include:

- Skipping teeth: Check for misalignment or chain tension; adjust or replace the chain as needed.

- Breakage: Inspect the sprocket for wear or damage and replace if necessary.

- Wear: Monitor for deformation and replace if needed.

- Excessive noise: Inspect for misalignment or lubrication; adjust or lubricate as needed.

- Chain disengagement: Check for misalignment or tension issues and adjust or replace the chain accordingly.

Other Types of Sprockets and Chains

Besides finished bore sprockets, we provide various other sprocket types, including taper lock sprockets, QD sprockets, and idler sprockets. Additionally, we offer an array of chain types and models to meet diverse client needs.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, a leading manufacturer in the power transmission industry. We specialize in a wide range of products, including the 16B-1 European Standard Finished Bore Sprocket. Our sprockets are crafted with precision and high-quality materials, ensuring durability and reliability in various applications.

In addition to our standard sprockets, we offer customized solutions tailored to meet specific customer requirements. We invite clients to provide their designs or samples for bespoke sprocket manufacturing. At GBC, we are committed to delivering exceptional products and services that cater to the unique needs of our customers.

Additional information

| Edited by | Sylvia |

|---|

The 16B-1 European Standard Finished Bore Sprocket is engineered for exceptional durability and performance in various applications. This high-quality sprocket features a precision finish, ensuring optimal fit and functionality with your chain system. Manufactured according to strict European standards, it provides reliable operation in demanding environments. Whether for industrial machinery or agricultural equipment, our sprocket guarantees longevity and efficiency.

GBC proudly offers the 16B-1 European Standard Finished Bore Sprocket in Australia, ensuring top-quality products for our customers.